Allose tablet excipient, medicinal tablet and method for preparing medicinal tablet

A technology of allulose tablets and excipients, which is applied in the field of medicine, can solve the problems of high fragility and inability to be pressed into tablets, and achieve the effects of high hydrophilicity, good molding degree, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

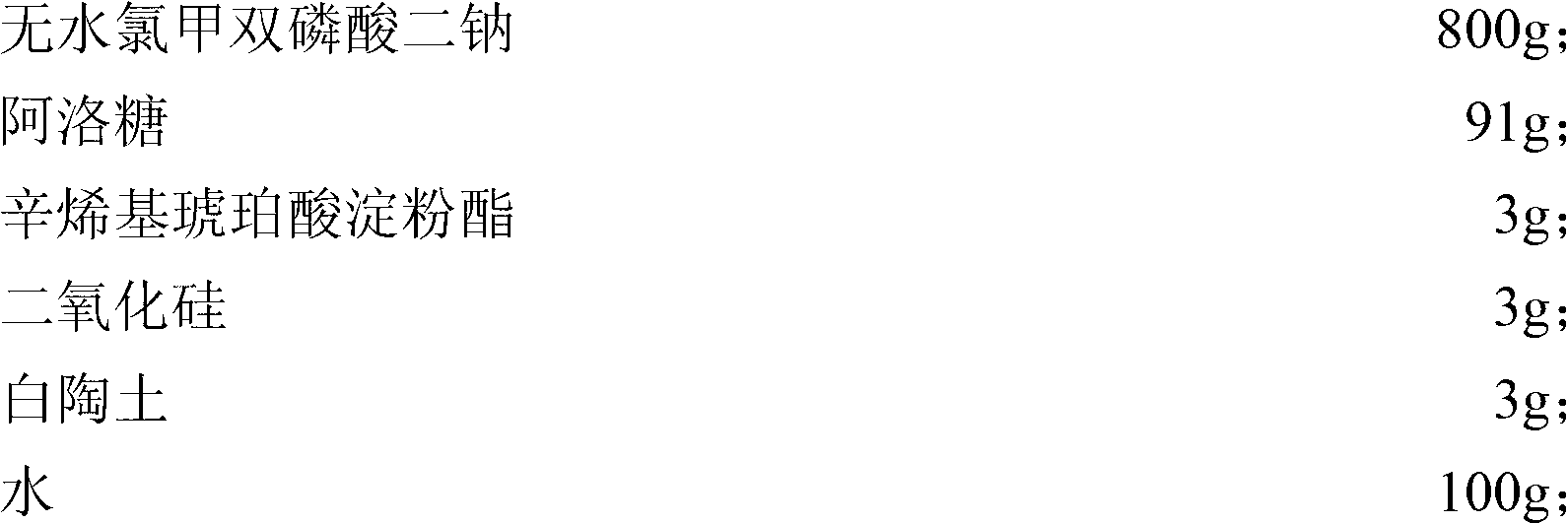

[0041] A kind of anhydrous disodium clometris phosphate medicine tablet, adopts the raw material of following percentage by weight:

[0042]

[0043] Dry allose, starch octenyl succinate, silicon dioxide and kaolin together and pass through a 1mm sieve, then add anhydrous disodium chloroformate and water and mix well, use 9× 20mm punching machine, made into anhydrous chlormedate disodium pharmaceutical tablets with an average weight of 1190mg (±2%).

Embodiment 2

[0045] A kind of anhydrous disodium clometris phosphate medicine tablet, adopts the raw material of following percentage by weight:

[0046]

[0047] Dry allose, starch octenyl succinate, silicon dioxide and kaolin together and pass through a 1mm sieve, then add anhydrous disodium chloroformate and water and mix well, use 9× 20mm punching machine, made into anhydrous chlormedate disodium pharmaceutical tablets with an average weight of 1190mg (±2%).

[0048] Prepare the anhydrous chlormedipate disodium pharmaceutical tablet (tablet A) of embodiment 1 and the anhydrous chlormedipate disodium pharmaceutical tablet (tablet B) of embodiment 2 under different tabletting speeds, and investigate Its crushing strength and fragility, the specific test results are shown in Table 1. The test of tablet crushing strength and friability refers to the method specified in the French Pharmacopoeia (10th edition in 1993, V.5.1) "Friability of Tablets".

[0049] Table 1

[0050] T...

Embodiment 3

[0053] A kind of anhydrous disodium clometris phosphate medicine tablet, adopts the raw material of following percentage by weight:

[0054]

[0055] Dry allose, starch octenyl succinate, silicon dioxide and kaolin together and pass through a 1mm sieve, then add anhydrous disodium chloroformate and water and mix well, use 9× 20mm punching machine, made into anhydrous chlormedate disodium pharmaceutical tablets with an average weight of 1190mg (±2%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com