Steel plate for container, and method for production thereof

A manufacturing method, a technology for steel sheets, applied in chemical instruments and methods, coating of superimposed layers, electrolytic inorganic material coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

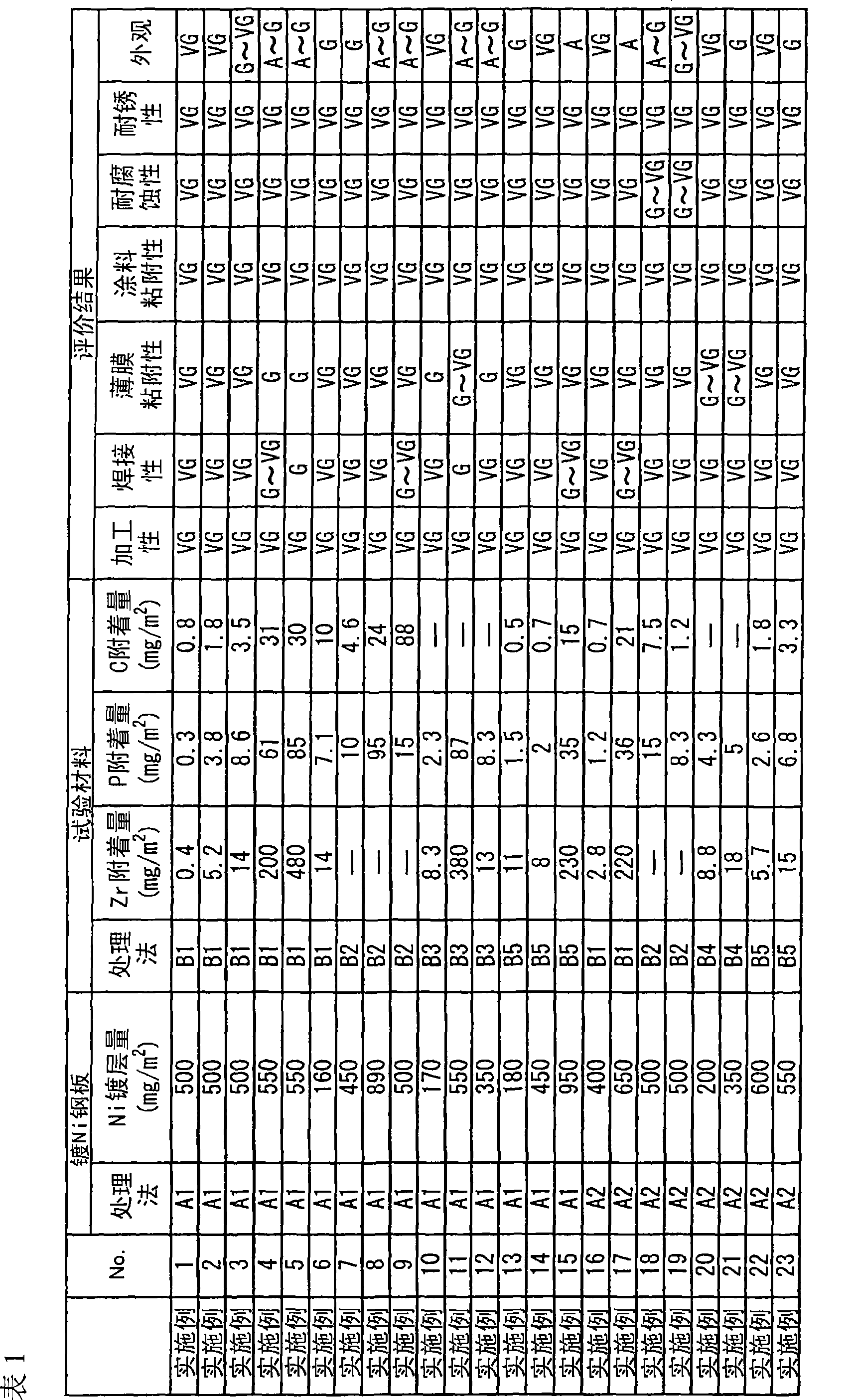

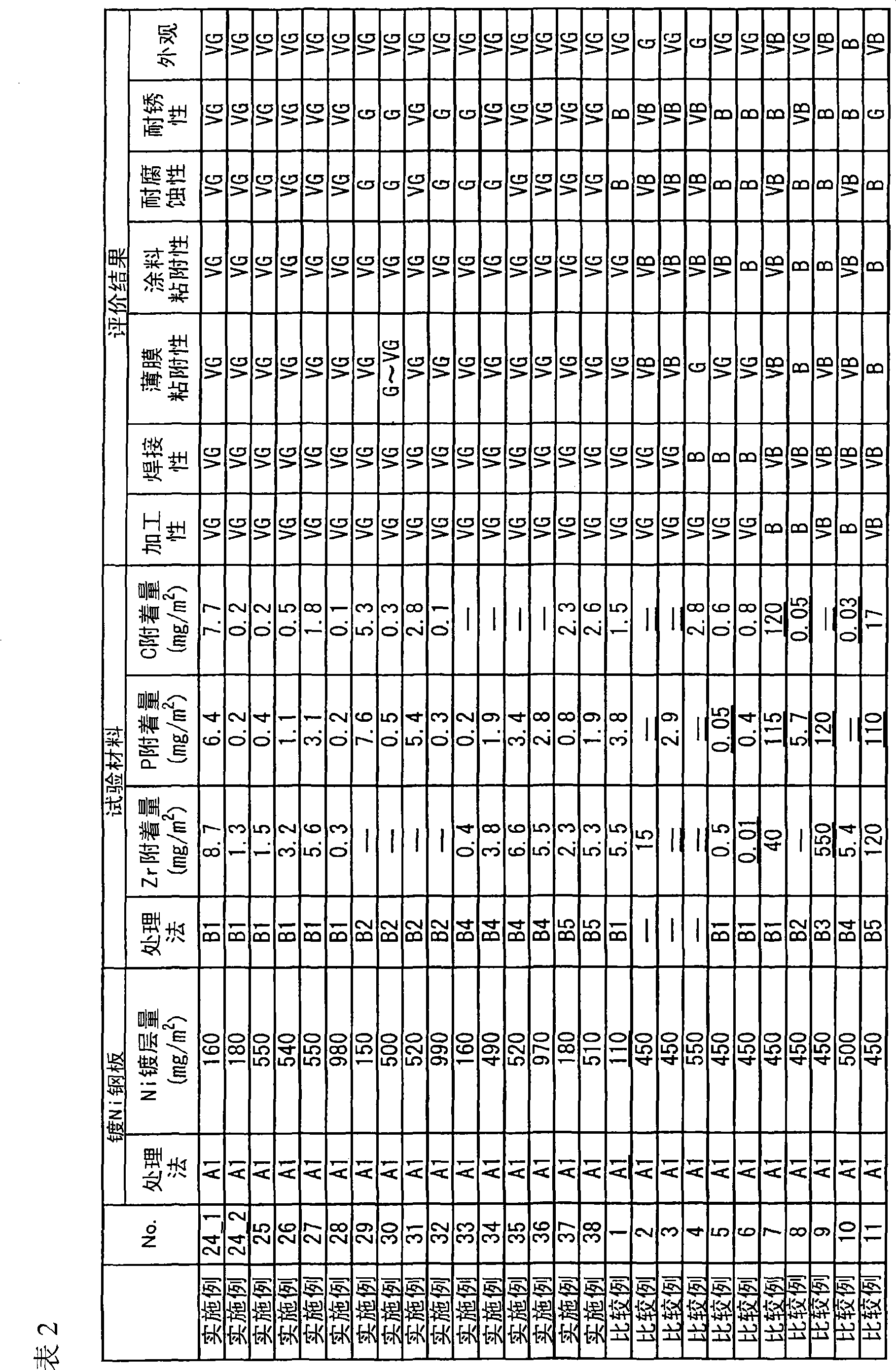

[0062] Hereinafter, the effects of the present invention will be specifically described with reference to Examples and Comparative Examples of the present invention. In this embodiment, first, (A1) after degreasing and pickling the steel base material (steel plate) with a thickness of 0.17 mm to 0.23 mm after cold rolling, annealing and pressure adjustment, a Watts bath is used on both surfaces thereof. Ni plating is performed, or (A2) Ni plating is performed on both sides of a cold-rolled steel substrate (steel plate) with a thickness of 0.17 mm to 0.23 mm using a Watt bath, followed by annealing to form a Ni diffusion layer, followed by degreasing and pickling , to produce a Ni-plated steel plate.

[0063] Next, a Zr film, a phosphoric acid film, and / or a phenolic resin film were formed on the surfaces (both sides) of the Ni-plated steel sheet produced by the above method (A1) or (A2) by the method shown below.

[0064] (B1) The Ni-plated steel sheet produced by the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com