Physical simulation experiment device, system and method for SAGD technology

A technology of physical simulation and experimental device, applied in teaching model, earthwork drilling, mining fluid, etc., can solve the problems of long preheating time, easy blockage, difficult to accurately measure the vertical relative permeability curve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

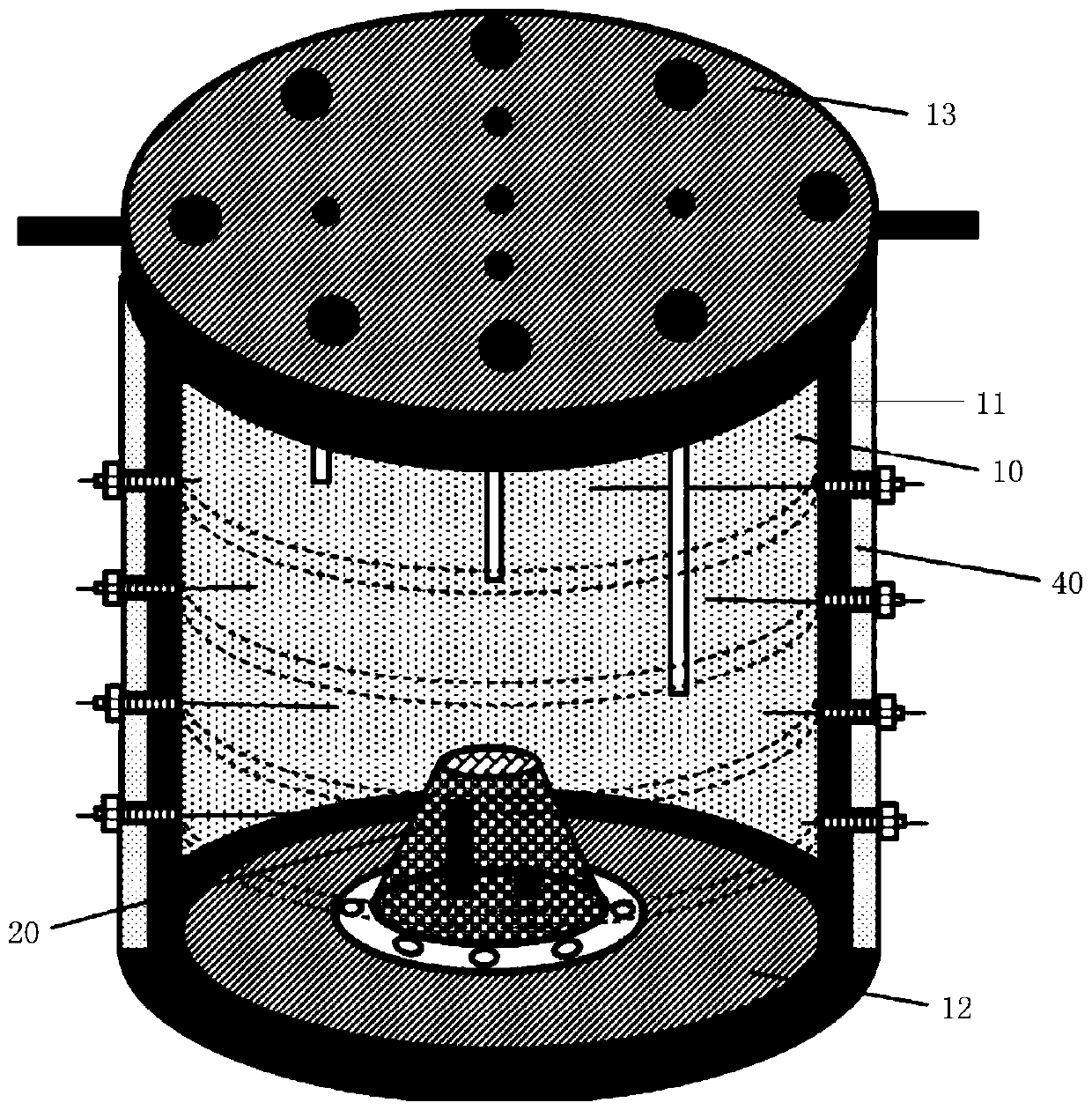

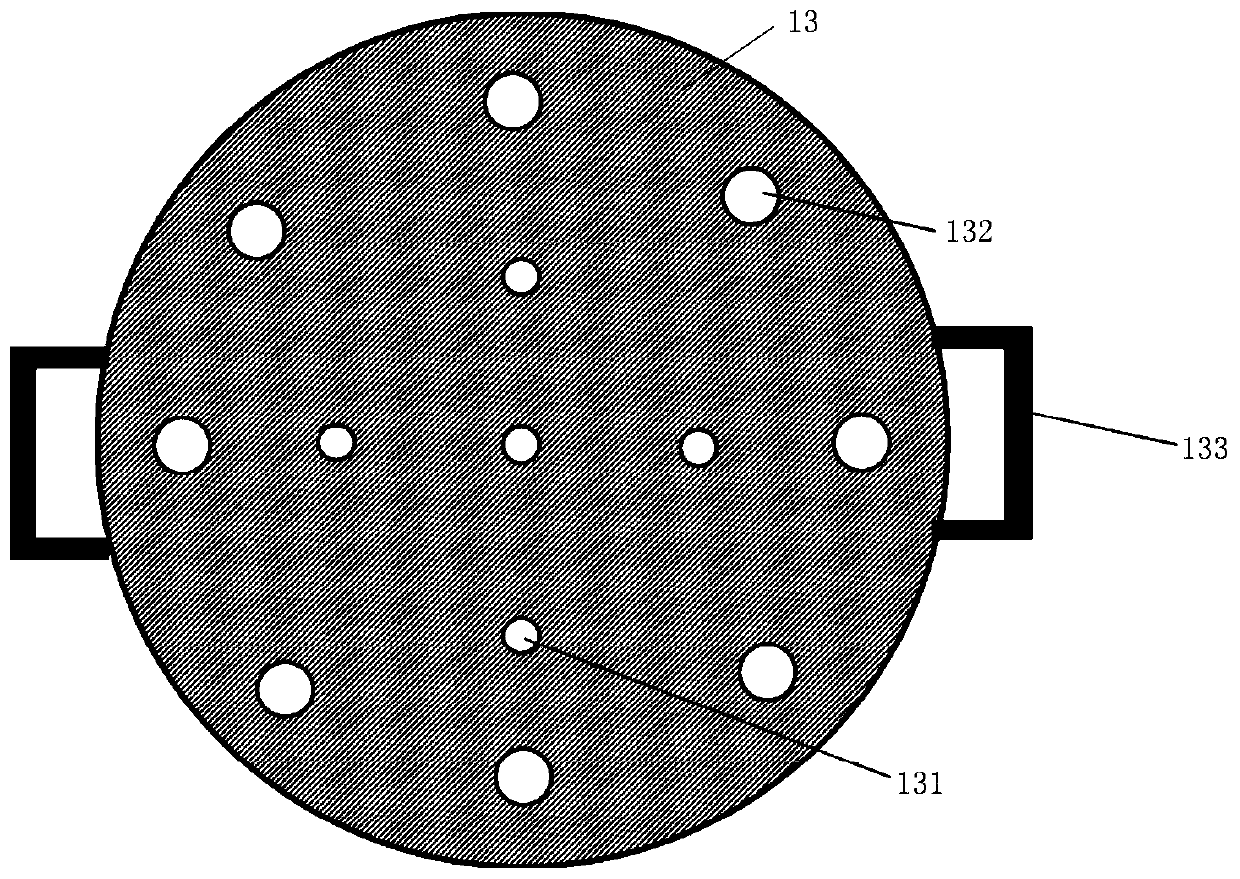

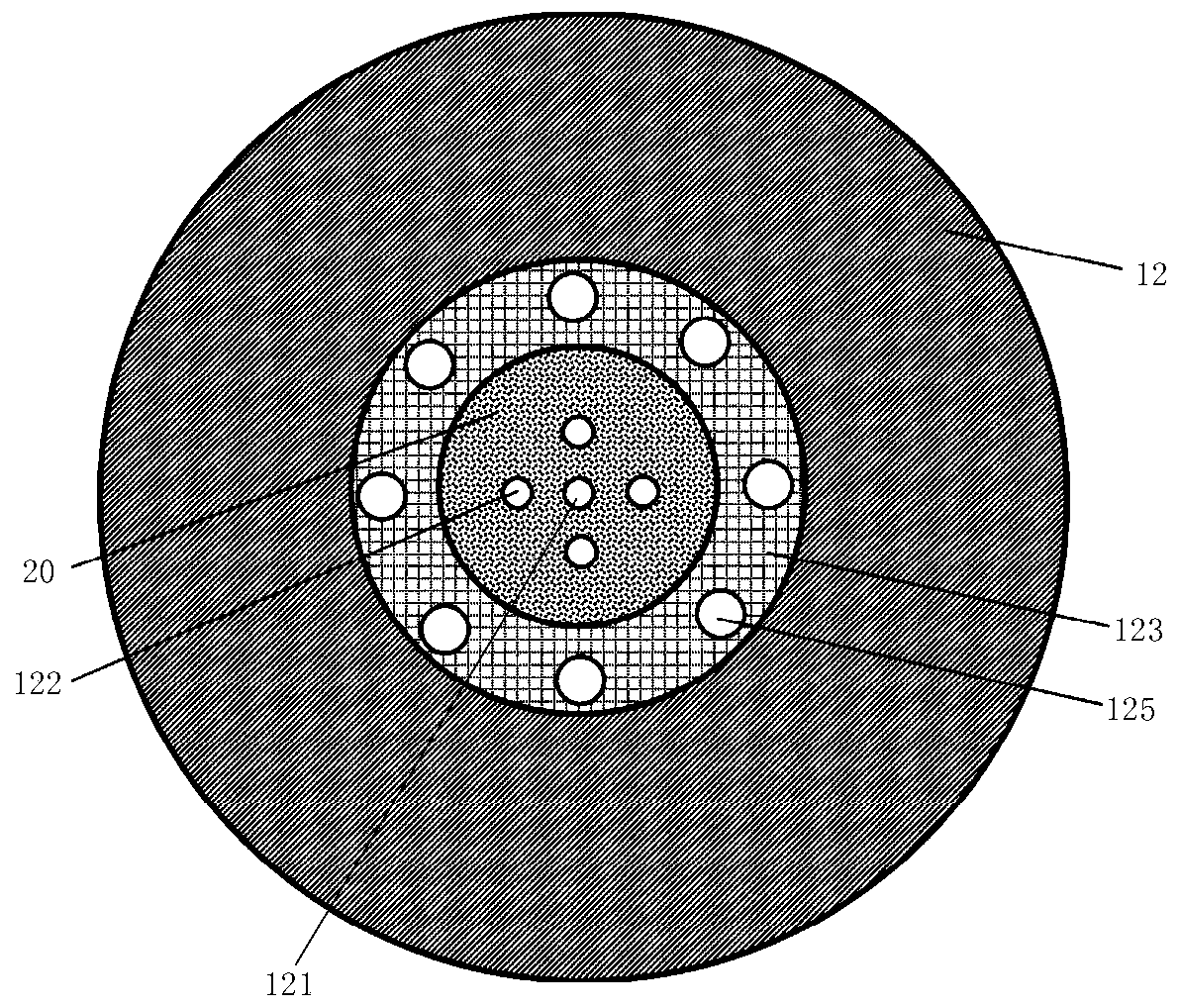

[0076] The invention provides a physical simulation experiment device of SAGD technology, such as figure 1 and Figure 5a As shown, the physical simulation experimental device includes: a model cylinder 10, a preheating cylinder 20, a simulated production well 32 and a simulated steam injection well 31. The model cylinder 10 is filled with first particles 51 to construct the porous medium of the oil sand reservoir Environment; the preheating cylinder 20 is arranged at the bottom of the model cylinder 10, and the preheating cylinder 20 is filled with second particles 52, and the cylinder wall of the preheating cylinder 20 is provided with a hole structure 21 to communicate with the preheating cylinder 20 and the model cylinder 10 ; The simulated production well 32 and the simulated steam injection well 31 communicate with the preheating cylinder 20 respectively.

[0077] The physical simulation experiment device of the SAGD technology constructs the porous medium environment o...

Embodiment 2

[0098] The invention provides a physical simulation experiment system of SAGD technology, such as Figure 7 As shown, the physical simulation experiment system includes: a steam generator 61, a liquid extraction device 70 and the physical simulation experiment device of the above-mentioned SAGD technology; the steam generation device 61 is connected with the simulated steam injection well 31 in the physical simulation experiment device; The device 70 is connected with the simulated production well 32 in the physical simulation experiment device. The steam generating device 61 is used to inject steam into the simulated steam injection well 31 ; specifically, the steam generating device 61 includes a high-pressure constant-speed pump 611 and a steam generator 612 . The condensate entering the simulated production well 32 is collected and processed by the liquid collection device 70 ; specifically, the liquid collection device 70 includes a back pressure valve 702 , a hand pump 7...

Embodiment 3

[0103] The present invention provides a kind of physical simulation experimental method of SAGD technology, adopt the physical simulation experimental device of above-mentioned SAGD technology, such as Figure 11 As shown, the physical simulation experiment method includes:

[0104] Step S100, filling the model cylinder with first particles, and filling the preheating cylinder with second particles;

[0105] Step S200, open the simulated steam injection well 31 and the simulated production well 32, and inject steam into the simulated steam injection well 31 at the first steam injection rate for preheating;

[0106] Step S300 , inject steam into the simulated steam injection well 31 at a second steam injection rate, and extract liquid through the simulated production well 32 .

[0107] This physical simulation experiment method can be applied to the oil sand SAGD method. After the physical simulation experiment device and supporting equipment are assembled, it first enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com