Preparation method of aluminum-free transparent laser environmental-protection inner liner for cigarette

A cigarette lining paper, transparent technology, applied in the field of lining paper, can solve the problems of unclear and accurate printed fonts, poor flexibility and formability of paper, easy to rebound and not resistant to folding, etc., and achieve clear and accurate printed fonts. Good flexibility and formability, solving the effect of unclear embossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments.

[0026] In the present invention, the lining paper is made according to the following steps:

[0027] The PET film is molded into laser patterns of various patterns by a molding machine, and then compounded with paper with water-based transfer glue; after peeling off the PET film, the laser pattern is transferred to the paper;

[0028] Use a vacuum aluminum coating machine to coat a layer of transparent medium on the stripped paper with laser patterns;

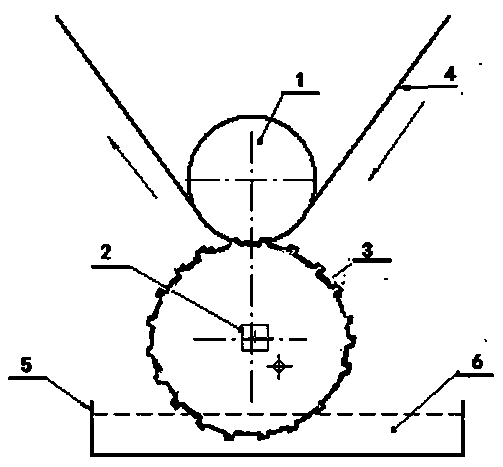

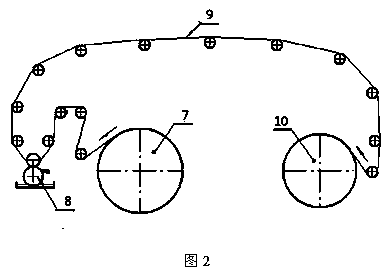

[0029] The paper with laser laser patterns coated with transparent medium is subjected to water replenishment process; the water replenishment process includes the following steps: prepare replenishment solution 6 according to the ratio of 70 kg of pure water, 10 kg of acrylic resin, and 20 kg of alcohol, and prepare the prepared The rehydration solution 6 is poured into the water tank 5, the rolled paper is put into the roll coating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com