Quaternary ammonium salts as a conversion coating or coating enhancement

a technology conversion coating, applied in the field of quaternary ammonium salt, can solve the problems of bare steel not forming a good bond with organic coating, danger of corrosion, etc., and achieve the effects of improving corrosion resistance, improving adhesion, and improving paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

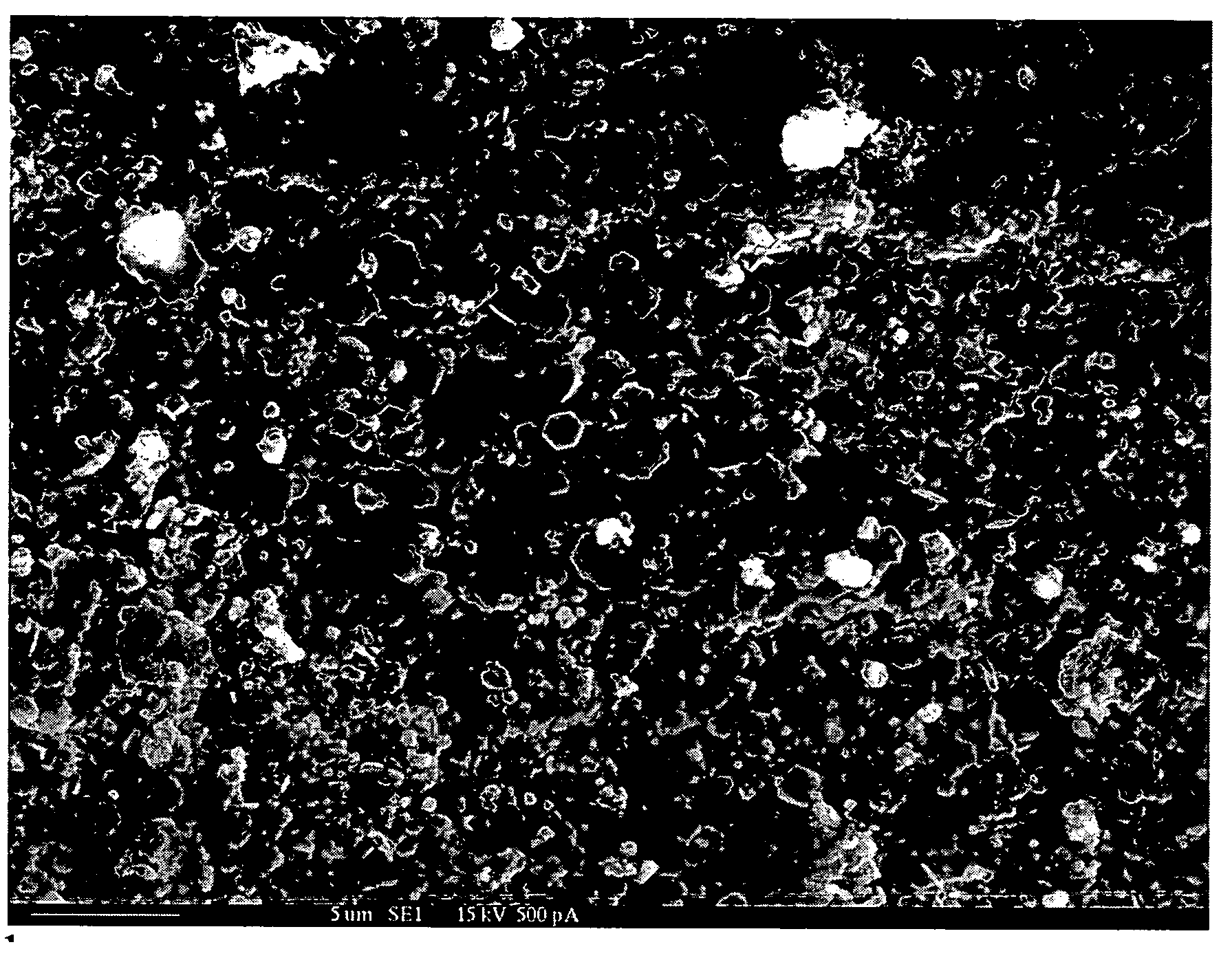

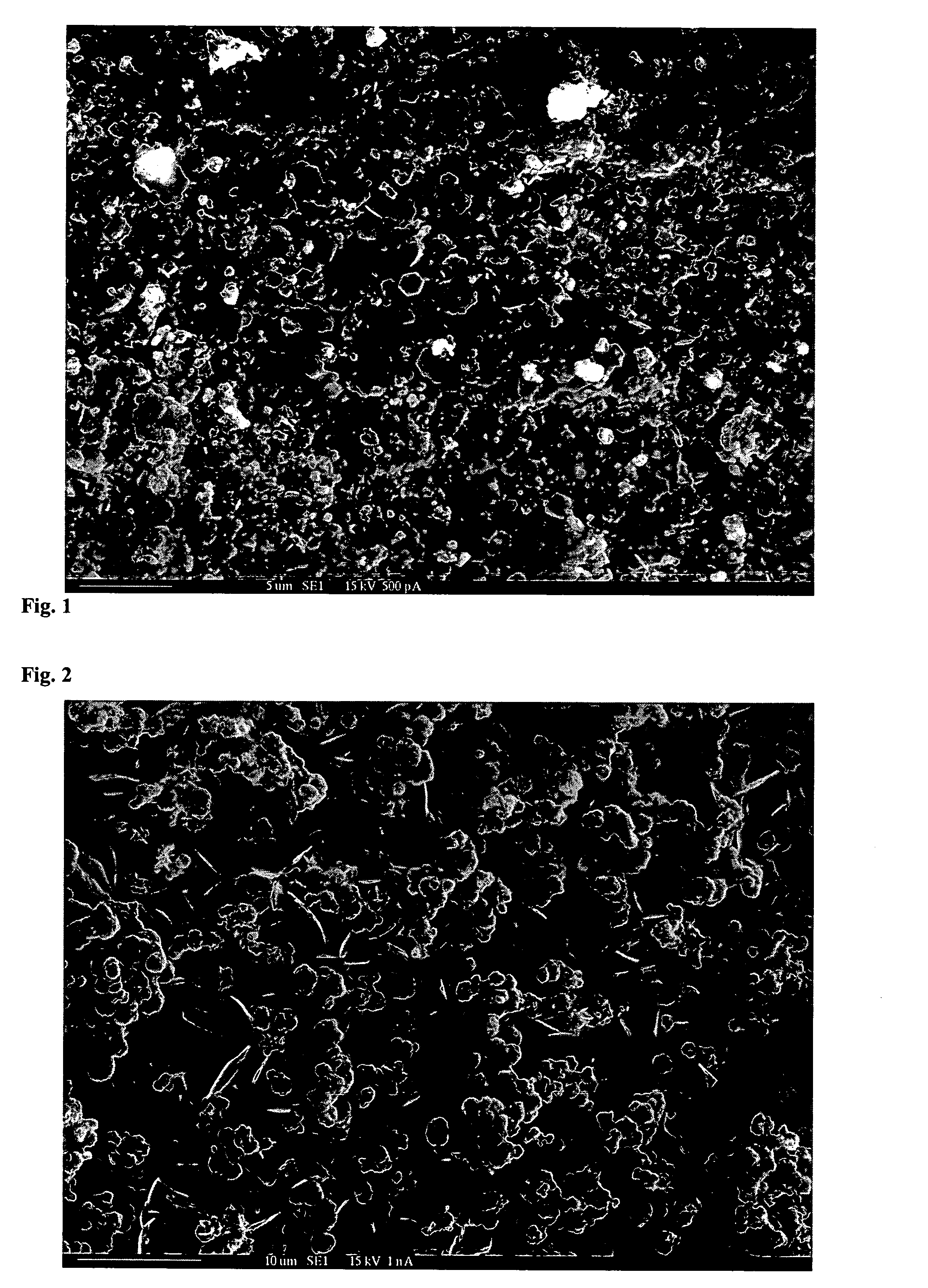

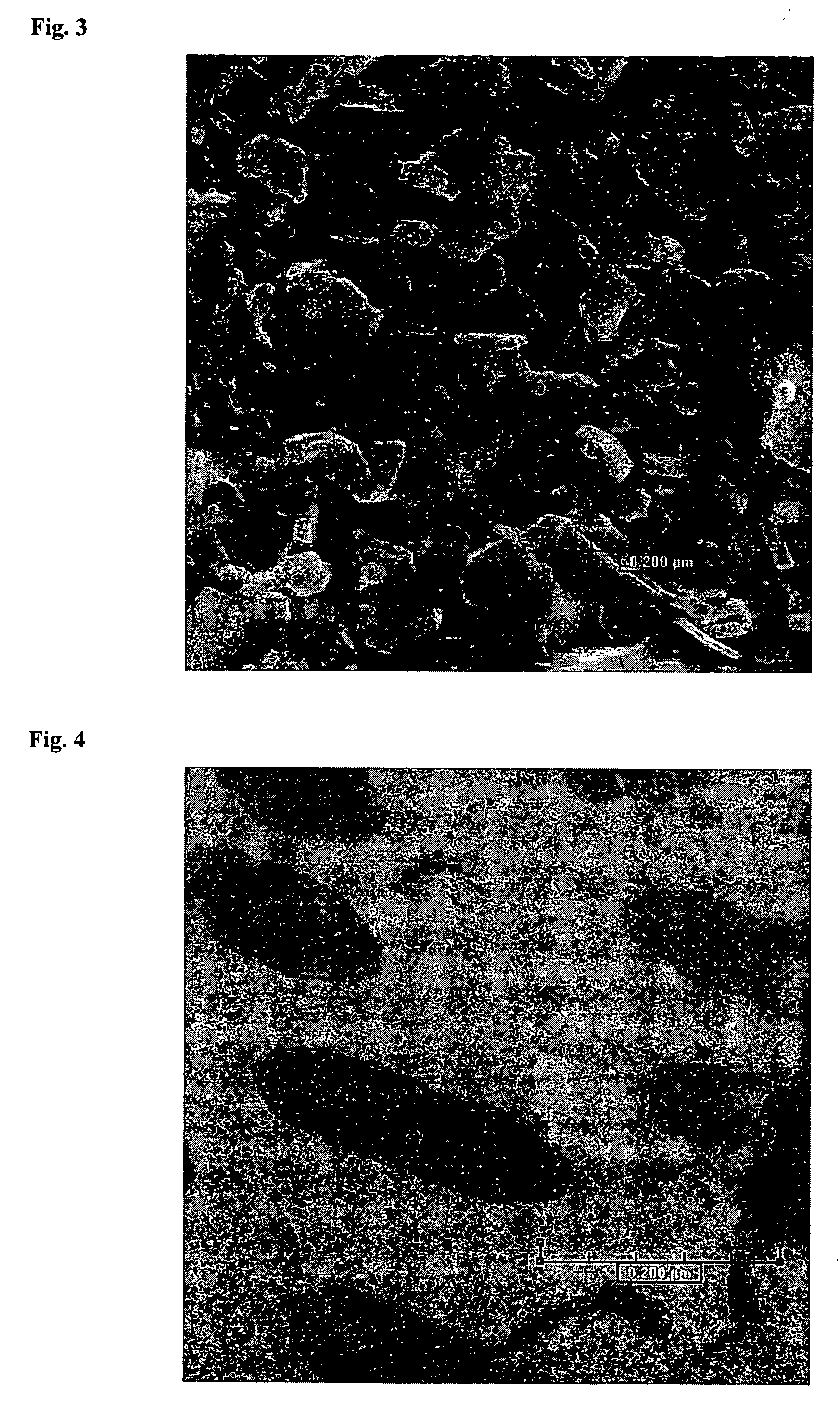

Image

Examples

example 1

[0057] A Conversion Coating Study (Reference: NB5751-001 through 018) was done with the objective to prepare steel panels (S-46, purchased from Q-Panel Lab Products, Cleveland, Ohio) with various aqueous treatments of either CarboShield® 1000 (di-n-decyldimethylammonium bicarbonate / carbonate), “Phosphoquat” (di-n-decyldimethylammonium phosphates), and various related controls.

[0058] A plastic tank being 27.9 cm (11″) in diameter and 27.9 cm (11″) in height was used to treat the panels. The plastic tank was filled with 9,600 grams of test solution. 10.16 cm×15.24 cm×1.59 mm (4″×6″× 1 / 16″) steel (S-46) panels with a hole of 6.35 mm (¼″) in diameter located 6.35 mm (¼″) from the top edge were treated by placing a plastic pipette through the hole in the panel. Up to three panels were skewed using the same pipette. This allowed for the panels to stand upright, with only the bottom of the panel touching the bottom of the tank. The tank was then placed in an oven which was at 70° C. for o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com