Nitrogen and phosphorus removal ecological permeable material and preparation method thereof

A technology for permeable material, denitrification and phosphorus removal, applied in chemical instruments and methods, biological water/sewage treatment, ceramic products, etc., can solve problems such as hardening and blocking, and achieve the effect of avoiding hardening and blocking, not easy to block, and avoiding hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

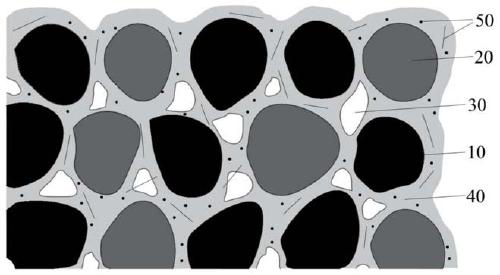

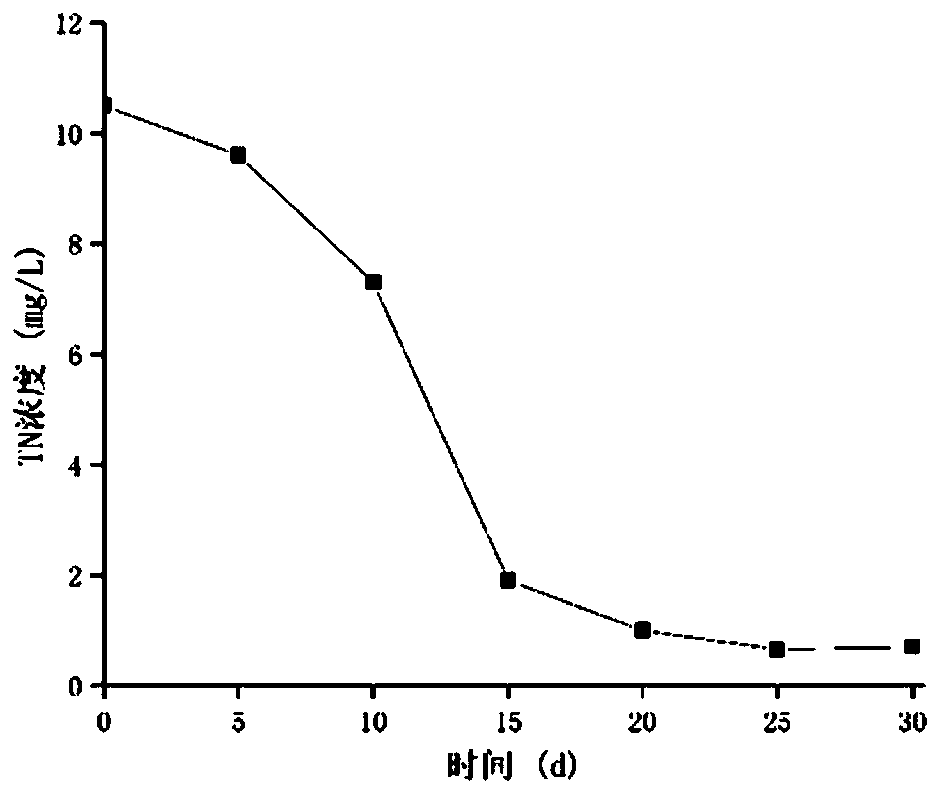

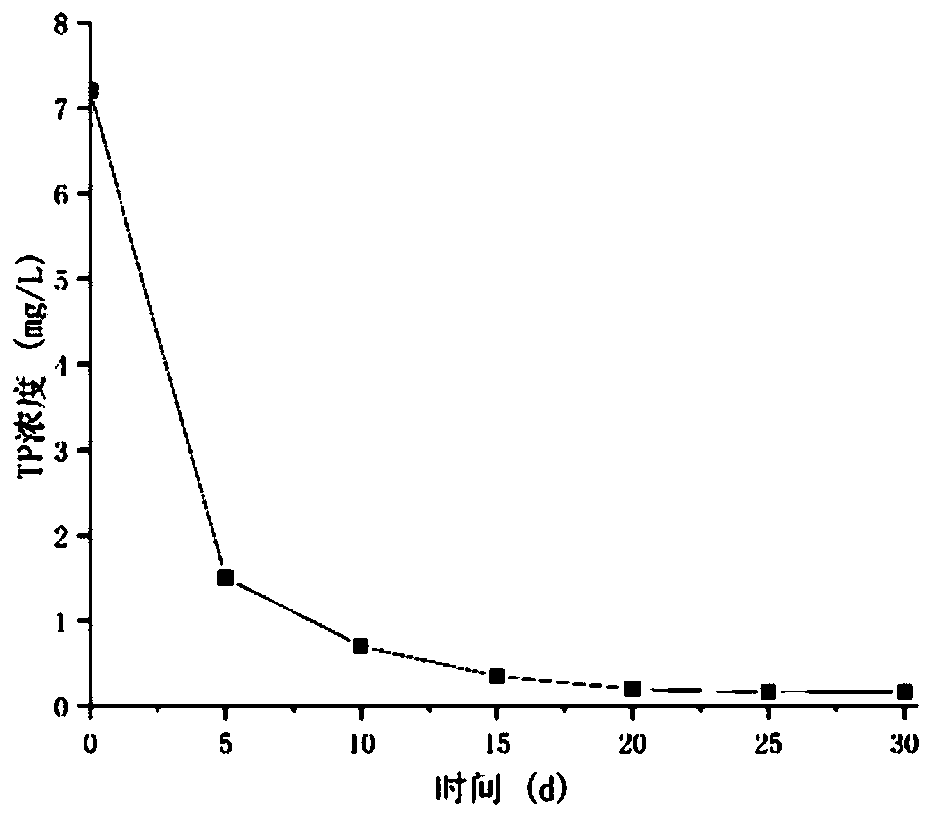

[0042] The preparation method of a kind of denitrification and dephosphorization ecological permeable material of the present invention comprises the aggregate of 0-50 parts by weight, the pyrite of 30-80 parts, the cohesive material of 10-25 parts, 0.15 - 0.5 parts of fiber reinforcement and 4-10 parts of water are raw materials, among which the particle size range of pyrite and aggregate particles is 5-30mm, both of which are coarse particles, between the coated particles It can not only adhere to each other to form a stable skeleton structure, but also form gaps between particles as water-permeable pores; the cohesive material includes the following mass fractions: silicate cohesive material 60-90%, silica fume 5-20% , diatomite 5-20% (based on the total mass of the coagulated material as 100%); through the sequential batch method of adding raw materials, the coagulated material and fiber reinforcement can more fully and evenly wrap the aggregate and sulfur iron ore, the sp...

Embodiment 1

[0045] The mass fraction ratio of raw materials is: 40% sandstone with a particle size of 10mm-20mm, 40% pyrite with a particle size of 10mm-20mm, 10.75% cement, 2.5% silica fume, 2.5% diatomaceous earth, 4% water and 0.25% glass fiber length 3mm-10mm. Mix and stir sand, pyrite, and 1 / 2 of the total mass of the above water at a stirring speed of 60r / min and a stirring time of 60s to obtain a wet mixture; mix cement, silica fume, diatomaceous earth, and glass fiber To obtain dry powder mortar evenly, add 1 / 2 of the total amount of the above dry powder mortar into the wet mixture and stir at a stirring speed of 100r / min for 120s; mix 1 / 2 of the remaining total amount of water with the remaining 1 / 2 2 dry powder mortar is alternately added to the above mixture and stirred evenly to obtain a slow-release slurry, the stirring speed is 100r / min, and the stirring time is 200s; after the stirred slow-release slurry is poured into a module of the required size and shape, remove Mold m...

Embodiment 2

[0047] The mass fraction ratio of raw materials is: 38% sandstone with a particle size of 10mm-20mm, 38% pyrite with a particle size of 10mm-20mm, 13.75% cement, 3% silica fume, 3% diatomaceous earth, 4% water and 0.25% glass fiber length 3mm-10mm. Mix and stir sand, pyrite, and 1 / 2 of the total mass of the above water at a stirring speed of 60r / min and a stirring time of 60s to obtain a wet mixture; mix cement, silica fume, diatomaceous earth, and glass fiber To obtain dry powder mortar evenly, add 1 / 2 of the total amount of the above dry powder mortar into the wet mixture and stir at a stirring speed of 100r / min for 120s; mix 1 / 2 of the remaining total amount of water with the remaining 1 / 2 Add the dry powder mortar of 2 alternately to the above mixture and stir evenly to obtain a slow-release slurry, the stirring speed is 60r / min, and the stirring time is 200s; after the stirred slurry is poured into the module of the required size and shape, demoulding and curing Forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com