Glass fiber reinforced plastic pultrusion and grading heating pre-forming device and method

A graded heating and preforming technology, which is applied in the field of FRP pultrusion graded heating preforming device, can solve the problems that the product cannot be finally formed, the resin pot life is shortened, and the pultrusion production speed is reduced, so as to improve the product forming degree and pultrusion Speed, ensure internal and external curing, improve the effect of resin fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

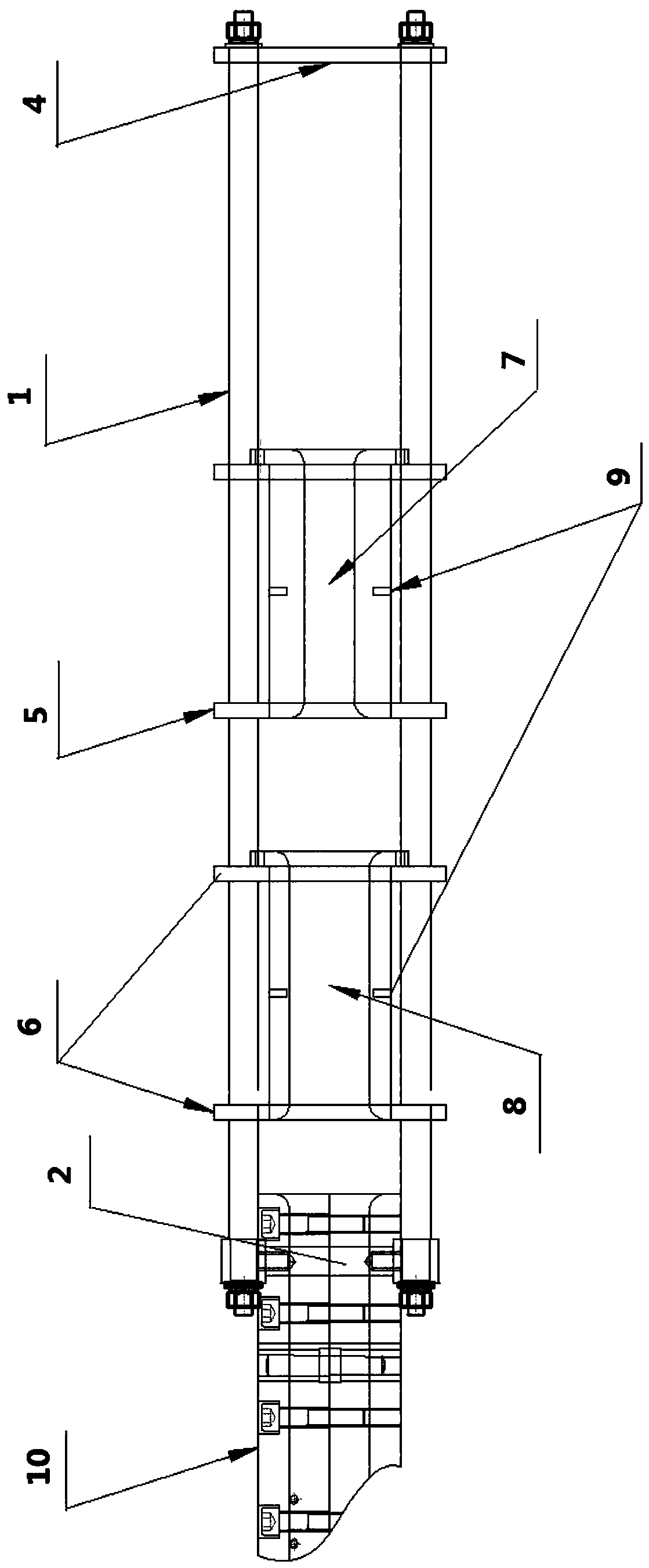

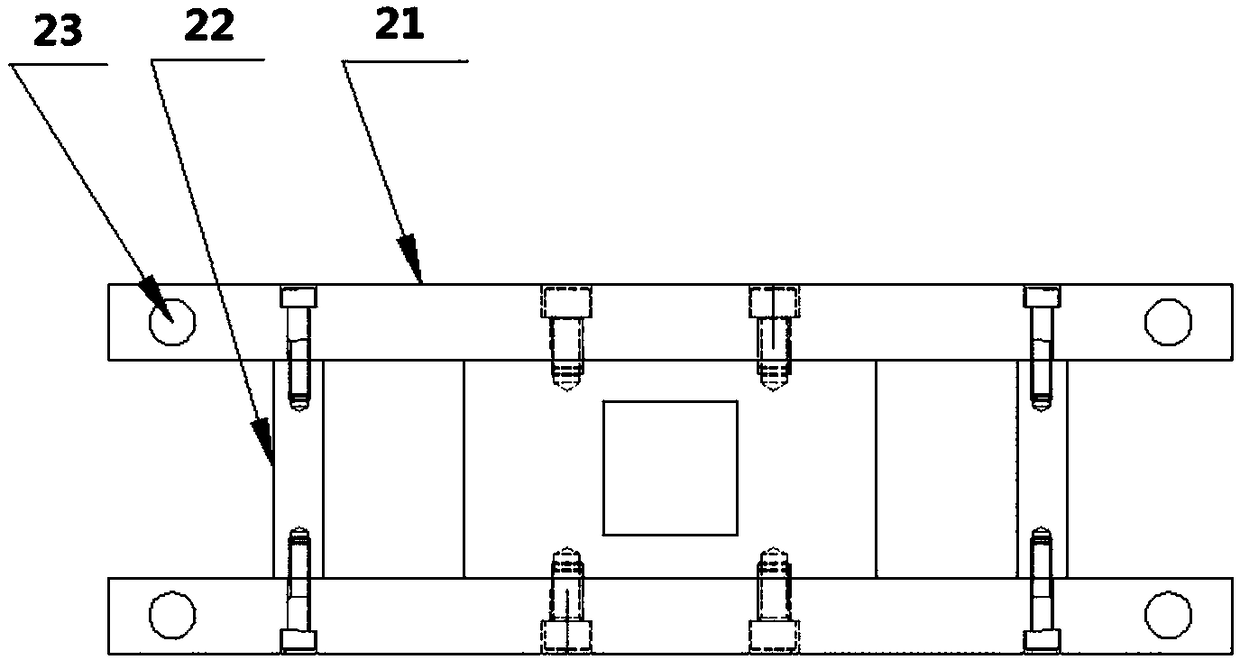

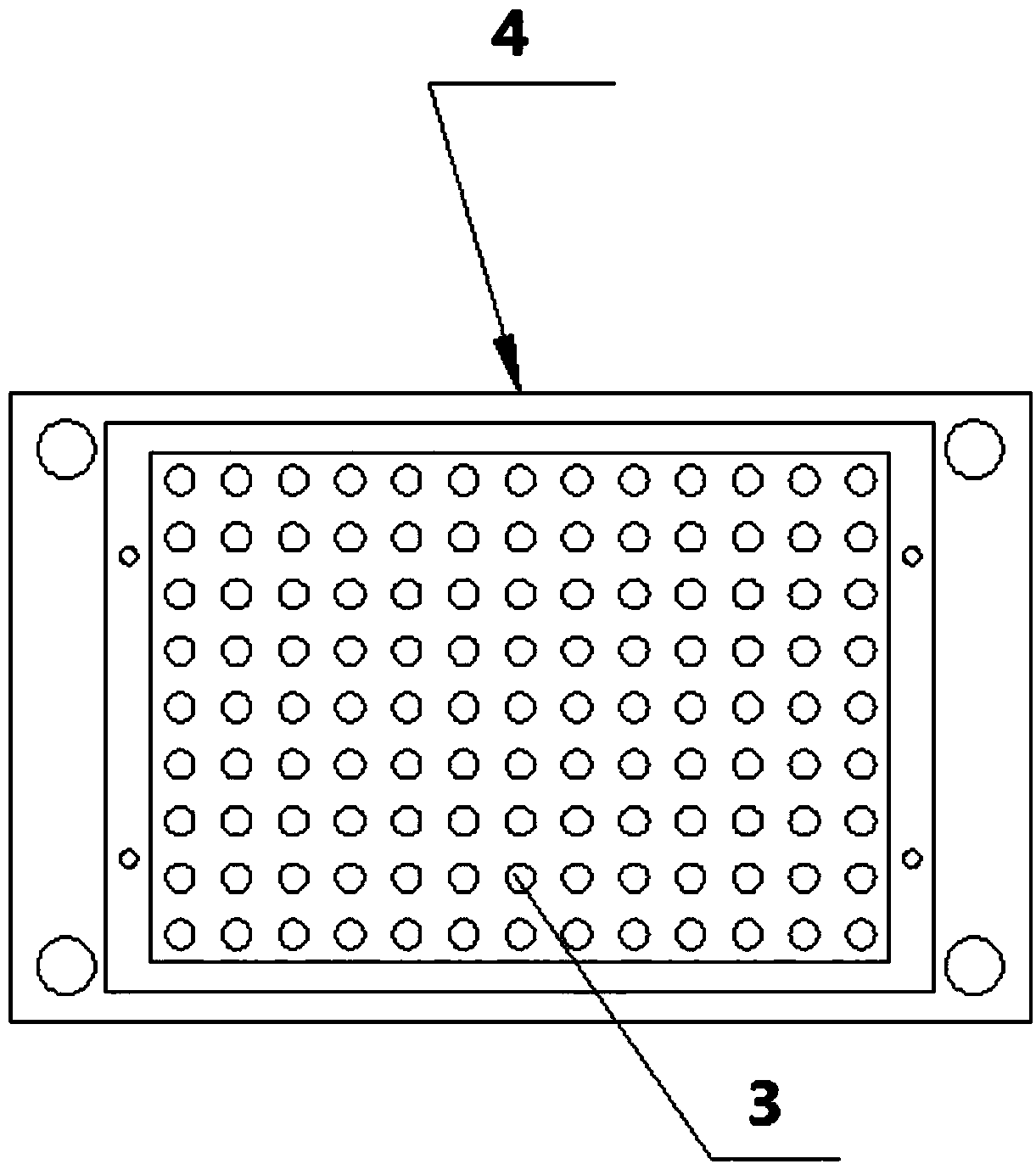

[0025] Embodiment 1, with reference to figure 1 , figure 2 , a FRP pultrusion graded heating preforming device, the device includes a support frame composed of a number of support rods 1, on which a yarn threading plate 4, a yarn positioning plate 5 and a preforming Heating mold support plate 6, several yarn penetration holes 3 are distributed on the described yarn penetration plate 4 and yarn positioning plate 5; secondary preheating mold 8 is fixed on the preheating mold support plate 6, and the yarn positioning A first-level preheating mold 7 is fixedly installed on the plate 5; the device is also provided with a fixed connector 2, and the fixed connector 2 includes a fixed plate 21 and a support column 22 connected to support the fixed plate 21. The support frame is fixedly connected to the molding die 10 .

[0026] refer to figure 2 , the support column 22 is a cylindrical pin with internal thread. A connecting through hole 23 is provided on the fixing plate 21 , th...

Embodiment 2

[0032] Example 2, the cavity size of the primary preheating mold 7 is smaller than the cavity size of the secondary preheating mold 8, and the volume content of fibers in both mold cavities is 65%. The mold entrance and exit fillets of the primary preheating mold 7 and the secondary preheating mold 8 are larger than R20mm.

[0033] The length of the heating section of the first-stage preheating mold 7 and the second-stage preheating mold 8 is 20 cm. The first-level preheating mold 7 and the second-level preheating mold 8 are equipped with several temperature measuring holes 9, at least one of which is used to control heating, and at least one is used to calibrate the temperature.

[0034] The distance between the first-level preheating mold 7 and the second-level preheating mold 8 is 20cm; the second-level preheating mold 8 is 10cm from the entrance length of the forming mold 10; the first-level preheating mold 7 The length apart from threading plate 8 is 80cm.

[0035] All ...

Embodiment 3

[0036] Embodiment 3, a FRP pultrusion graded heating preforming method, the method uses the FRP pultrusion graded heating preforming device described in Embodiment 1 or 2, and the steps are as follows: the yarn soaked in the resin glue solution passes through the yarn passing plate 4. The middle part of the yarn enters the first-level preheating mold 7 from the yarn passing plate 4 and performs a first-level preheating at 100°C. Together enter the secondary preheating mold 8 and perform secondary preheating at 90°C to complete the graded heating preforming; then all the yarns enter the forming mold 10, and finally solidify and form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com