Aluminum oxide feeding system and method

A technology of alumina and blanking, which is applied in the field of aluminum electrolysis, can solve the problems of alumina dispersion and dissolution, and achieve the effects of reducing the generation of precipitation, uniform distribution, and delaying the speed of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

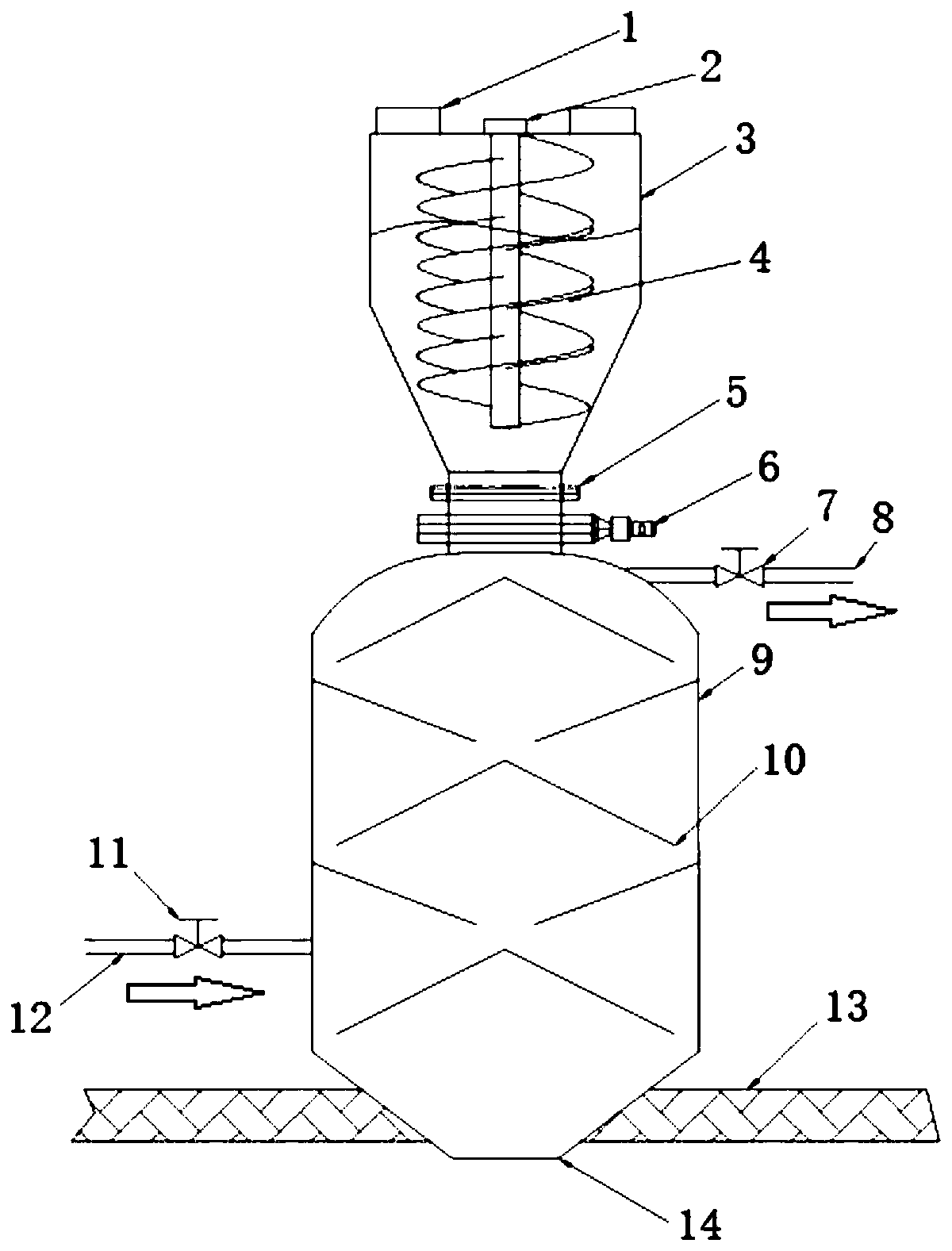

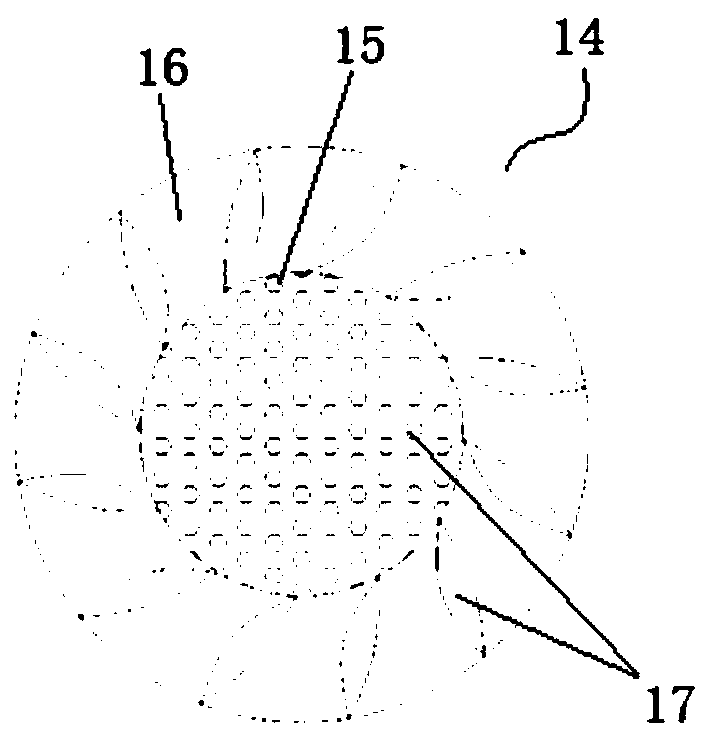

[0038] see figure 1 , the alumina blanking system in the illustration is a specific embodiment of the present invention, and specifically includes two parts: a pulverizer 3 and a feeder 9. The pulverizer 3 and the feeder 9 are vertically arranged up and down. The pulverizer 3 The bottom of the bottom and the top of the feeder 9 are butt-connected, wherein the feeding port 1 of the entire feeding system is located at the top of the pulverizer 3, the feeding port 14 is located at the bottom of the feeding device 9, and the entire feeding system is arranged in the electrolytic cell 13 Above, the feeding port 14 is set at the feeding position of the electrolytic cell 13 , and the alumina powder processed by the feeding system is added to the interior of the electrolytic cell 13 through the feeding port 14 .

[0039]Wherein, the interior of the pulverizer 3 is provided with a rotating guide rod 2, and the rotating guide rod 2 is mounted on the top of the pulverizer 3, and is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com