Power distribution cabinet framework

A technology for power distribution cabinets and frames, applied in the field of power distribution cabinet frames, can solve the problems of increased damage to busbar clamps 10, lower product quality, and increased costs, and achieve the effects of high stability, good strength, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

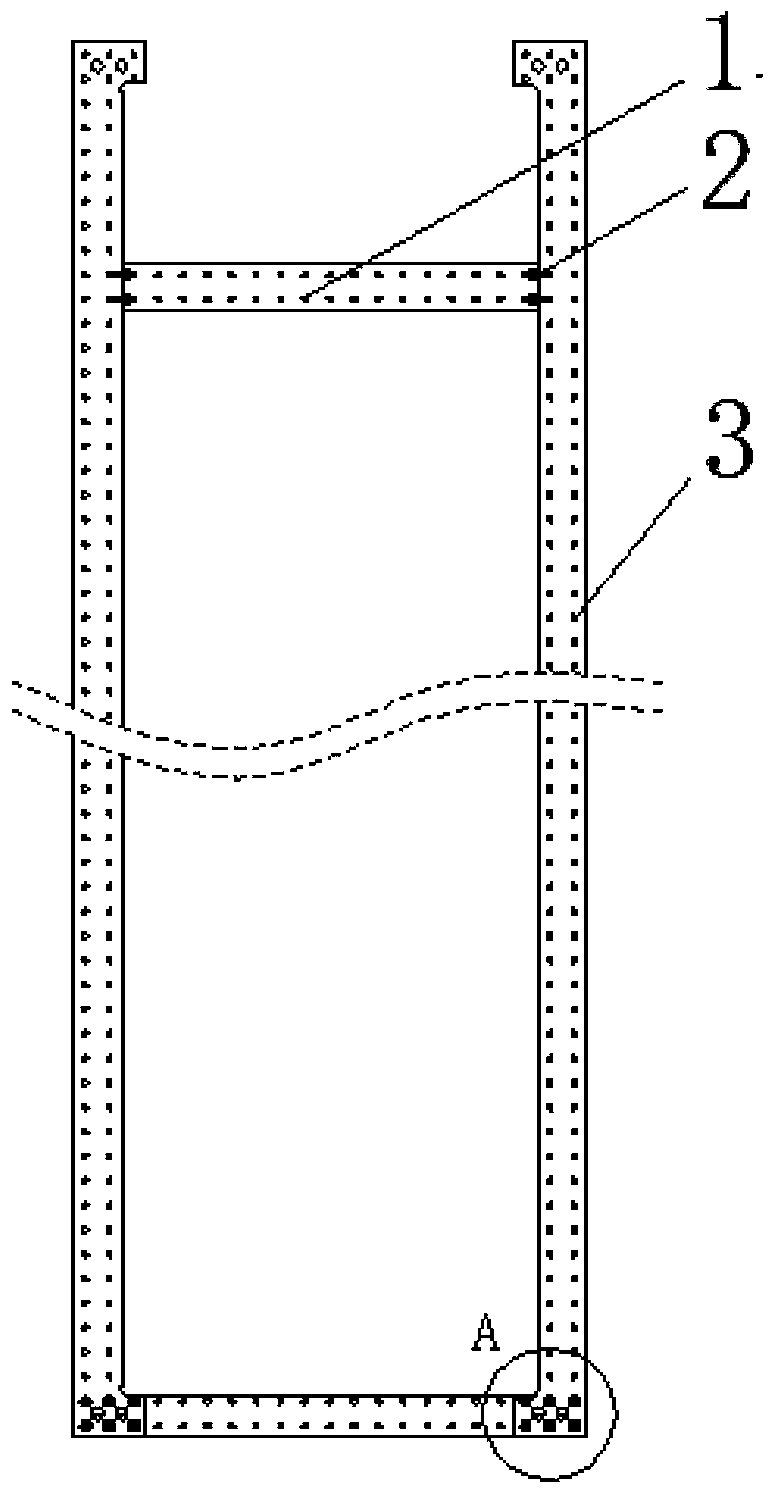

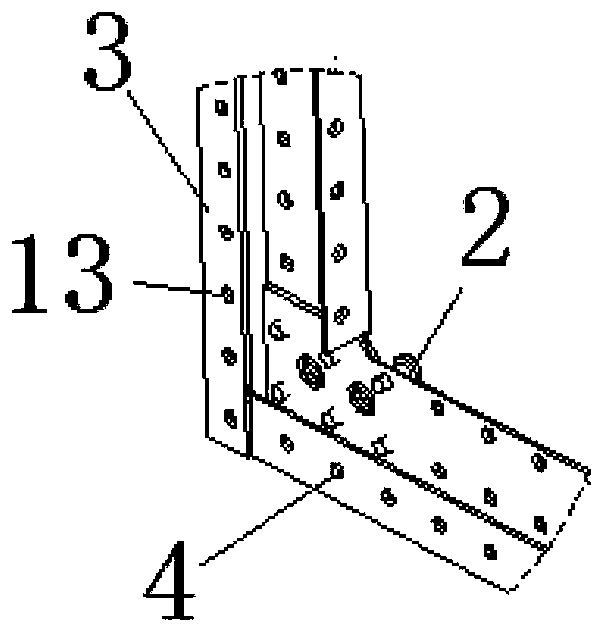

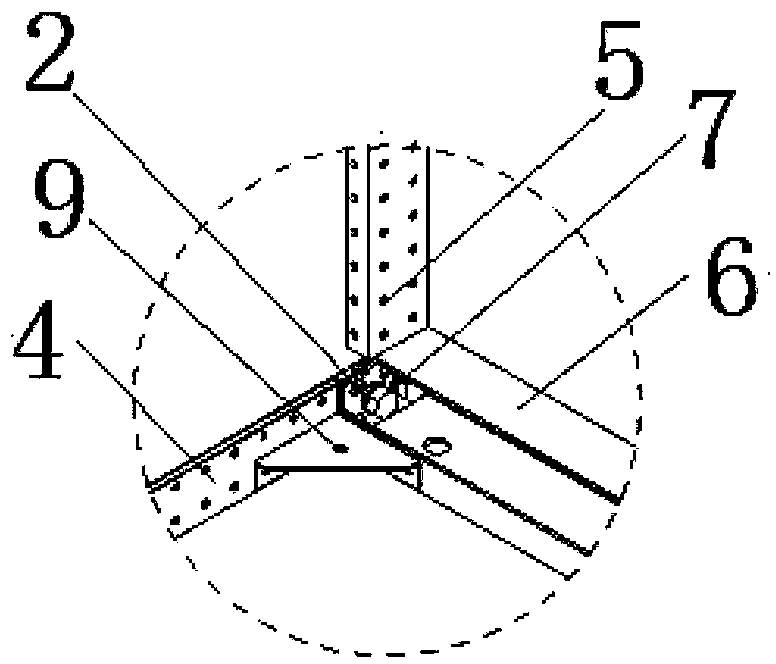

[0039] figure 1 and figure 2 It is a structural schematic diagram of the side panel of the distribution cabinet frame of the present invention; image 3 It is a schematic diagram of the installation of the side piece and the connecting beam of the distribution cabinet frame of the present invention; Figure 4 It is a schematic diagram of the installation of the flip-top cover plate and the cabinet body of the power distribution cabinet frame of the present invention; Figure 5 It is a structural schematic diagram of the frame of the distribution cabinet of the present invention; Figure 6 It is a schematic structural diagram of a power distribution cabinet assembled from a frame of the power distribution cabinet according to the present invention.

[0040] Such as figure 1 and fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com