Metal water dripping line for preventing pollution of wall and wall bulging structure

A drip line and metal technology, applied in the direction of roof, roof drainage, roof covering, etc., can solve the problems of poor high temperature resistance, easy to foreigners, poor impact resistance, etc., to reduce weight, not easy to fall off, improve strength and The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

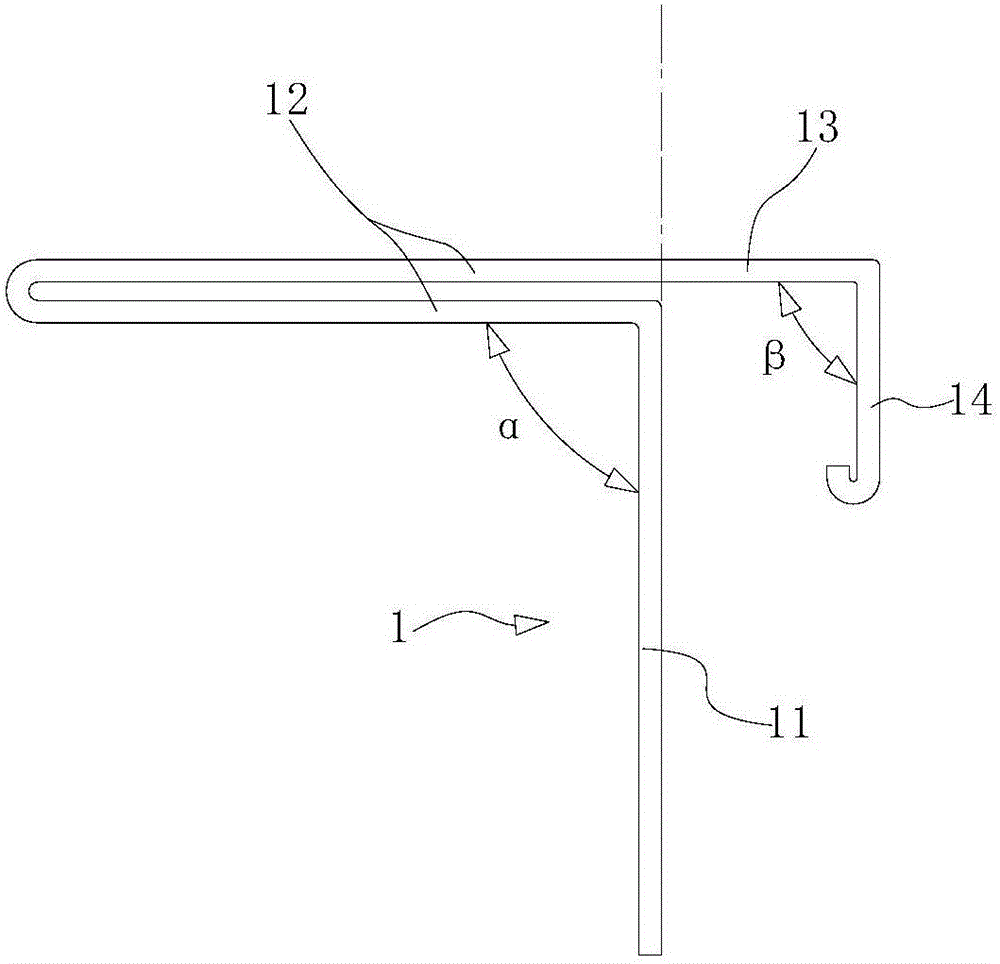

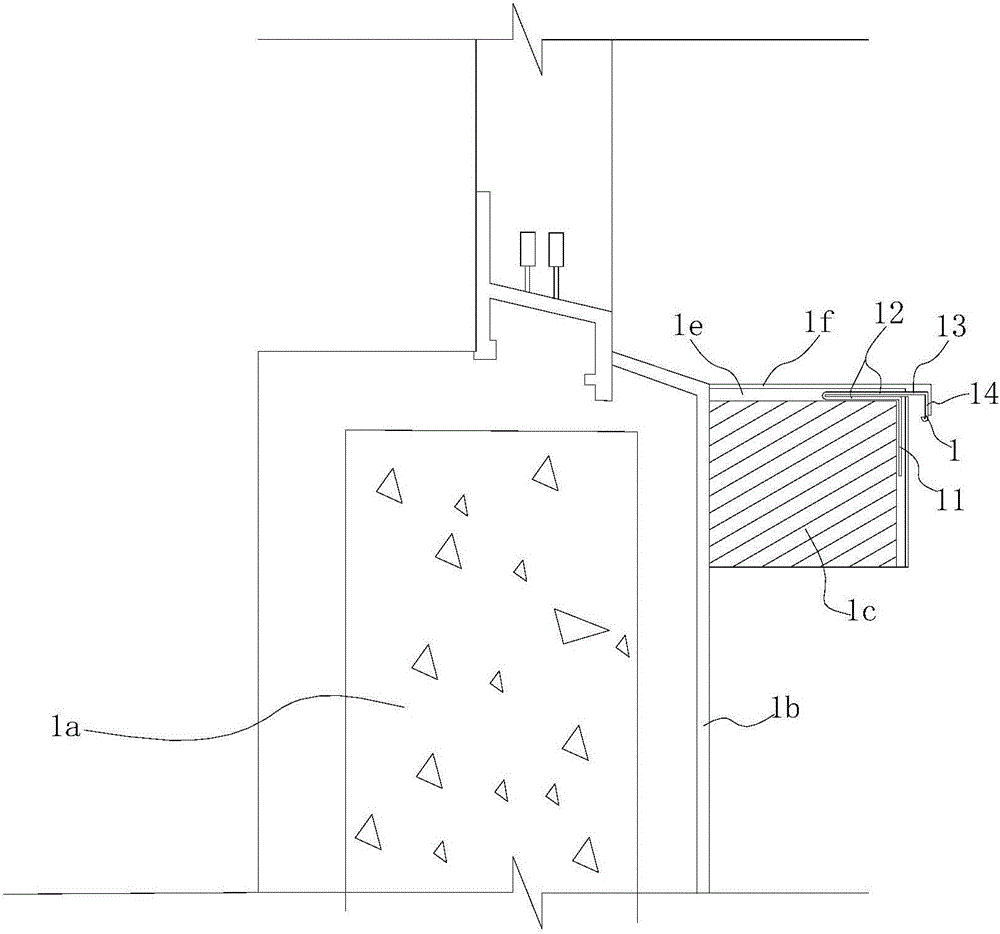

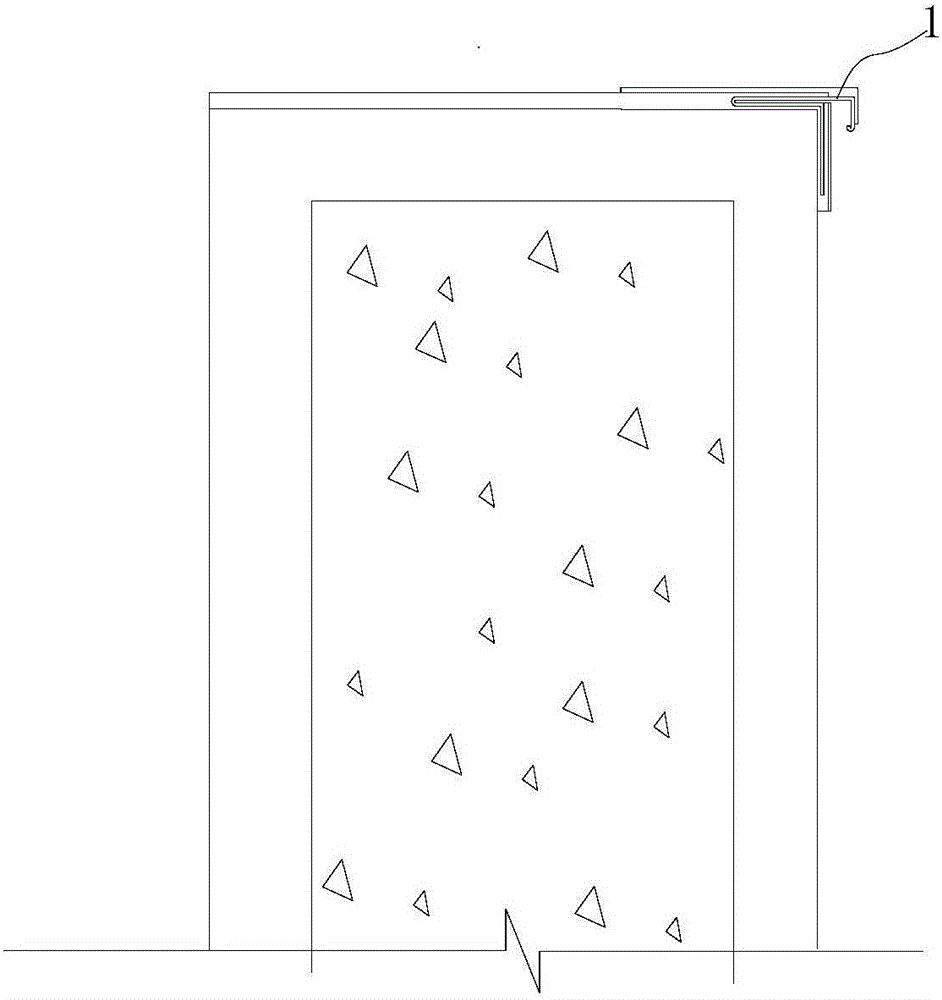

[0028] A metal drip line installed on the upper part of the protruding structure of the wall to prevent the wall and the protruding structure of the wall from hanging and polluting. 0°<α<180°; the intersecting ridges of the two attachment sheets are connected with an overhanging piece extending along the horizontal direction, and an outwardly overhanging piece is connected on the edge of the overhanging piece relative to the intersecting ridgeline For the deflector extending below, the diversion angle β between the deflector and the overhanging piece is α≤β<180°; the length of the deflector is equal to that of the attachment piece and the overhanging piece.

[0029] In this embodiment, the opening angle α of the metal drip line 1 is 90°, and the diversion angle β is 90°, as figure 1 As shown, the two attachment sheets 11, 12 of the metal drip line 1, the overhanging sheet 13 and the guide sheet 14 are an integral structure formed by bending a metal strip; Fold down 90° to for...

Embodiment 2

[0033] In Example 1, since the cement mortar layer 1e has a certain thickness and cannot be on the same level as the overhanging sheet 13, it needs to be leveled through the facing mortar layer 1f. The difference is: if Figure 4 to Figure 7 As shown, the overhanging sheet 24 of the metal drip line 2 passes through the turning sheet 23 above the intersecting ridgelines of the two attachment sheets 21, 22 (the creases of the two attachment sheets 21, 22 are the intersecting ridgelines). The attachment sheet 22 with double-layer structure is connected; the overhanging sheet 24 is turned up 90° at the intersecting ridge and then turned down 90° to form the turning piece 23, the turning piece 23 The height is 1-5mm. Such as Figure 4 and Figure 5 As shown, the attachment sheets 21, 22 are provided with some overflow holes 111; when the metal drip line 1 is pasted with cement mortar, the cement mortar can overflow from the overflow holes 111 of the attachment sheets, so that th...

Embodiment 3

[0036] The difference with embodiment 2 is: as Figure 8 to Figure 9 As shown, an obtuse angle is formed between the top surface of the wall protruding structure 1c and the exterior surface, the opening angle α between the two attachment sheets 31 of the metal drip line 3 is an obtuse angle, and the gap between the guide sheet 35 and the overhanging sheet 34 The diversion angle β can be chosen as 90°≤β≤165°, preferably, the best diversion effect has been proved by experiments when β=135°. It is worth noting that, regardless of whether the opening angle α is obtuse, right or acute, the diversion angle β can be any angle within 90°≤β≤165°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com