Wood floor chamfering and paint spraying device and application method thereof

A wood floor, chamfering technology, applied in the direction of spray device, device for coating liquid on the surface, pretreatment surface, etc., can solve the problems of uneven paint roller coating, slow painting speed, environmental pollution, etc. Faster, reduce waste, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

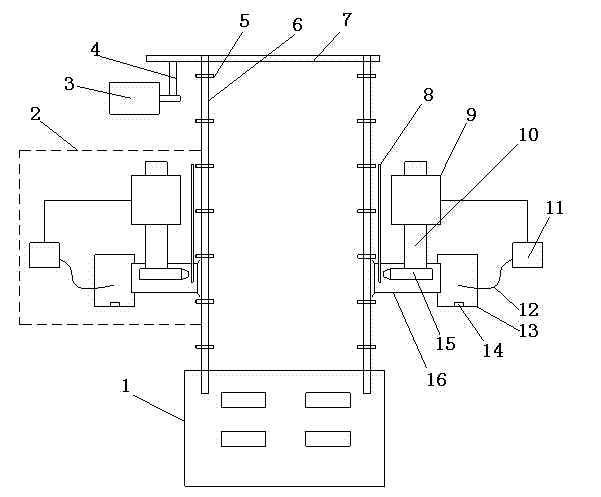

[0013] Example. Wooden floor chamfering and painting installation, constituted as figure 1 Shown, comprise a pair of transmission chains 6 that are arranged in parallel, one end of two transmission chains 6 is connected through main transmission shaft 7, and main transmission shaft 7 is provided with drive motor 3 through chain 4, and described each transmission chain 6 is provided with Spacers 5 arranged at the same interval, UV light curing machine 1 is provided at the tail of the pair of transmission chains 6, and a chamfering surface painting mechanism 2 is provided on both sides of a pair of transmission chains 6; the chamfering surface painting mechanism 2 includes Through the UV paint sprayer 15 that support is inclined, the UV paint sprayer 15 can spray paint by the paint pump, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com