A kind of iron base-bentonite/carbon composite porous material, its preparation method and application

A technology of porous materials and bentonite, which is applied in the field of environmental restoration, can solve the problems of large powder density differences, uneven dispersion, and coating in the skeleton, and achieve the effects of low production cost, uniform contact dispersion, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

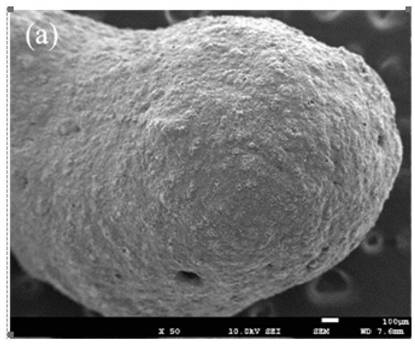

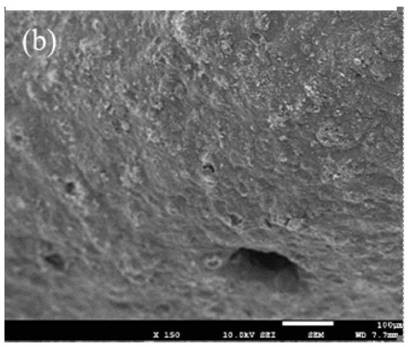

[0073] This example provides a method for preparing an iron-based-bentonite / carbon composite porous material, the specific preparation method of which is:

[0074] (1) prepare 2wt% sodium alginate solution as the dispersant of iron powder, the forming agent of pyrolysis precursor;

[0075] (2) 1 g of reduced iron powder with a size of 400 mesh, 3 g of bentonite and 20 mL of the solution described in step (1) were mechanically mixed for 35 min to obtain a pasty mixture;

[0076] (3) adding the pasty mixture described in step (2) into a 0.5 mol / L calcium ion solution by dripping it into a pyrolysis precursor solidified for 4 hours into a spherical shape;

[0077] (4) Place the pyrolytic precursor obtained in step (3) in an atmosphere furnace and roast in a nitrogen atmosphere. The calcination temperature was 600° C., the heating rate was 5° C. / min, and the calcination time was 2 hours to obtain an iron-based-bentonite / carbon composite porous material.

[0078] The iron-based-b...

Embodiment 2

[0081] This example provides the preparation method of iron-based-bentonite / carbon composite porous material, and its specific preparation method is:

[0082] (1) prepare 2wt% sodium alginate solution as the dispersant of iron powder, the forming agent of pyrolysis precursor;

[0083] (2) 1 g of reduced iron powder with a size of 400 mesh, 0.1 g of starch, 3 g of bentonite and 20 mL of the solution described in step (1) were mechanically mixed for 35 minutes to obtain a pasty mixture;

[0084] (3) adding the pasty mixture described in step (2) into a 0.5 mol / L calcium ion solution by dripping it into a pyrolysis precursor solidified for 4 hours into a spherical shape;

[0085] (4) Place the pyrolytic precursor obtained in step (3) in an atmosphere furnace and roast in a nitrogen atmosphere. The calcination temperature was 600° C., the heating rate was 5° C. / min, and the calcination time was 2 hours to obtain an iron-based-bentonite / carbon composite porous material.

[0086] ...

Embodiment 3

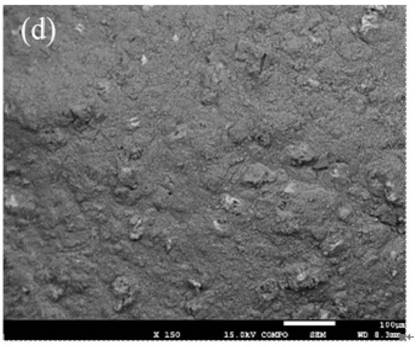

[0089] This example provides the preparation method of iron-based-bentonite / carbon composite porous material, and its specific preparation method is:

[0090] (1) prepare 2wt% sodium alginate solution as the dispersant of iron powder, the forming agent of pyrolysis precursor;

[0091] (2) 1g of reduced iron powder with a size of 400 mesh, 0.3g of starch, 3g of bentonite and 20mL of the solution described in step (1) were mechanically mixed for 35min to obtain a pasty mixture;

[0092] (3) adding the pasty mixture described in step (2) into a 0.5 mol / L calcium ion solution by dripping it into a pyrolytic precursor solidified for 4 hours into a spherical shape;

[0093] (4) Place the pyrolytic precursor obtained in step (3) in an atmosphere furnace and roast in a nitrogen atmosphere. The calcination temperature was 600° C., the heating rate was 5° C. / min, and the calcination time was 2 hours to obtain an iron-based-bentonite / carbon composite porous material.

[0094] The iron-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com