Novel paint spraying equipment for steel pipes

A technology of spraying equipment and steel pipes, which is applied in the direction of spraying devices, etc., can solve the problems of low efficiency and high labor costs, and achieve the effects of improving painting efficiency, increasing spraying effect, and ensuring spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

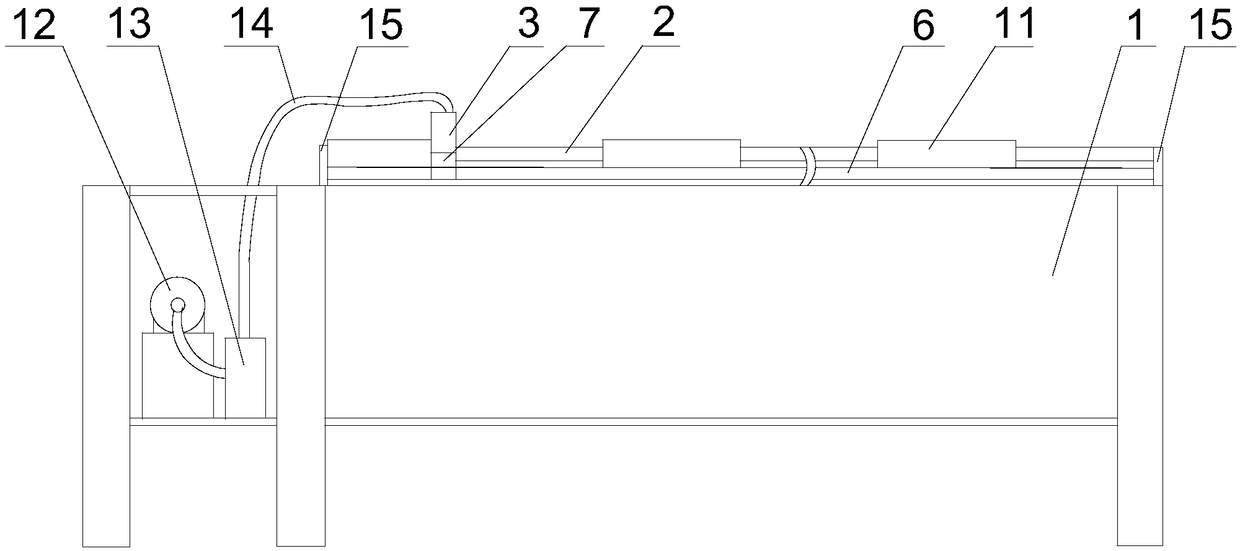

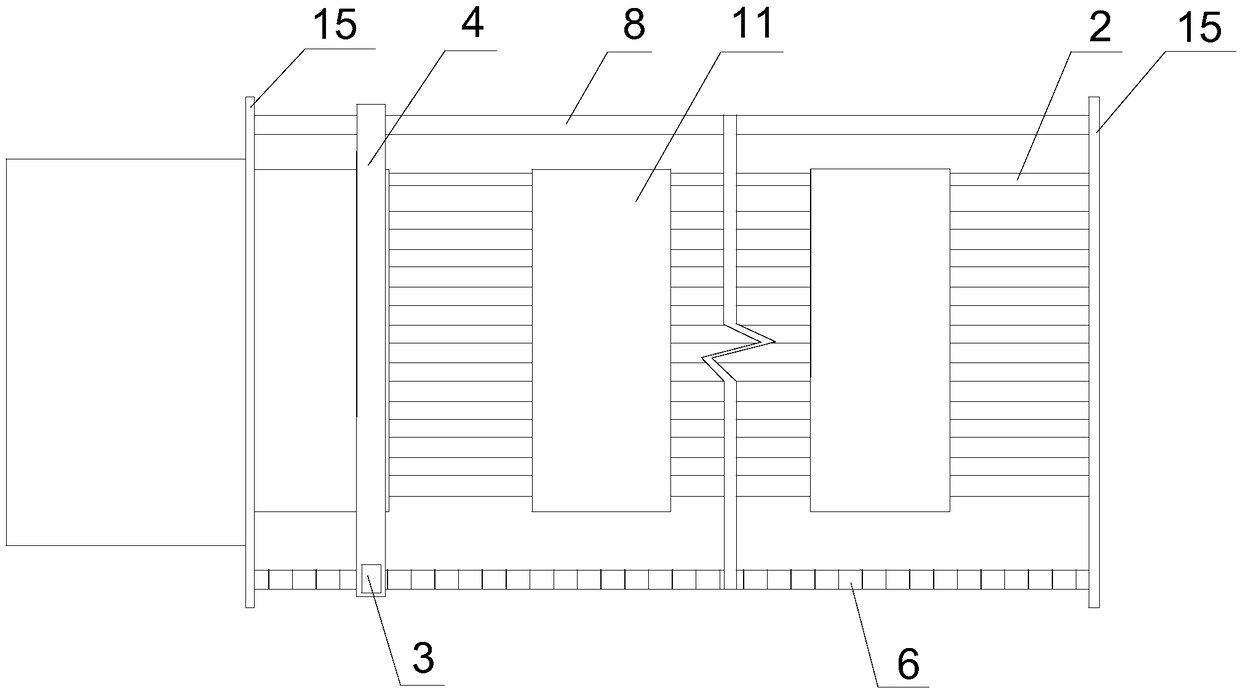

[0038]The invention provides a new type of steel pipe painting equipment, including a workbench 1, which can be set up to be composed of a tabletop and outriggers. Laying in parallel does not limit whether the height of the horizontal plane where the steel pipes 2 are located is consistent or whether the adjacent steel pipes 2 are in contact; it also includes the moving mechanism I that moves axially along the steel pipe 2 and the moving mechanism II that moves radially along the steel pipe 2, the moving mechanism I or The paint spray gun 3 is arranged on the moving mechanism II, and the paint spray gun 3 is driven to move along the axial and radial directions of the steel pipe 2 through the cooperation of the moving mechanism I or the moving mechanism II. A moving mechanism I that moves axially along the steel pipes 2 is provided to ensure that the paint spray gun 3 sprays the same color or different colors along the axial direction of each steel pipe 2; a moving mechanism II ...

Embodiment 2

[0040] Further improvement on the basis of Example 1, if the paint spray gun 3 is set on the moving mechanism I, the paint spray gun 3 is driven by the moving mechanism I to move axially along the steel pipe 2, and the moving mechanism I and the paint spray gun 3 are driven by the moving mechanism II to move along the steel pipe 2 radial movement; if the paint spray gun 3 is set on the moving mechanism II, the paint spray gun 3 is driven by the moving mechanism II to move radially along the steel pipe 2, and the moving mechanism II and the paint spray gun 3 are driven by the moving mechanism I to move axially along the steel pipe 2.

[0041] Whether the paint spray gun 3 is set on the moving mechanism I or the paint spray gun 3 is set on the moving mechanism II, the continuous movement of the paint spray gun above the steel pipe 2 along the axial and radial directions of the steel pipe 2 can be realized, which is convenient for spraying the steel pipe 2 according to the requirem...

Embodiment 3

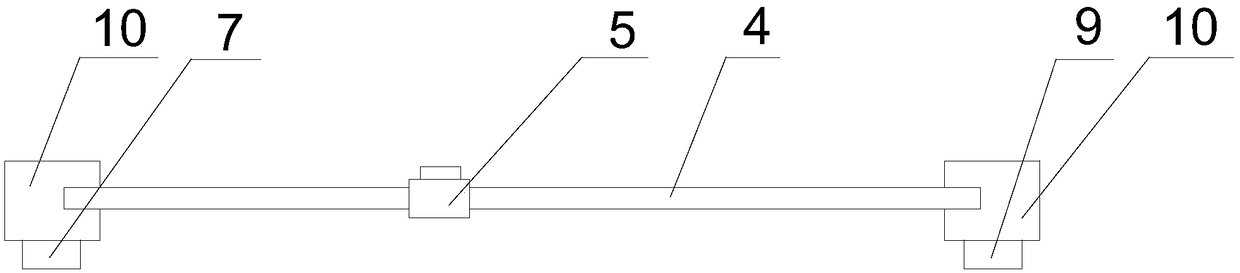

[0043] Further improvement on the basis of embodiment 2, the moving mechanism I or moving mechanism II for installing the paint spray gun 3 adopts a ball screw mechanism, and the moving mechanism II or moving mechanism I adopts a gear and rack mechanism. Since the paint spray gun 3 is used for the spraying operation, the reciprocating operation of the moving mechanism Ⅰ or moving mechanism Ⅱ used to install the paint spray gun 3 is relatively more frequent. In order to ensure the painting control accuracy and operation stability, a ball screw mechanism is used to drive the paint spray gun. 3 painting operations.

[0044] As an optimal solution, the moving mechanism II for installing the paint spray gun 3 adopts a ball screw mechanism to drive the paint spray gun 3 to move radially along the steel pipe 2, and the moving mechanism I uses a gear and rack mechanism to drive the moving mechanism II and the paint spray gun 3 Move along the axial direction of steel pipe 2. Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com