Flexible production line for medium and large vehicle air conditioners

A production line and automobile air-conditioning technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of heavy weight, long time for invalid handling, and unstable quality, so as to achieve stable product quality and improve production efficiency , The clear effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

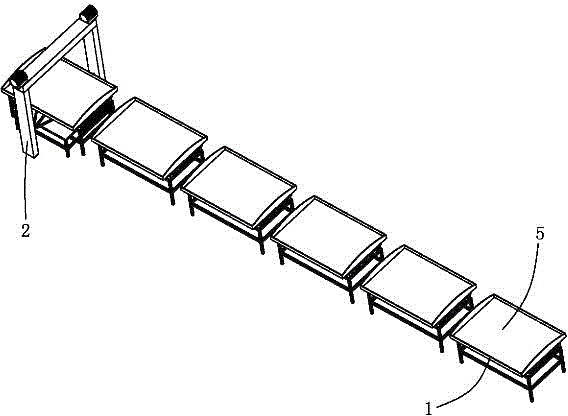

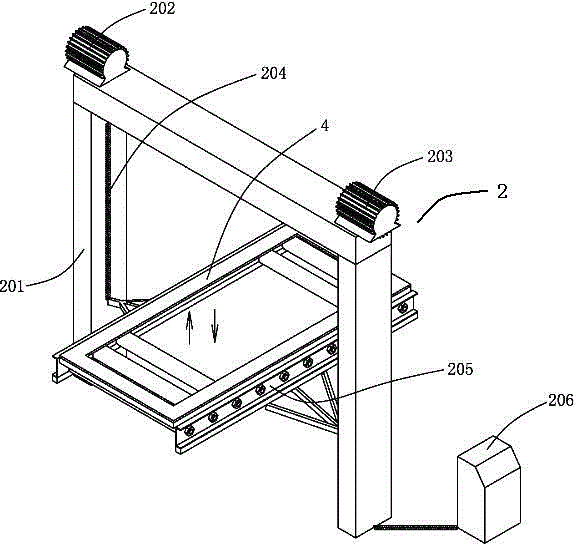

[0031] See attached figure 1 . A flexible production line for large and medium-sized automobile air conditioners. Under the condition that the site is not limited, corresponding unpowered roller workbenches 1 are set according to the needs of the production process to form a production line, that is, each unpowered roller workbench 1 represents In one process, a lifting platform 2 is set at the end of the production line, and a transition plate 4 is set on each unpowered roller table 1, and the transition plate 4 can slide on each unpowered roller table 1. Place large and medium-sized automotive air-conditioning components 5 on the plate 4 for installation.

[0032] The specific structure is set as:

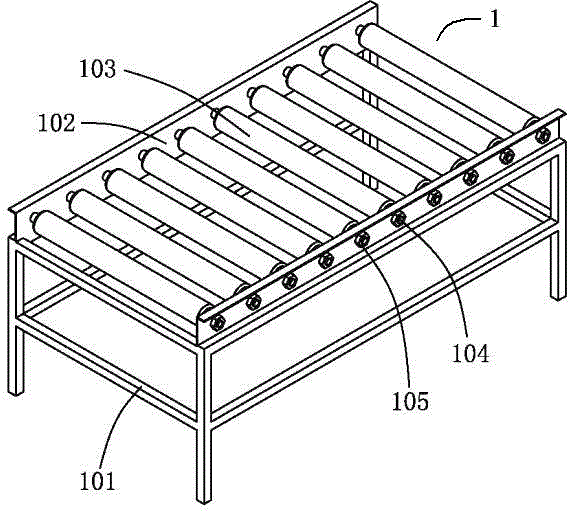

[0033] See attached figure 2 . The unpowered roller workbench 1 includes a base 101 made of metal structural parts (or cast iron), left and right brackets 102 of metal structure arranged above the base 101 , and unpowered rollers 103 are sleeved on the left and right bracket...

Embodiment 2

[0037] See attached figure 1 . A flexible production line for large and medium-sized automobile air conditioners. In the case of limited space, corresponding unpowered roller workbench 1 and rotating transition roller workbench 3 are set up according to the needs of the production process to form a production line. A rotating transition drum workbench 3 is set at every corner of the production line formed by two unpowered roller workbenches 1, so that the production line can be set to "L" shape or "U" shape to cope with the limitation of the site. Each unpowered roller table 1 and rotating transition roller table 3 represent a process. A lifting platform 2 is set at the end of the production line, and a transition piece is set on each unpowered roller table 1 and rotating transition roller table 3. Plate 4, the transition plate 4 can slide on each unpowered roller workbench 1 and the rotating transition roller workbench 3, and place large and medium-sized automotive air-condi...

Embodiment 3

[0041] A flexible production line for large and medium-sized automobile air conditioners. According to the needs of the production process, corresponding unpowered roller workbench 1 and rotating transitional roller workbench 3 are set to form a production line, that is, the unpowered roller workbench is set in the process that does not need to rotate Table 1, a rotating transition drum workbench 3 is set in the process that needs to be rotated, each unpowered roller workbench 1 and rotating transition drum workbench 3 represent a process; a lifting table 2 is set at the end of the production line, and in the A transition plate 4 is arranged on each unpowered roller workbench 1 and the rotating transition roller workbench 3, and the transition plate 4 can slide on each unpowered roller workbench 1 and the rotating transition roller workbench 3. Place large and medium-sized automotive air-conditioning components 5 on the plate 4 for installation.

[0042] The structure of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com