Medium-voltage hoisting cable for super high-rise building and production installation process thereof

A production process and construction technology, applied in the direction of power cable with shielding layer/conductive layer, insulated cable, cable/conductor manufacturing, etc., can solve the problems of difficult construction, increased cable cost, and increased cable material consumption, etc., to achieve The effect of improving hoisting safety margin, improving efficiency and safety, and improving hoisting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The above description is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention, it can be implemented according to the contents of the description, and in order to make the above and other purposes, features and advantages of the present invention more obvious and understandable , the specific embodiments of the present invention are enumerated below.

[0035] The invention provides one, for solving the prior art, in order to solve the above problems, the general idea of the present invention is as follows:

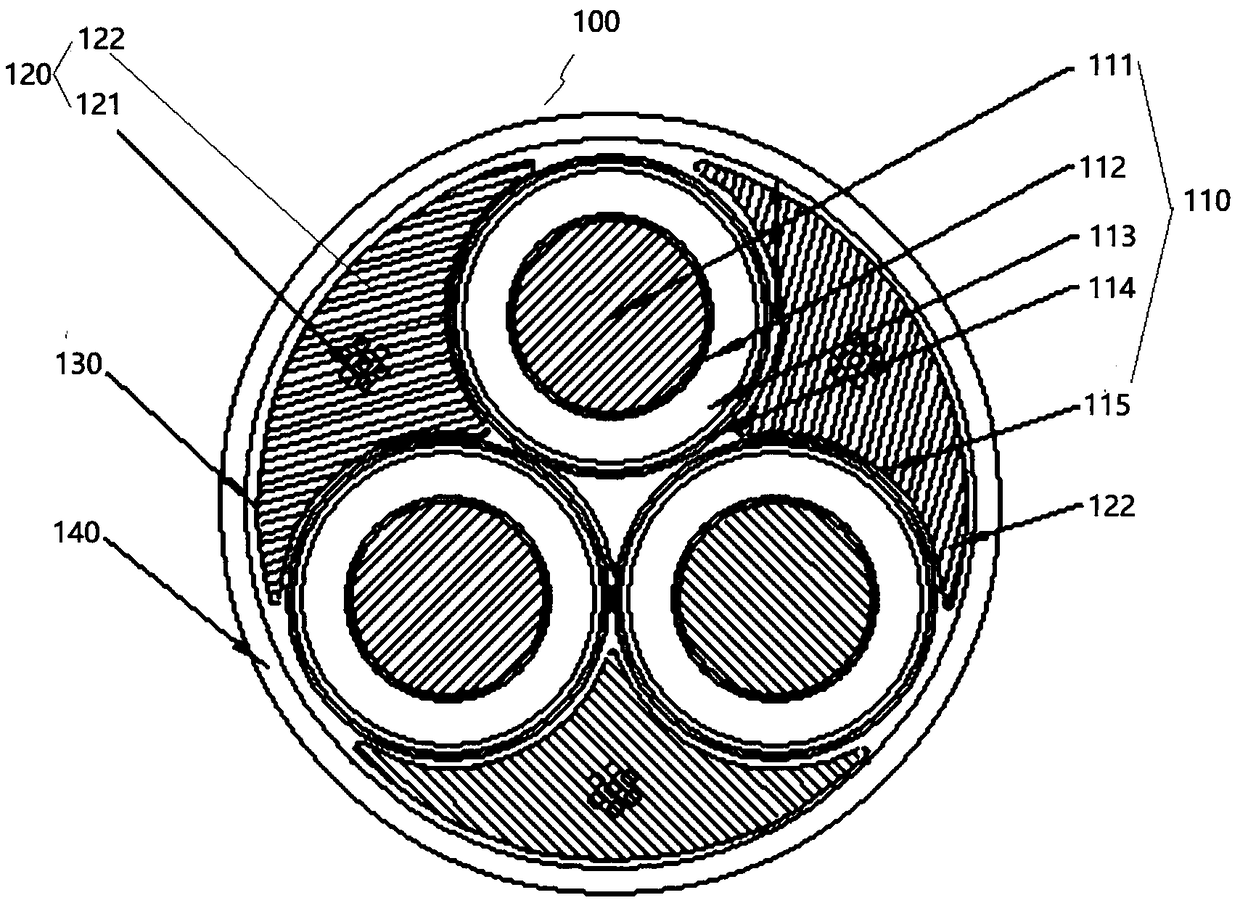

[0036] The medium-voltage hoisting cable 100 for super high-rise buildings includes an insulated core 110, a filling strip 120, a strengthening layer 130 and an outer sheath 140;

[0037] There are three insulated wire cores 110, which are tangent to each other, and the angle between the extension lines of the center of the adjacent insulated wire cores 110 is 120°;

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com