Multi-azimuth feed cutter bar manufacturing process capable of avoiding machining interference

A kind of manufacturing process and multi-faceted technology, applied in the direction of manufacturing tools, tool holder accessories, metal processing equipment, etc., can solve the problems of affecting tool life, high tool holder cost, high usage cost, saving tool holder materials, The effect of expanding the processing range and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

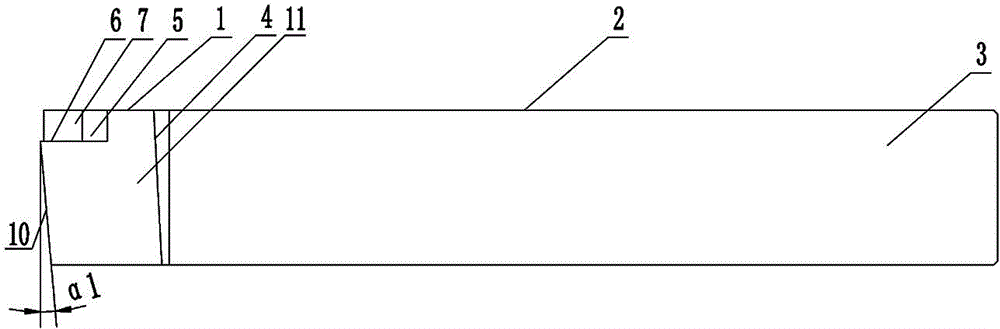

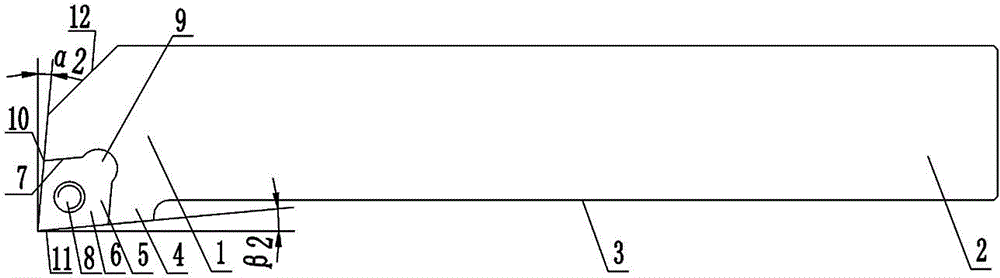

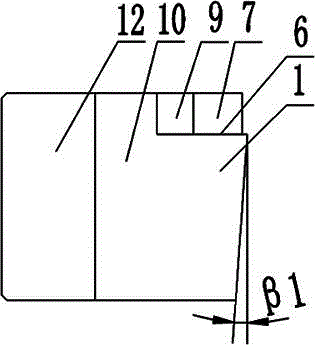

[0033] Such as figure 1 , figure 2 , image 3 As shown in the figure, a cutter bar that avoids machining interference and multi-directional cutting tool, the cutter bar includes a cutter head 1 and a square handle 2 connected in sequence, the cutter head 1 and the square handle 2 are an integral structure, the cutter head 1 is A boss 4 that exceeds the surface A3 of the square handle 2 is provided, and the cutter head 1 is placed on the left side of the handle 2, and the position of the surface A3 relative to the handle 2 is the front, and the upper surface of the cutter head 1 is located on the convex side. The left outer corner of the platform 4 side is provided with a blade groove 5, the blade groove 5 is diamond-shaped, the blade groove 5 is composed of a groove bottom surface 6 and two connected groove walls 7, and the groove bottom surface 6 is provided with a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com