Meat pickling powder and preparation method and use method thereof

A technology of meat powder and meat products, applied in the field of food seasoning, which can solve the problems of harm to the human body, not achieving the best effect, and the rehydration property needs to be improved, so as to achieve good taste, improve the curing effect, and overcome the effect of single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A cured meat powder, comprising 50 parts of cornstarch, 20 parts of baking soda, 0.2 parts of papain, 2 parts of glucose, 10 parts of table salt, 5.5 parts of monosodium glutamate, and 11 parts of sodium tripolyphosphate.

[0051] Concrete preparation method comprises the following steps:

[0052] (1) Raw material acceptance: sampling the raw materials, and inspecting the various quality indicators of the sampled samples according to the "National Standards" and "Enterprise Standards", combined with the actual situation of the enterprise;

[0053] (2) weighing each raw material according to parts by weight;

[0054] (3) Mixing and stirring: evenly mix one or its compound of cornstarch, baking soda, papain, glucose, salt, etc., which is cured meat powder;

[0055] (4) The bacon powder is weighed, packaged and preserved.

[0056] The specific process of weighing, packaging and preserving cured meat powder includes the following steps:

[0057] (4.1) Weighing: quantitat...

Embodiment 2

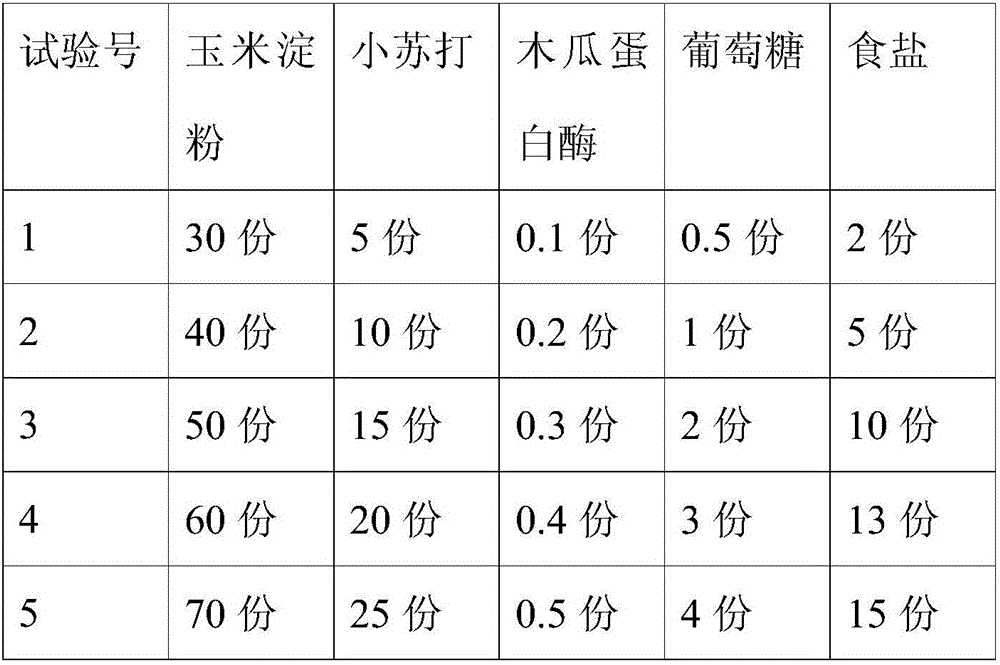

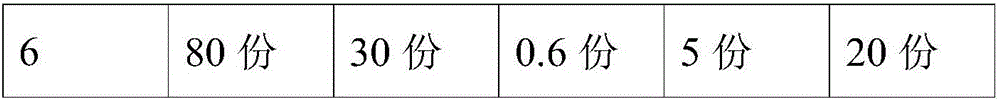

[0063] In order to determine the weight ratio of each raw material, 6 groups of raw material ratios selected based on a large amount of practical experience in the past were used as comparative tests, and the optimal raw material ratio range was selected through the customer's evaluation. The specific steps are:

[0064] Prepare 6 groups of cured meat powder, number each group of cured meat powder from 1 to 6, and marinate beef separately. Each group is measured by a catty of beef for a comparative test of marinating. The specific marinating process is: add 10g of salt, 8g of chicken essence, marinate Make the beef sticky to the touch; then dissolve 15g of bacon powder in 100g of water according to the number to make 6 groups of marinade; add the 6 groups of marinade to the beef and stir evenly, and add the marinade to the beef in 3 times. Stir and marinate for 30 minutes; put the marinated beef into the refrigerator for 3 hours, and the parts by weight of each group of raw mat...

Embodiment 3

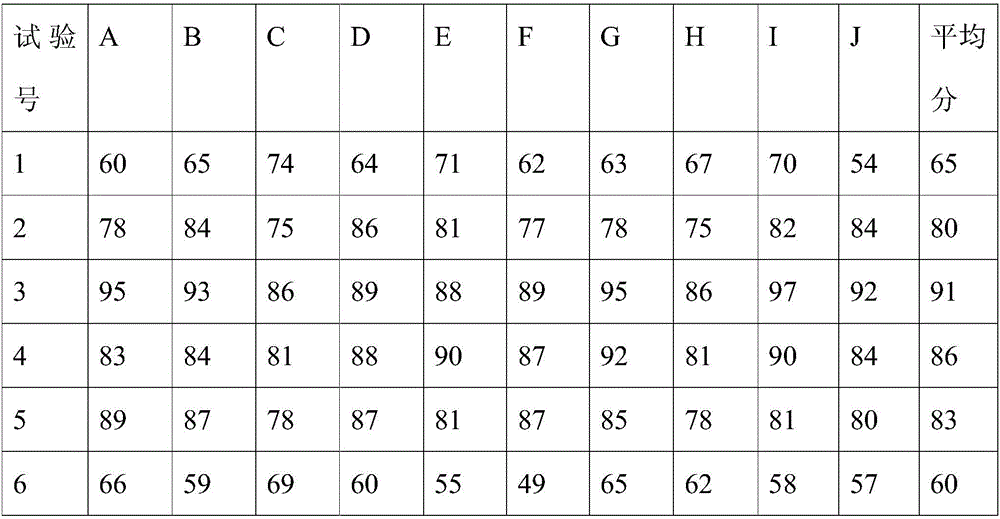

[0073] According to above-mentioned embodiment, can draw the range value of each raw material weight ratio of bacon powder, but the optimal proportioning scheme of bacon powder needs to carry out further test and analysis, present embodiment adopts orthogonal test method to obtain the optimal ratio of raw material The best ratio plan, the specific steps are:

[0074] Take the 2, 3, 4, and 5 groups with the highest scores, among which there are 5 influencing factors, and each factor has 4 levels. If the test is carried out according to the comprehensive test method, 4 tests are required. 5 (1024) tests, the steps are very cumbersome, the orthogonal test method is a design method of multi-factor and multi-level research, it selects some representative points from the comprehensive test according to the orthogonality, and these are useful The representative points have the characteristics of "evenly dispersed, neat and comparable". Orthogonal experiment is the main method of anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com