Novel process for producing manganese sulfate by combination of pyrogenic process and wet process

A manganese sulfate and new process technology, applied in manganese sulfate and other directions, can solve the problems of poor product quality indicators, high discharge of manganese sludge, low selling price, etc., and achieve the effects of good fluidity, good stability and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A new process for producing manganese sulfate by fire method combined with wet method, the steps are as follows:

[0037] (1) Roasting reduced manganese powder: The raw material pyrolusite and anthracite powder are roasted at a weight ratio of 1:0.14, the roasting temperature is 850°C, and the roasting time is 6 hours to obtain roasted manganese powder, namely reduced manganese powder.

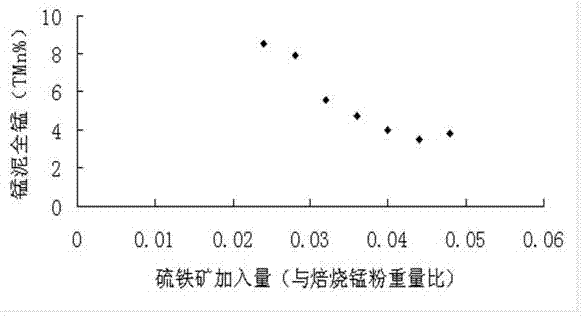

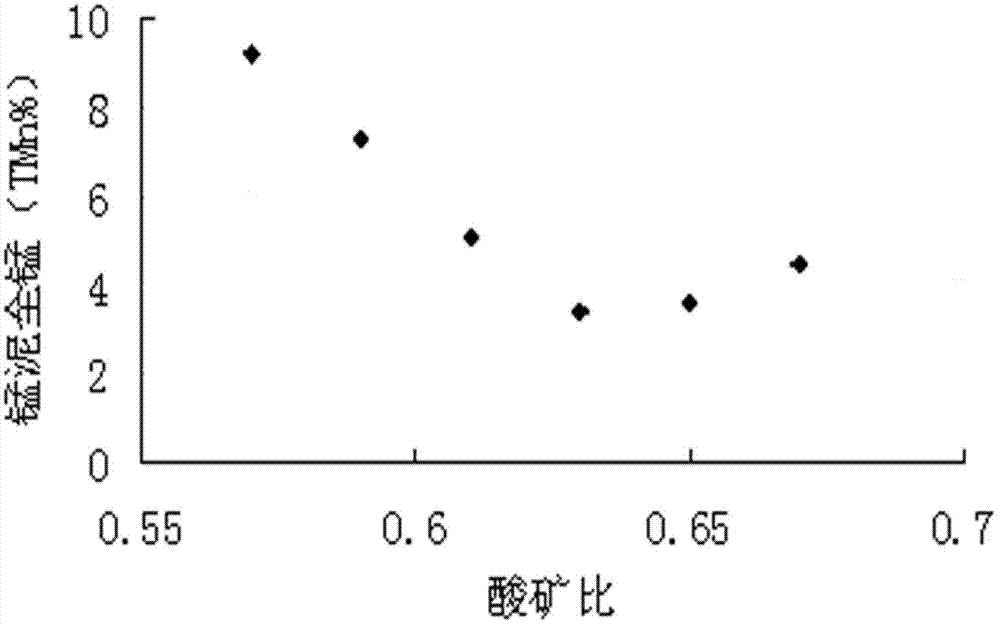

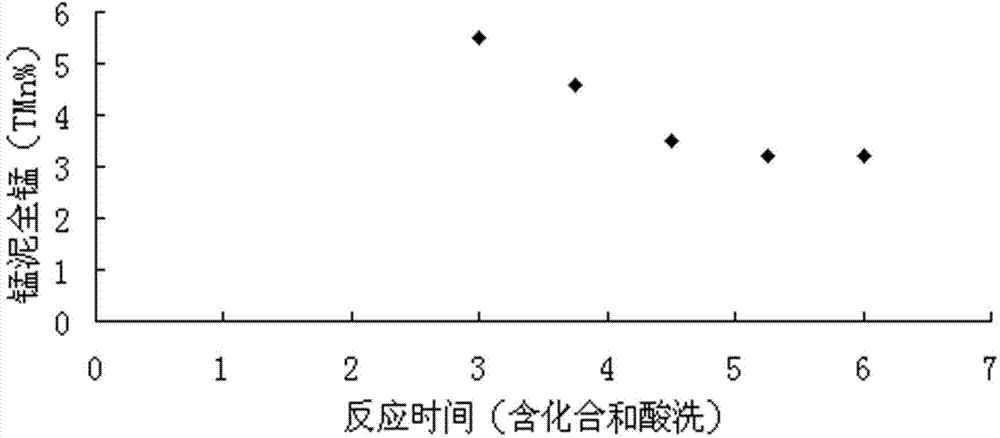

[0038] (2) Compound leaching: the secondary liquid and reduced manganese powder are mixed at a weight ratio of 2.8:1 to make a slurry, then 98% industrial sulfuric acid is added for chemical leaching, and pyrite is added to assist leaching. The amount of pyrite is roasted manganese powder 0.04 times the weight; heat the slurry at 92°C, react for 3 hours, and filter to obtain the primary slag and primary liquid after the reaction.

[0039] (3) Add pickling slag: the primary slag is mixed with water and tertiary liquid to make a slurry with a concentration of 23 degrees Baume, add 98% ind...

Embodiment 2

[0043] A new process for producing manganese sulfate by fire method combined with wet method, the steps are as follows:

[0044] (1) Roasting reduced manganese powder: The raw material pyrolusite and anthracite powder are roasted at a weight ratio of 1:0.15, the roasting temperature is 820°C, and the roasting time is 5 hours to obtain roasted manganese powder, namely reduced manganese powder.

[0045](2) Compound leaching: the secondary liquid and reduced manganese powder are mixed at a weight ratio of 3:1 to make a slurry, then 98% industrial sulfuric acid is added for compound leaching, and pyrite is added to assist leaching. The amount of pyrite is roasted manganese powder 0.03 times the weight; heat the slurry at 88°C, react for 3.5 hours, and filter to obtain the primary slag and primary liquid after the reaction.

[0046] (3) Add pickling slag: the primary slag is mixed with water and tertiary liquid to make a slurry with a concentration of 25 degrees Baume, add 98% indu...

Embodiment 3

[0050] A new process for producing manganese sulfate by fire method combined with wet method, the steps are as follows:

[0051] (1) Reduced manganese powder: The raw material pyrolusite and anthracite powder are roasted at a weight ratio of 1:0.16, the roasting temperature is 800°C, and the roasting time is 4.5 hours to obtain roasted manganese powder, namely reduced manganese powder.

[0052] (2) Compound leaching: the secondary liquid and reduced manganese powder are mixed at a weight ratio of 3.2:1 to make a slurry, then 98% industrial sulfuric acid is added for compound leaching, and pyrite is added to assist leaching. The amount of pyrite is the weight of roasted manganese powder 0.025 times of that, heat the slurry at 93°C, react for 4 hours, and obtain primary slag and primary liquid by filtration after the reaction.

[0053] (3) Add pickling slag: the primary slag is mixed with water and tertiary liquid to make a slurry with a concentration of 26 degrees Baume, add 98...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com