Formaldehyde-free aqueous jointing agent and preparation method therefor

A jointing agent, water-based technology, applied in the field of formaldehyde-free water-based jointing agent, can solve the problems of strong pungent odor, endangering human health and environmental safety, etc., and achieve the effect of not easy to hang, easy to construct, and fast to set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

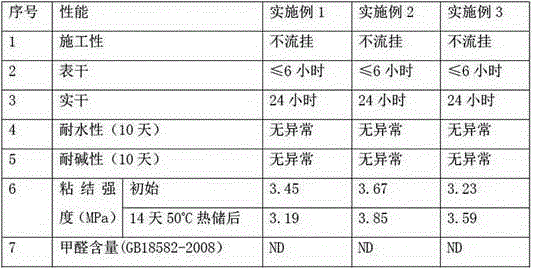

Examples

preparation example Construction

[0069] The preparation method of above-mentioned formaldehyde-free aqueous jointing agent, comprises the following steps:

[0070] Preparation of the main agent: disperse the above-mentioned water-based epoxy resin, antifreeze agent, dispersant, wetting agent and defoamer at a medium speed for 5-10 minutes until uniform, and then add the above-mentioned main agent by weight of talc Powder, quartz sand, heavy calcium, attapulgite and wood fiber, disperse at medium and high speed for 10-20 minutes until uniform, and finally slowly add deionized water of the above main agent by weight to adjust the viscosity, and stir evenly.

[0071] Preparation of curing agent: disperse the water-based epoxy curing agent, antifreeze agent, dispersant, wetting agent and defoamer at a medium speed for 5-10 minutes to uniformity by weight of the above curing agent, and then add the above curing agent by weight Talc powder, quartz sand, heavy calcium, attapulgite and wood fiber, disperse at medium ...

Embodiment 1

[0074] A formaldehyde-free water-based jointing agent, which is made by mixing the main agent and curing agent, including:

[0075] The main agent is composed of the following components by weight:

[0076] Waterborne epoxy resin 17.50

[0077] Antifreeze 1.00

[0078] Dispersant 0.50

[0079] Wetting agent 0.30

[0080] Defoamer 0.20

[0082] Quartz sand 10.00

[0083] Heavy calcium 43.00

[0084] Attapulgite 0.80

[0085] Wood fiber 0.70

[0086] Deionized water 6.00

[0087] Curing agent is made up of following components by weight:

[0088] Waterborne epoxy curing agent 16.00

[0089] Antifreeze 0.50

[0090] Dispersant 0.30

[0091] Wetting agent 0.30

[0092] Defoamer 0.20

[0094] Quartz sand 12.00

[0095] Heavy calcium 33.00

[0096] Attapulgite 0.80

[0097] Wood fiber 0.70

[0098] Hydroxyethylcellulose 0.40

[0099] Deionized water 10.80

[0100] The mixing ratio of the above-mentioned main a...

Embodiment 2

[0106] A formaldehyde-free water-based jointing agent, which is made by mixing the main agent and curing agent, including:

[0107] The main agent is composed of the following components by weight:

[0108] Water-based epoxy resin 22.00

[0109] Antifreeze 1.20

[0110] Dispersant 0.60

[0111] Wetting agent 0.40

[0112] Defoamer 0.40

[0113] Talc powder 12.00

[0114] Quartz sand 10.00

[0115] Heavy calcium 41.00

[0116] Attapulgite 0.80

[0117] Wood fiber 0.70

[0118] Deionized water 10.90

[0119] Curing agent is made up of following components by weight:

[0120] Waterborne epoxy curing agent 20.50

[0121] Antifreeze 0.50

[0122] Dispersant 0.60

[0123] Wetting agent 0.40

[0124] Defoamer 0.30

[0125] Talc powder 25.00

[0126] Quartz sand 12.00

[0127] Heavy calcium 26.50

[0128] Attapulgite 0.70

[0129] Wood fiber 0.60

[0130] Hydroxyethylcellulose 0.50

[0131] Deionized water 12.40

[0132] The mixing ratio of the above-mentioned ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com