Device for assisting in welding process of LSAW pipe through pulse current and using method

A pulse current and welding process technology, applied in welding equipment, arc welding equipment, applications, etc., can solve the problems of uneven distribution of heat-affected zone, failure to reflect the toughness of welded joints, and uneven distribution of tissue in the heat-affected zone, so as to avoid The effects of high cost and low efficiency, refinement of coarse-grained grains, and enhancement of solid solution capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

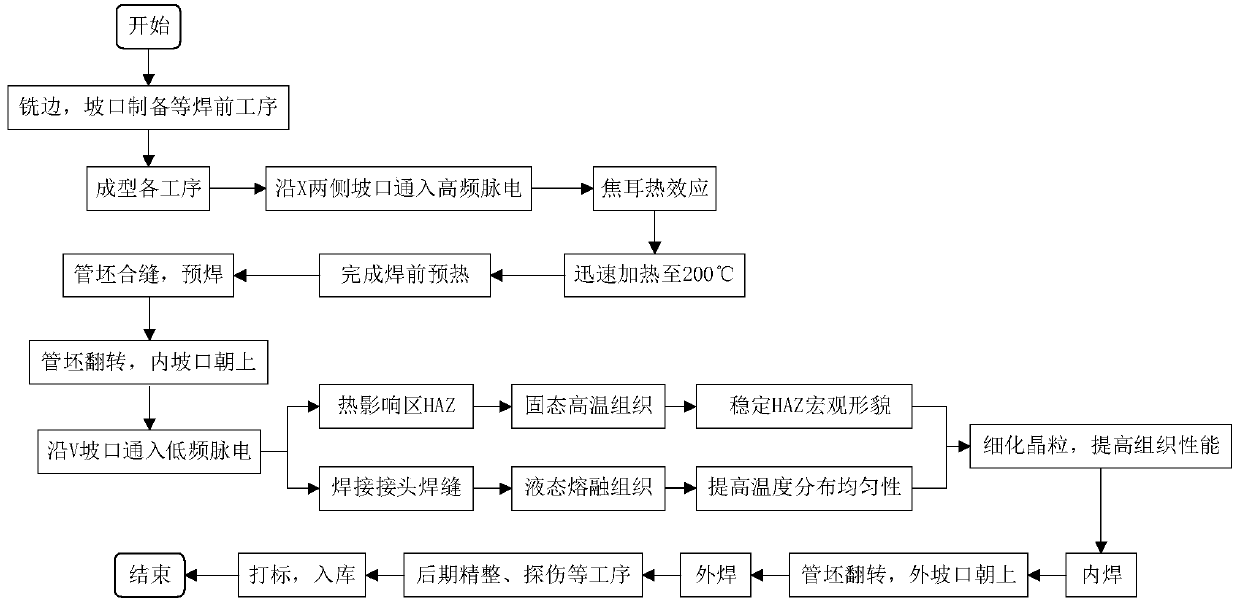

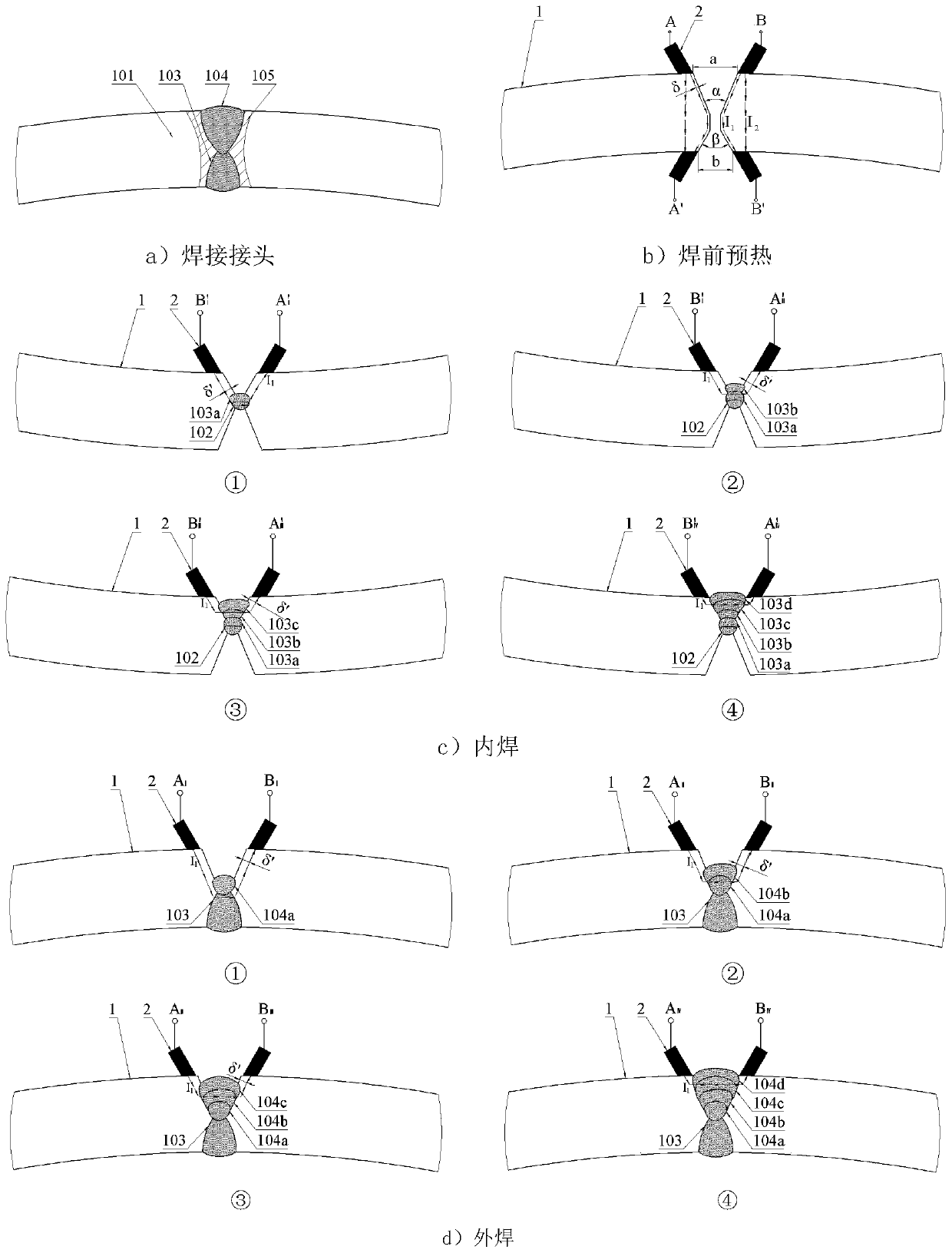

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0037] The present invention aims to provide a pulse current assisted welding process device and method for LSAW pipes to refine the structure of the heat-affected zone of the LSAW pipe and improve the uniformity of the distribution of the structure, thereby improving the overall welding quality of the welded joint and further improving the service life of the LSAW pipe. process reliability.

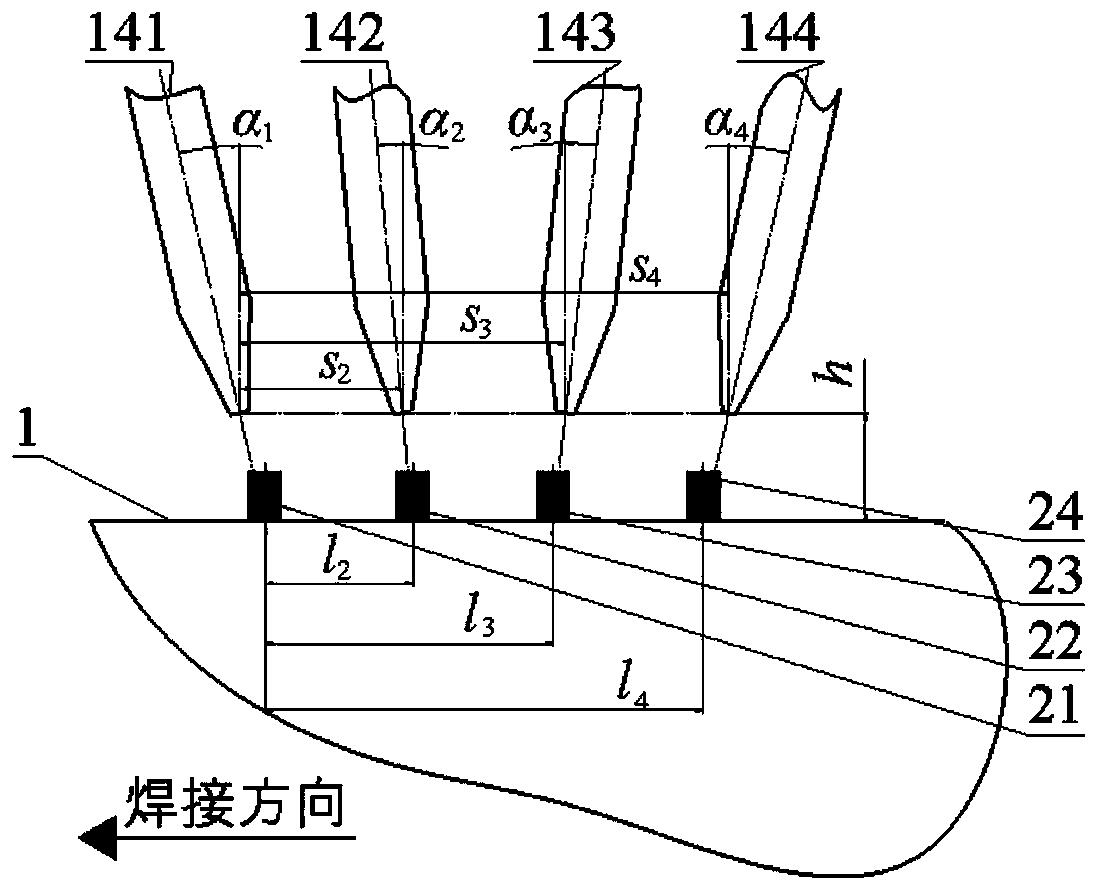

[0038] Such as Figure 4-7 As shown, a pulse current assisted LSAW pipe welding process device of the present invention includes graphite electrodes 2, base 4, beam 6, first bracket 7, second bracket 9, mounting ring 8 and mounting arm 10, nut 3 and the graphite electrode 2 are coaxially installed on the base 4, the graphite electrode 2 protrudes from the nut 3 at a distance of 15-20mm, a spring 15 is arranged between the graphite electrode 2 and the base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com