Boiler desulfurization slaked lime bin discharge system

A technology of slaked lime silo and lime silo, which is applied in the field of boiler desulfurization, can solve the problems of slaked lime silo without external discharge system, frequent start and stop of desulfurization equipment, and inability to discharge, so as to reduce operational risks, avoid hardening and blockage, and save plant use. the effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

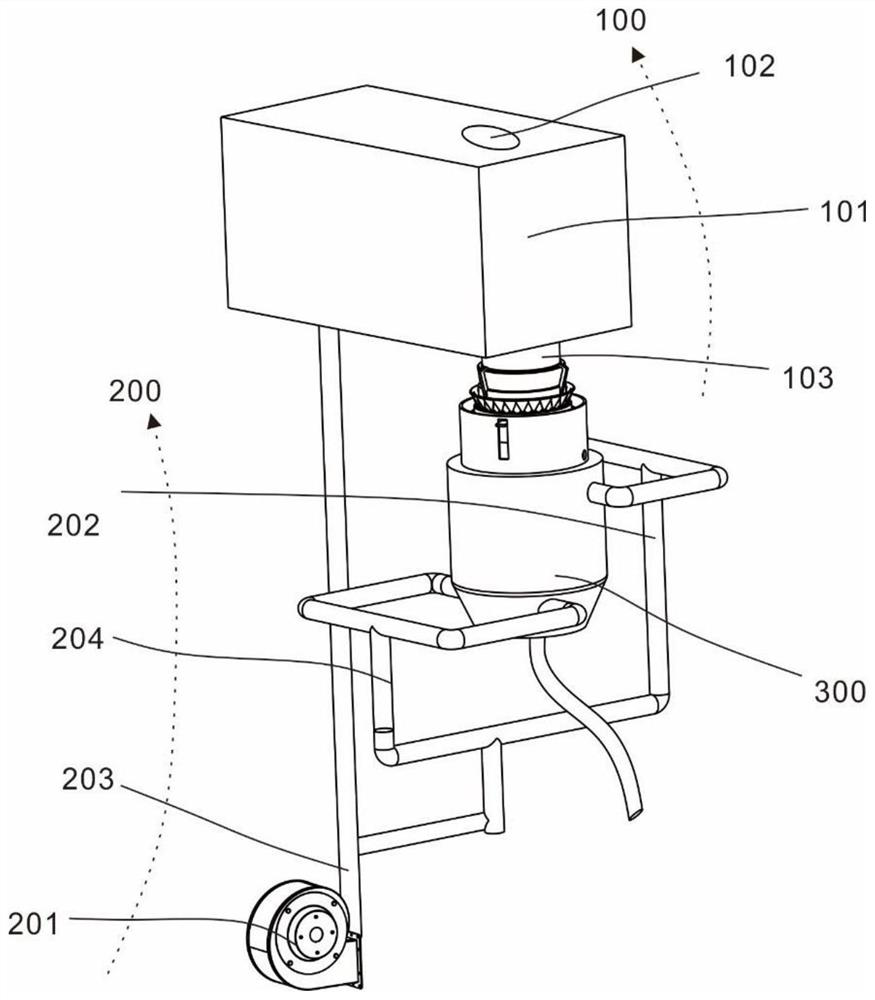

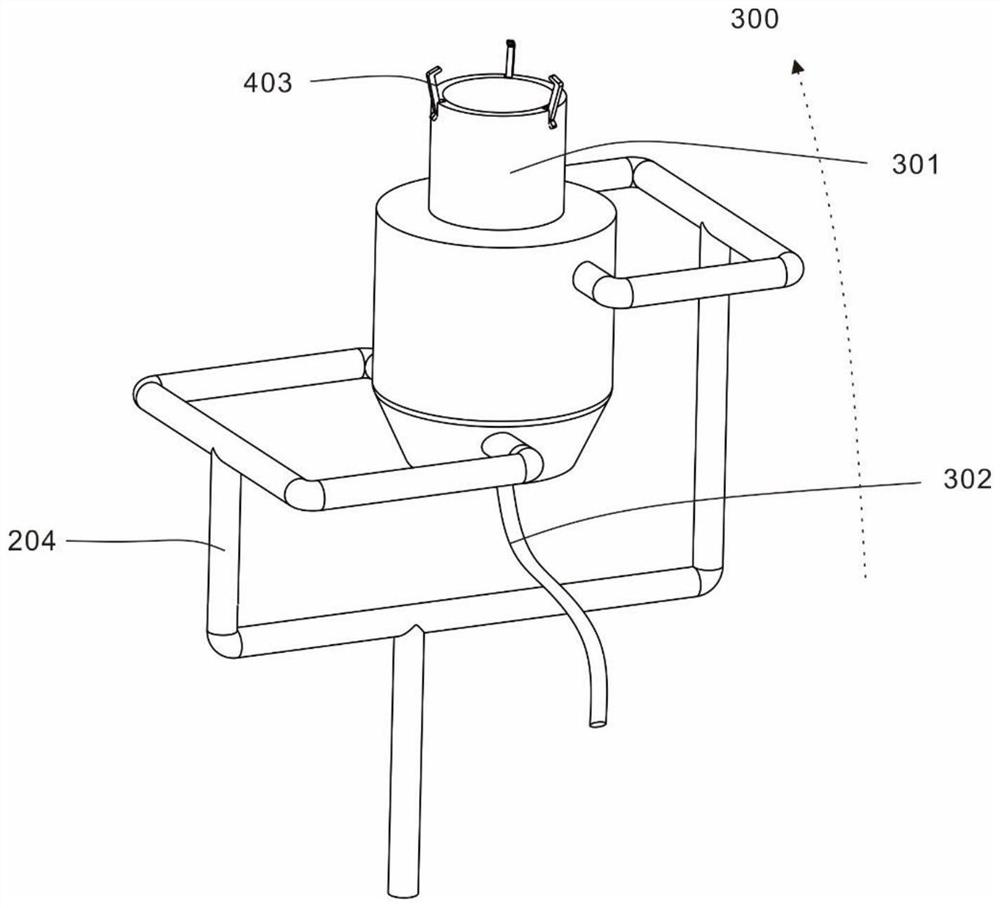

[0023] This embodiment provides a boiler desulfurization slaked lime silo discharge system, such as Figure 1 ~ Figure 2

[0024] A boiler desulfurization slaked lime bin discharge system, which includes a lime bin 100, the lime bin 100 includes a casing 101, an ash inlet 102, and ash discharge port 103, the casing 101 forms the overall shape of the lime bin 100, and the ash inlet 102 is located in the lime bin 100, the ash outlet 103 is located at the lower end of the lime bin 100, and the ash outlet 103 is connected to the one-way valve 300; the anti-clogging mechanism 200, the anti-clogging mechanism 200 includes a fan 201 and a first pipeline 202, and one end of the first pipeline 202 is fixedly connected The exhaust port of the fan 201 and the other end of the first pipe 202 are connected to the one-way valve 300;

[0025] Quicklime enters the lime bin 100 from the ash inlet 102, and the lime bin 100 is used to store quick lime, and the lime bin 103 can discharge the qui...

Embodiment 2

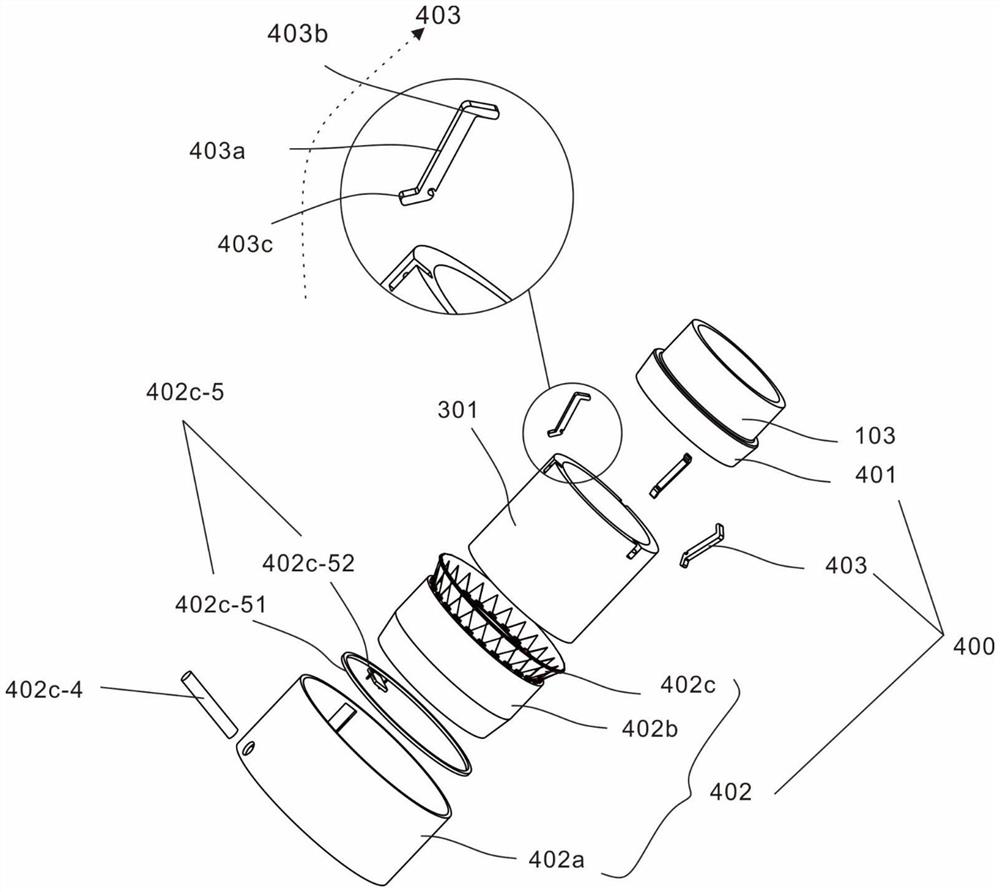

[0032] This embodiment provides a boiler desulfurization slaked lime silo discharge system, such as Figure 1 ~ Figure 4 , this embodiment is based on embodiment 1 but differs from embodiment 1 in that:

[0033] A connection assembly 400 is provided at the connection between the one-way valve 300 and the lime bin 100. The connection assembly 400 includes a first connection piece 401, a switching mechanism 402 and a second connection piece 403. The first connection piece 401 is arranged at the lower end of the ash discharge port 103, and The second connecting piece 403 is located at the upper end of the one-way valve 300 , and the switching mechanism 402 is located above the second connecting piece 403 .

[0034] The switching mechanism 402 includes a fixed ring 402a, a lifting ring 402b and a locking member 402c. One end of the fixing ring 402a is fixed on the one-way valve 300, and a ring groove is formed between the fixing ring 402a and the one-way valve 300, and the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com