Thickening agent used for aqueous vibration absorbing material

A technology of shock-absorbing materials and thickeners, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as cracking of coating films, reduction of importance, and inability to precisely form coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

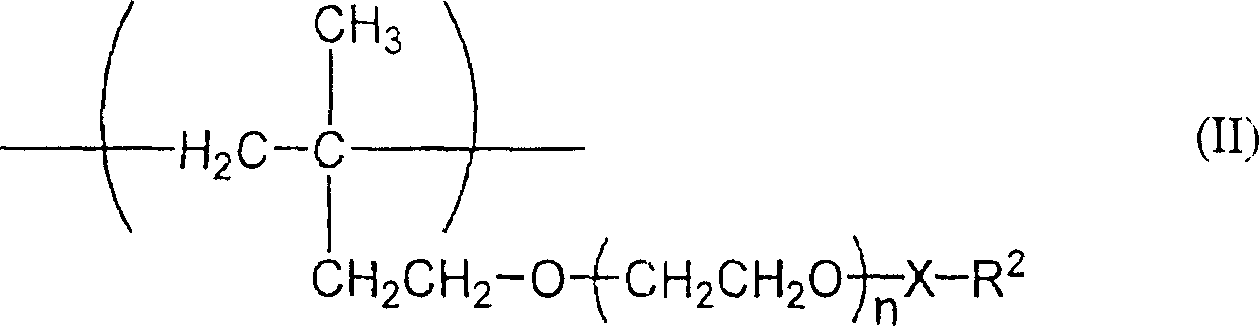

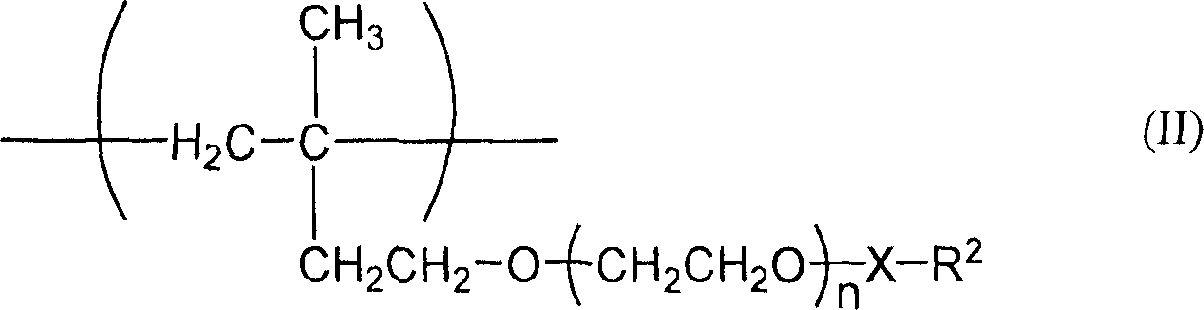

[0071] [Example 1: Synthesis of a polymer having a basic-soluble monomer unit and an associative monomer unit]

[0072] In a four-necked separable flask with stirrer, thermometer, refrigerator, nitrogen inlet tube, and dropping funnel, were charged deionized water (115 parts) and ammonium sulfonate of polyoxyethylene lauryl ether ( 1.5 servings). At an internal temperature of 68°C, the contents of the flask were stirred and gently purged with nitrogen until the interior of the reactor was sufficiently replaced with nitrogen. Ammonium sulfonate of polyoxyethylene lauryl ether (1.5 parts) was dissolved in deionized water (92 parts).

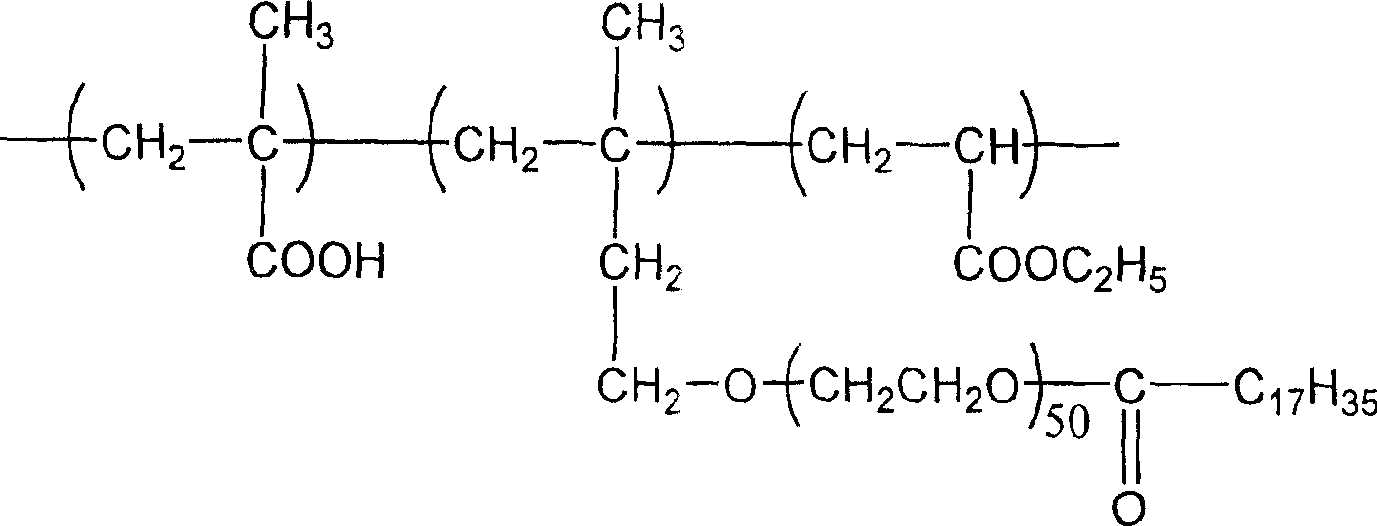

[0073] A mixture product (50 moles of ethylene oxide) of methacrylic acid (40 parts), ester and octadecyl polyoxyethylene (3-methyl-3-butenyl) ether as polymer monomer Adduct) (10 parts) and ethyl acrylate (50 parts) were added to the product solution, which were stirred together to prepare a pre-emulsion. By the way, said methacrylic acid is th...

Embodiment 2

[0076] [Example 2: Synthesis of a polymer having a basic-soluble monomer unit and an associative monomer unit]

[0077] The thickener that is used for damping material 2 is prepared according to the program of embodiment 1, uses the mixture product of methacrylic acid (40 parts), ester and octadecyl polyoxyethylene acrylate (50 moles of ethylene oxide Alkane adduct) (10 parts) and ethyl acrylate (50 parts) as polymer monomers to replace methacrylic acid (40 parts), ester and octadecylpolyoxyethylene (3-methyl - a mixture product of 3-butenyl) ether (adduct of 50 moles of ethylene oxide) (10 parts) and ethyl acrylate (50 parts).

Embodiment 3 and 4 and comparative Embodiment 2

[0080] [Examples 3 and 4 and Comparative Example 2: Preparation of Latex Coating Material for Shock Absorbing Material]

[0081] The latex coating material for shock-absorbing material, which is a composition for shock-absorbing material, is prepared by mixing the thickener for shock-absorbing material prepared in Examples 1 and 2 and Comparative Example 1 with other components were prepared in fractions, and the mixing ratios are shown below.

[0082] (The mixing ratio)

[0083] - Emulsion ("Acryset DC-172", manufactured by Nippon Shokubai Co. Ltd.) 148 parts

[0084] - Calcium carbonate ("NN#200", manufactured by Nitto Funka Kogyo K.K.) 240 parts

[0085] - Additive (propylene glycol) 19 parts

[0086] - Dispersant ("Demol EP", manufactured by Kao Co., Ltd.) 4.3 parts

[0087] -Thickener for shock-absorbing material 7 parts

[0088] - Defoamer (Nopuko 8034L", manufactured by San Nopuko K.K.) 0.3 parts

[0089] In Comparative Example 2, 14 parts of the thickener for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com