Refrigerant circuit

a refrigerant circuit and circuit technology, applied in the field of refrigerant circuits for vehicles, can solve the problems of reducing the efficiency of the compressor, the pump contains an excessive amount of refrigerant, etc., and achieves the reduction of the amount of filling, the effect of minimizing the cross-section of the conduit and reducing the cost and a weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

of EXEMPLARY EMBODIMENTS OF THE INVENTION

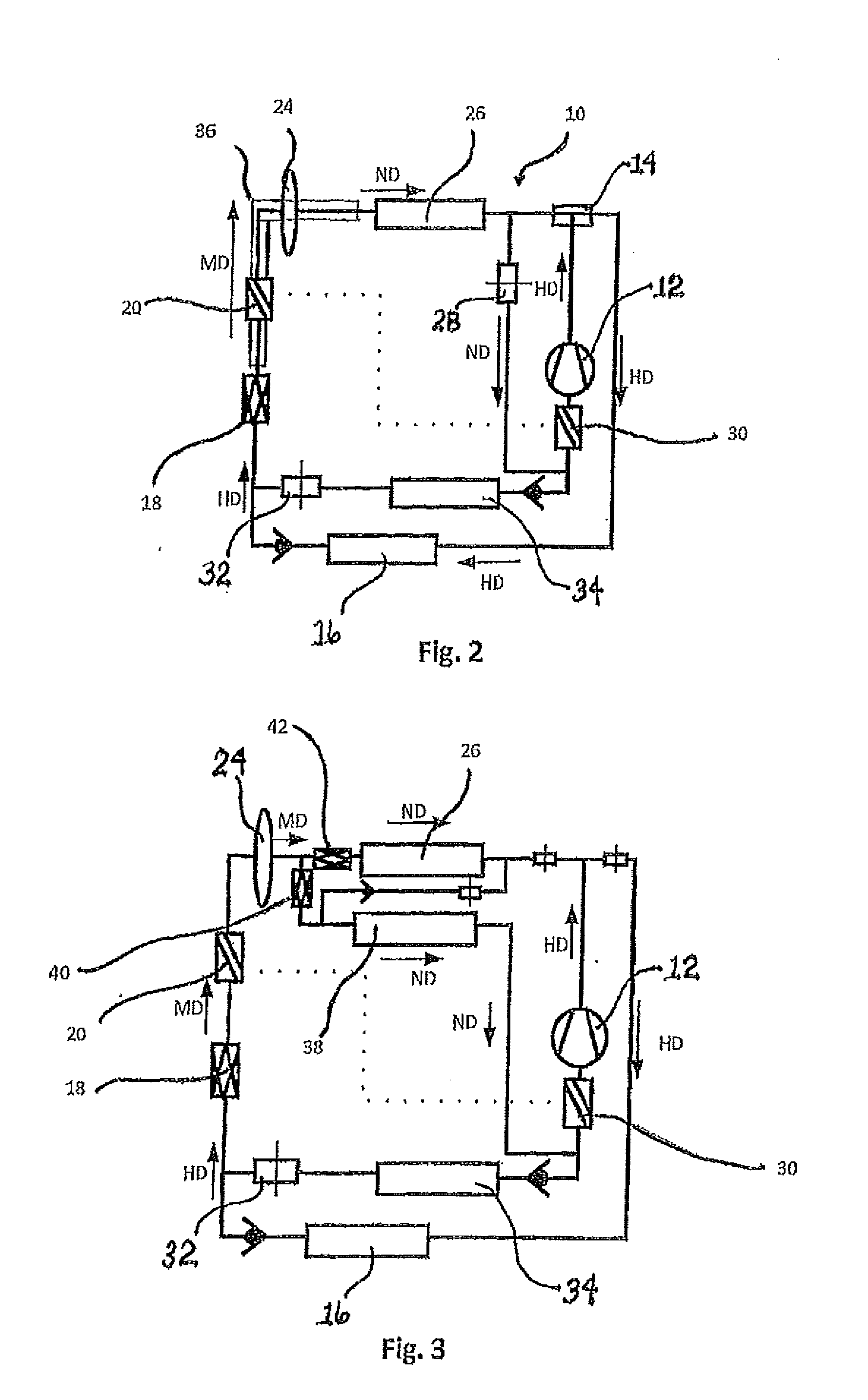

[0037]The following detailed description and appended drawings describe and illustrate various exemplary embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner. Equivalent components or components with equivalent effect are shown in the following examples of embodiments with the same reference list number.

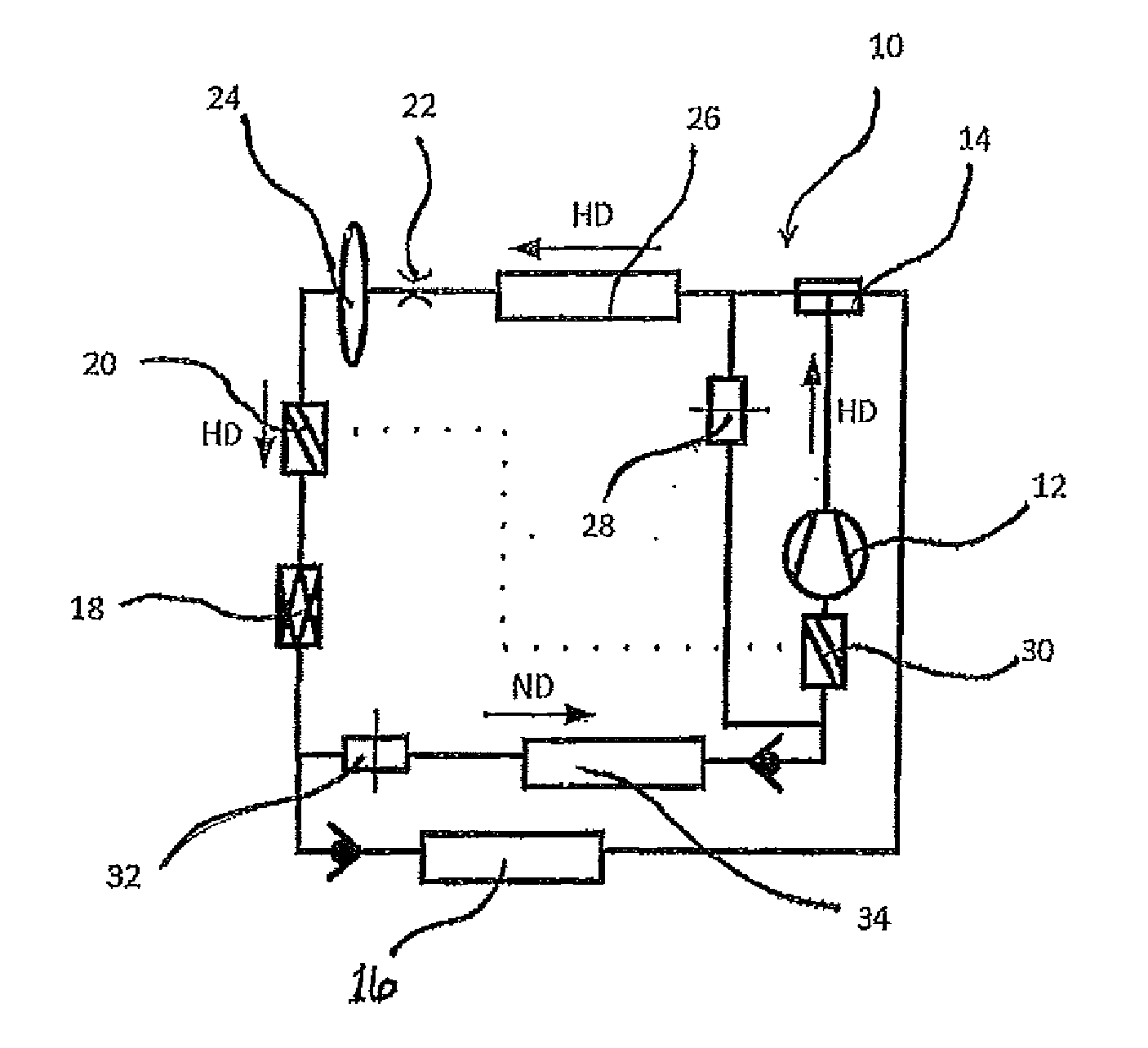

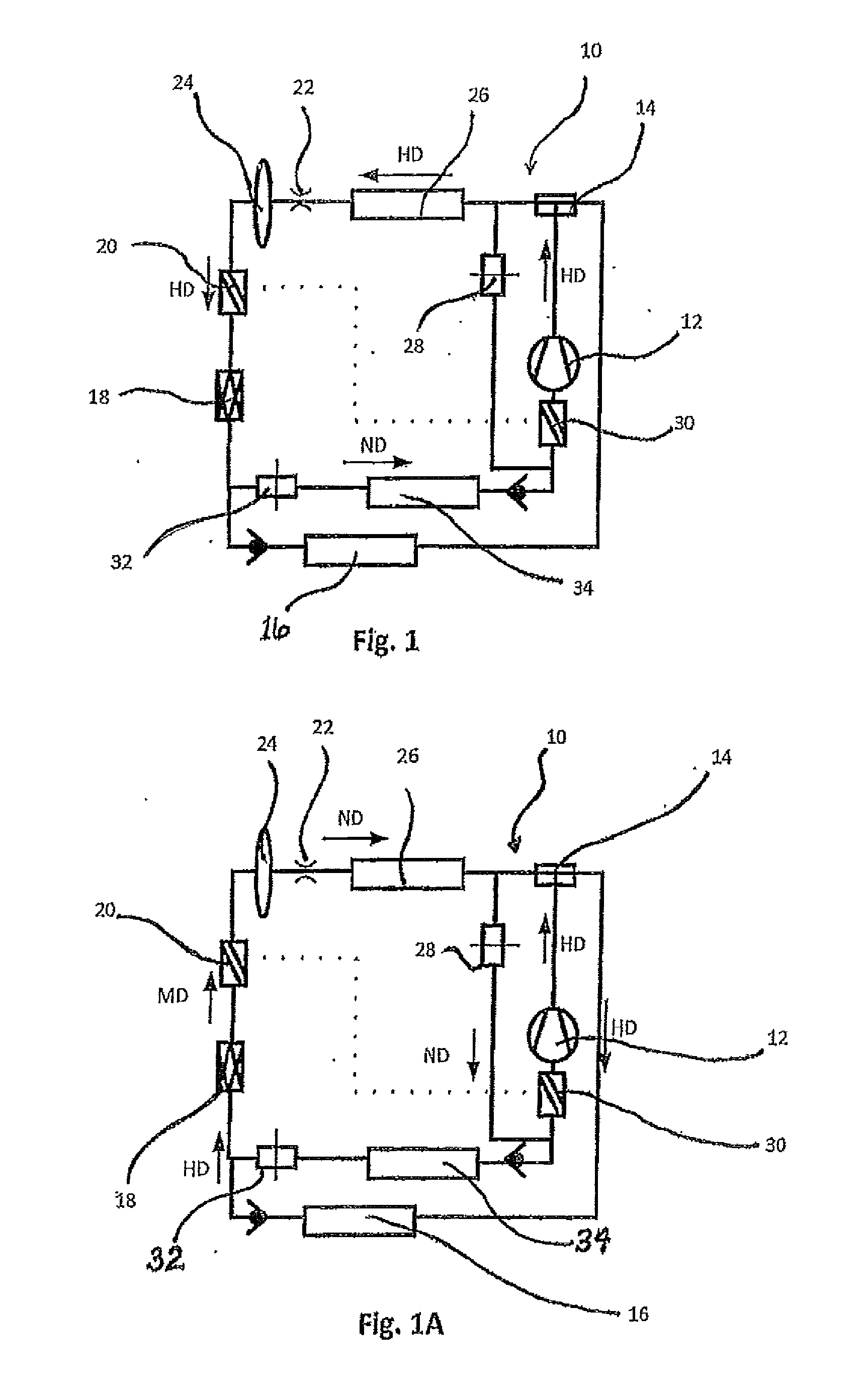

[0038]FIGS. 1 and IA show a schematic presentation of a refrigerant circuit 10 of a vehicle air conditioner according to the present invention. The refrigerant circuit 10 is suitable for both a cooling operation, illustrated in FIG. 1, and a heat pump operation, illustrated in FIG. 1A. During the cooling operation shown in FIG. 1, a refrigerant under high pressure flows out of a compressor 12 through a valve 14, through a condenser / gas cooler 26, and through a metering device 22. As a non-limiting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com