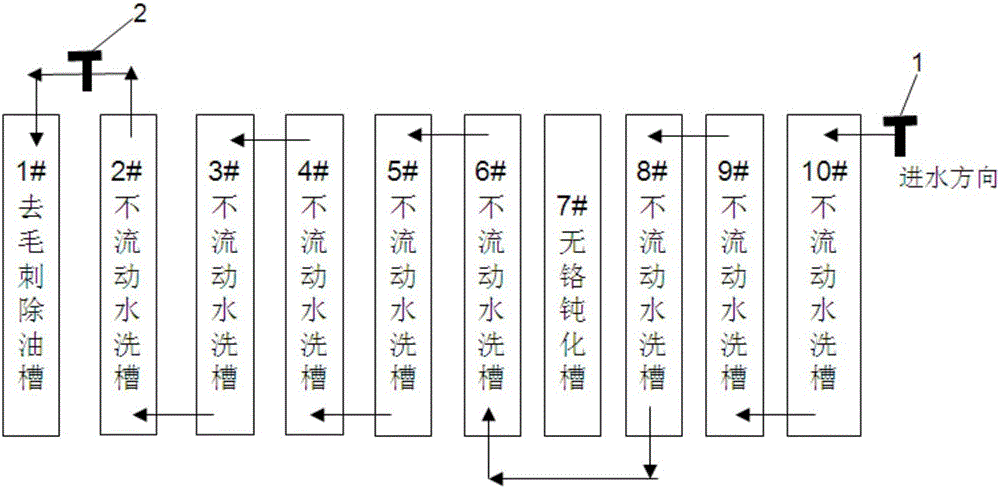

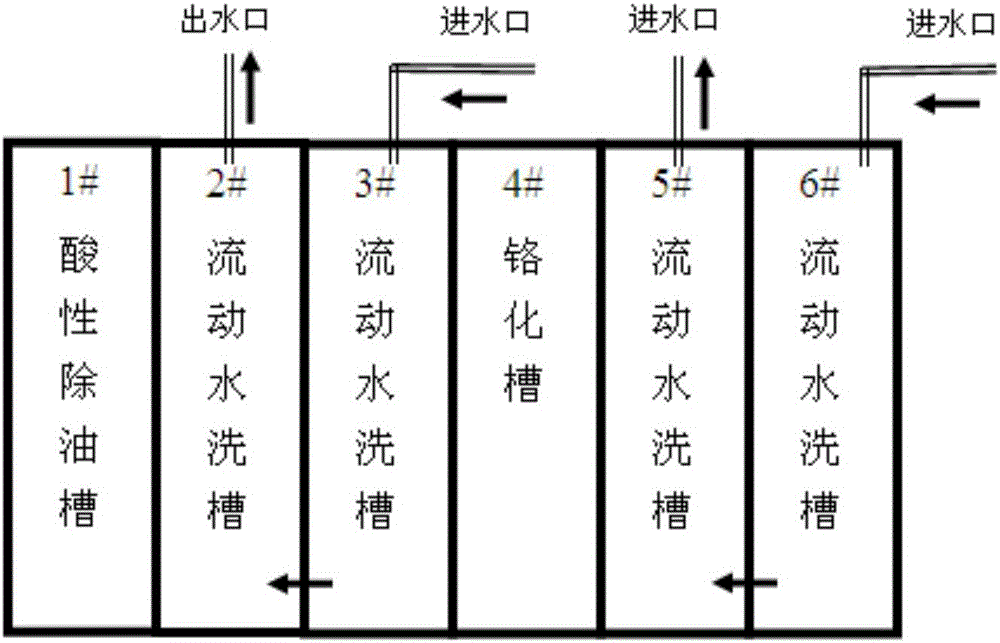

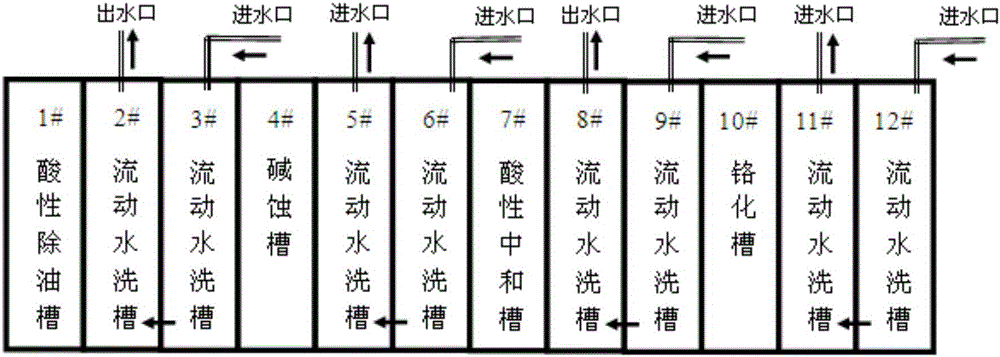

Aluminium alloy chromate-free overall agent compatibility treatment and wastewater zero discharge system

An aluminum alloy and zero-emission technology, which is applied in the coating process of metal materials, can solve problems such as pollution, polluted workshops, and long processes, and achieve the effect of simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Embodiment 1 (working parameters of deburring and degreasing tank)

[0118] Fluotitanic acid and fluozirconic acid (1:1) concentration 25g / L, polyacrylic acid (30%) concentration 5g / L, phosphonobutane tricarboxylic acid value (50%) 50g / L, temperature 25°C, acidity value 1.75 equiv.

Embodiment 2

[0119] Embodiment 2 (working parameters of deburring and degreasing tank)

[0120] Fluotitanic acid and fluozirconic acid (1:1) concentration 20g / L, polyacrylic acid (30%) concentration 5g / L, phosphonobutane tricarboxylic acid value (50%) 50g / L, temperature 25°C, acidity value 1.75 equiv.

Embodiment 3

[0121] Embodiment 3 (working parameters of deburring and degreasing tank)

[0122] Fluotitanic acid and fluozirconic acid (1:1) concentration 30g / L, polyacrylic acid (30%) concentration 5g / L, phosphonobutane tricarboxylic acid value (50%) 50g / L, temperature 25°C, acidity value 1.75 equiv.

[0123] Chromium-free passivation treatment on the aluminum alloy surface can be achieved. From Examples 1-3, as the concentration of fluorotitanic acid and fluorozirconic acid (1:1) increases, the dissolving ability increases and the deburring ability increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com