Automobile instrument panel and LED assembly integrated compression molding equipment and compression molding process thereof

A technology for LED components and car dashboards, applied in dashboards, vehicle parts, transportation and packaging, etc., can solve problems such as damage to finished products, inconvenience in compression molding, and inconvenience in demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

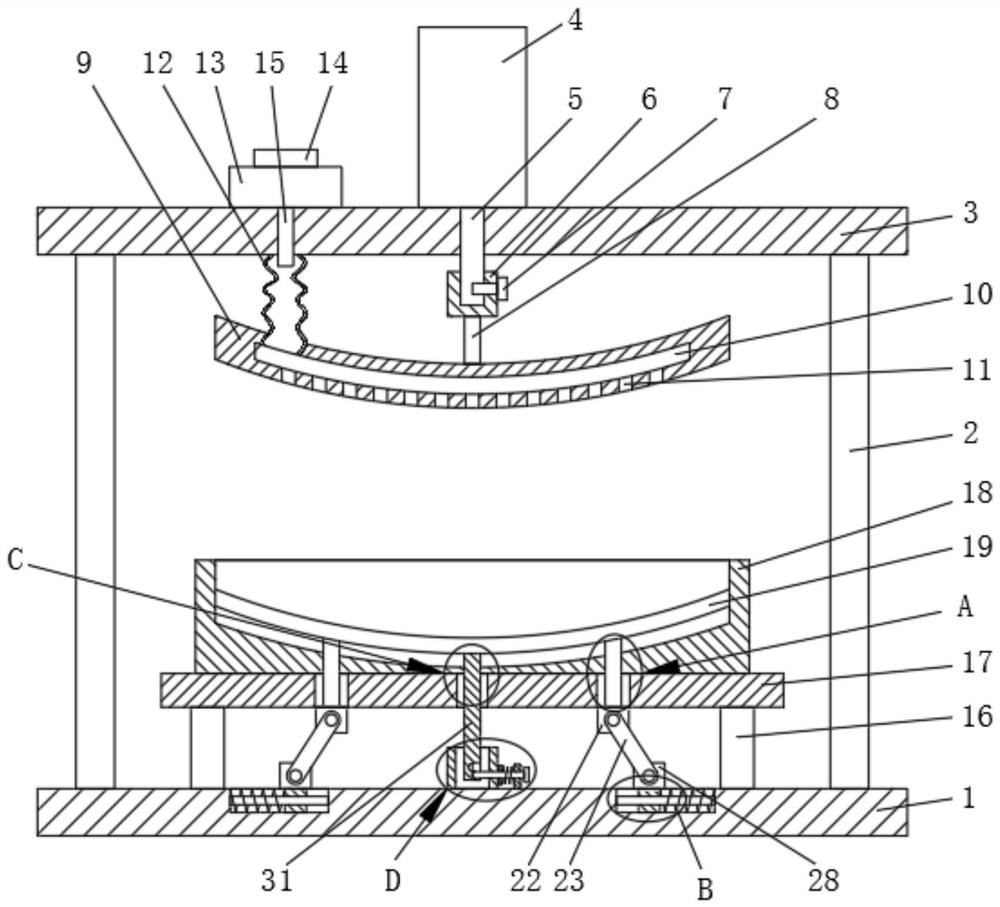

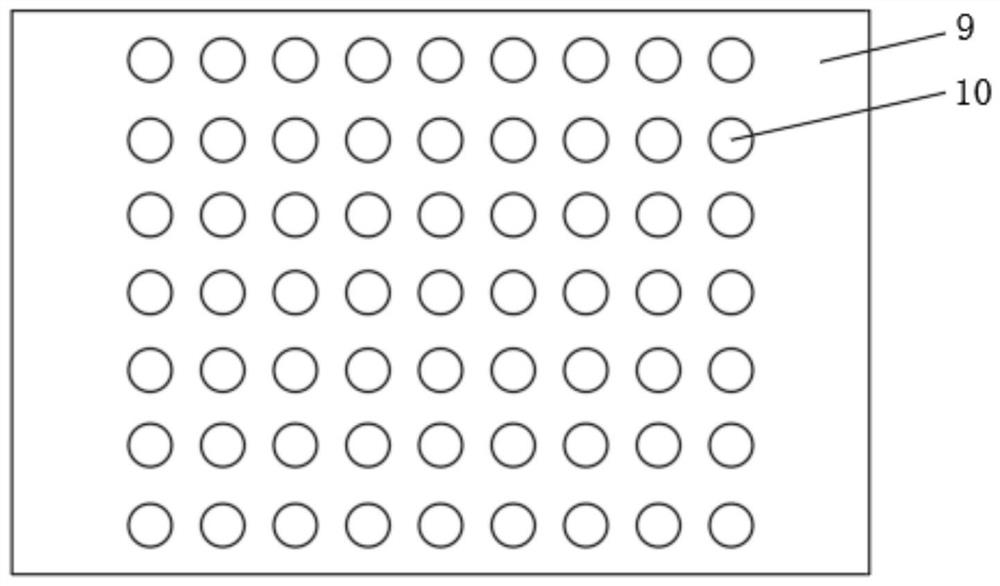

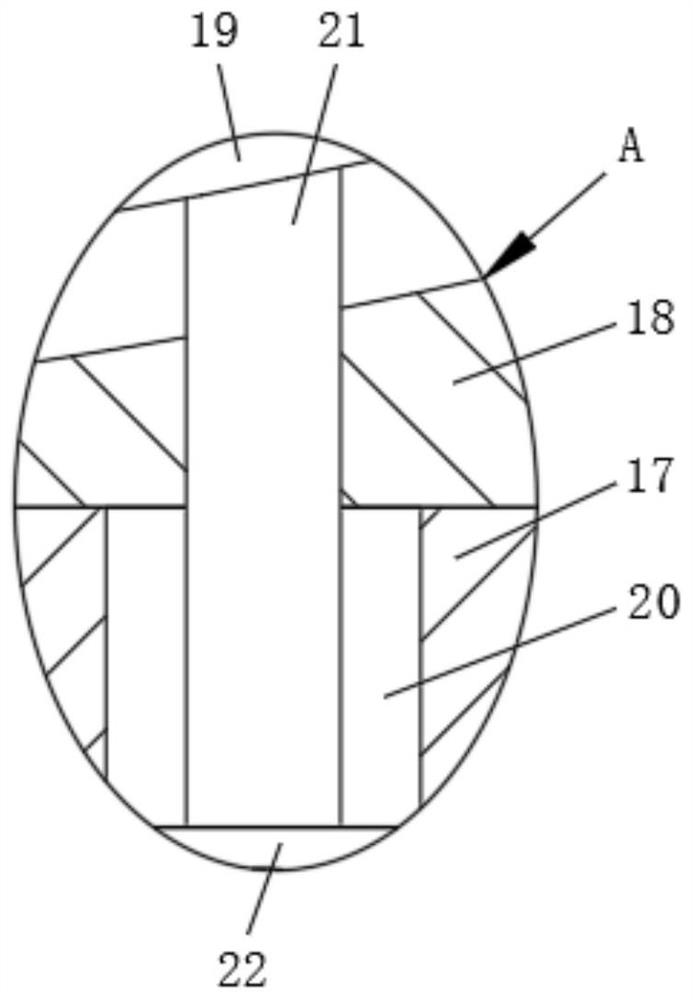

[0031] An automobile instrument panel and LED component integrated compression molding equipment, comprising a bottom plate 1 and a workbench 17, the upper end of the bottom plate 1 is fixedly connected with four evenly distributed support rods 2, and the upper end of the support rod 2 is fixedly connected with a support Plate 3, the support plate 3 is provided with a cylinder 4, the drive rod 5 of the cylinder 4 is slidingly connected with the support plate 3, the outside of the drive rod 5 is sleeved with a connecting seat 6, and the inside of the connecting seat 6 The limit screw 7 is threadedly connected, the tail end of the limit screw 7 is clamped with the drive rod 5, the lower end of the connecting seat 6 is fixedly connected with a connecting rod 8, and the lower end of the connecting rod 8 is fixedly connected with an upper die 9. An air duct 10 is opened inside the upper mold 9 , and an air outlet 11 is opened inside the upper mold 9 , and the air outlet 11 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com