Heat-recovery air flue system used for kiln

A heat recovery and air duct technology, used in furnaces, waste heat treatment, furnace components, etc., can solve the problems of inability to guarantee the quality of ceramic tiles, energy waste, and difficulty in reusing the heat of roller kilns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

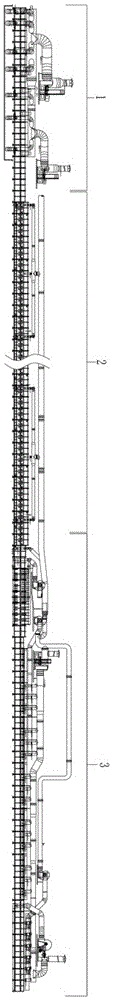

[0019] In this embodiment, a heat recovery air duct system for a kiln is provided with a preheating zone 1 , a firing zone 2 and a cooling zone 3 in sequence along the production direction of the kiln.

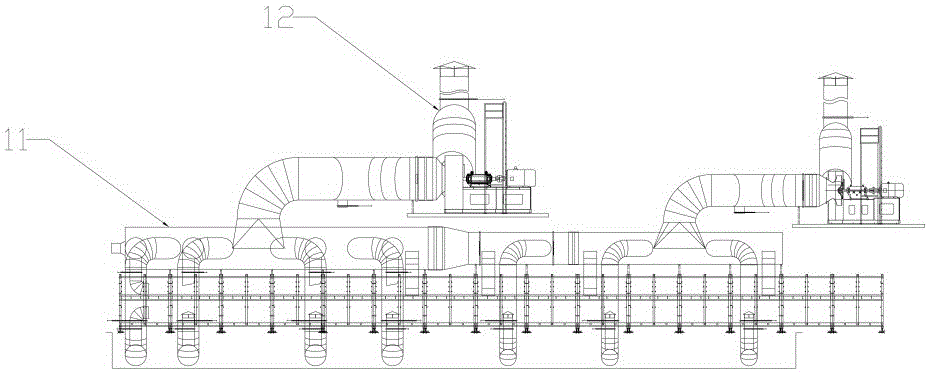

[0020] In this embodiment, the preheating zone 1 includes a smoke main pipe 11 and a two-stage smoke exhaust fan 12, and the smoke main pipe 11 is connected with the preheating zone 1 kiln and the two-stage smoke exhaust fan 12 respectively, wherein the smoke main pipe 11 is connected with the kiln road A plurality of smoking branch pipes are arranged to connect with each other. Through the above method, use the two-stage exhaust fan 12 to smoke the kiln, draw the smoke with heat generated in the firing zone 2 to the preheating zone 1 for preheating treatment, and at the same time discharge the smoke out of the kiln through the exhaust fan middle.

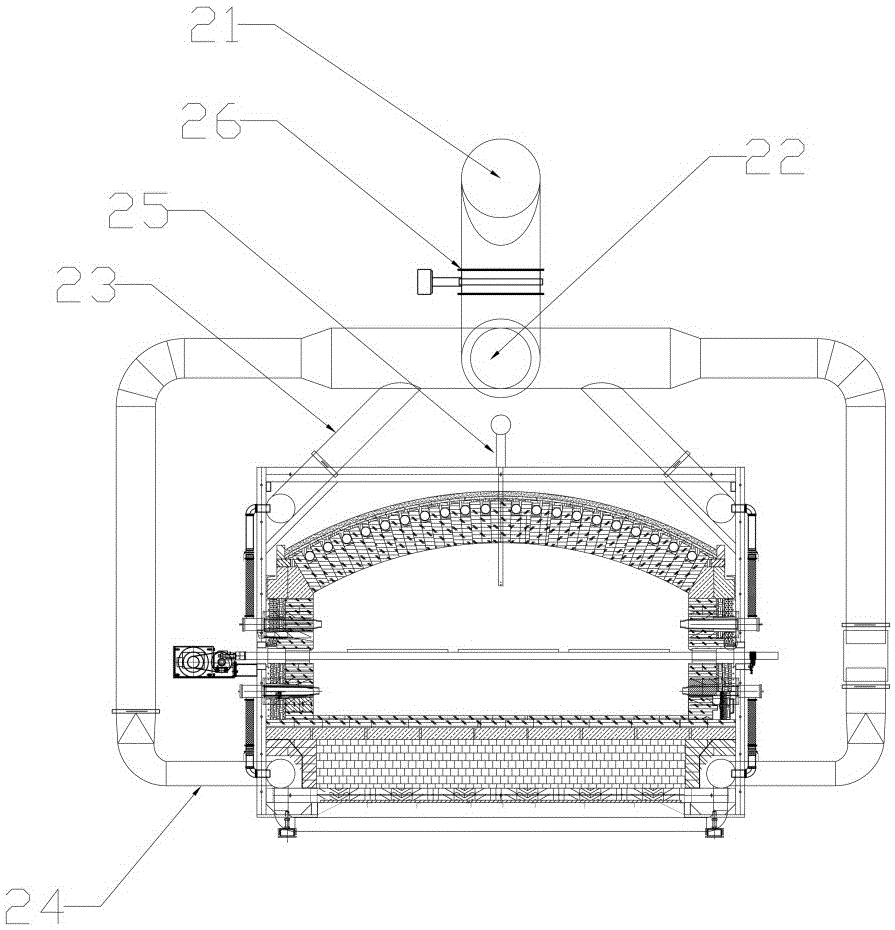

[0021] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com