Lost foam casting method

A technology of lost foam casting and castings, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex casting process, low molding efficiency, low sand casting production efficiency, etc., and achieve low raw material and equipment costs. , The effect of solving difficult molding and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core idea of the present invention is to select the foam mold made of foam as the casting material for casting, lay high-temperature-resistant raw sand around the foam mold, and then pour into the foam mold until the foam mold gradually disappears. , you can get the scheduled casting.

[0029] EPS is polystyrene foam (Expanded Polystyrene) is a light polymer.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

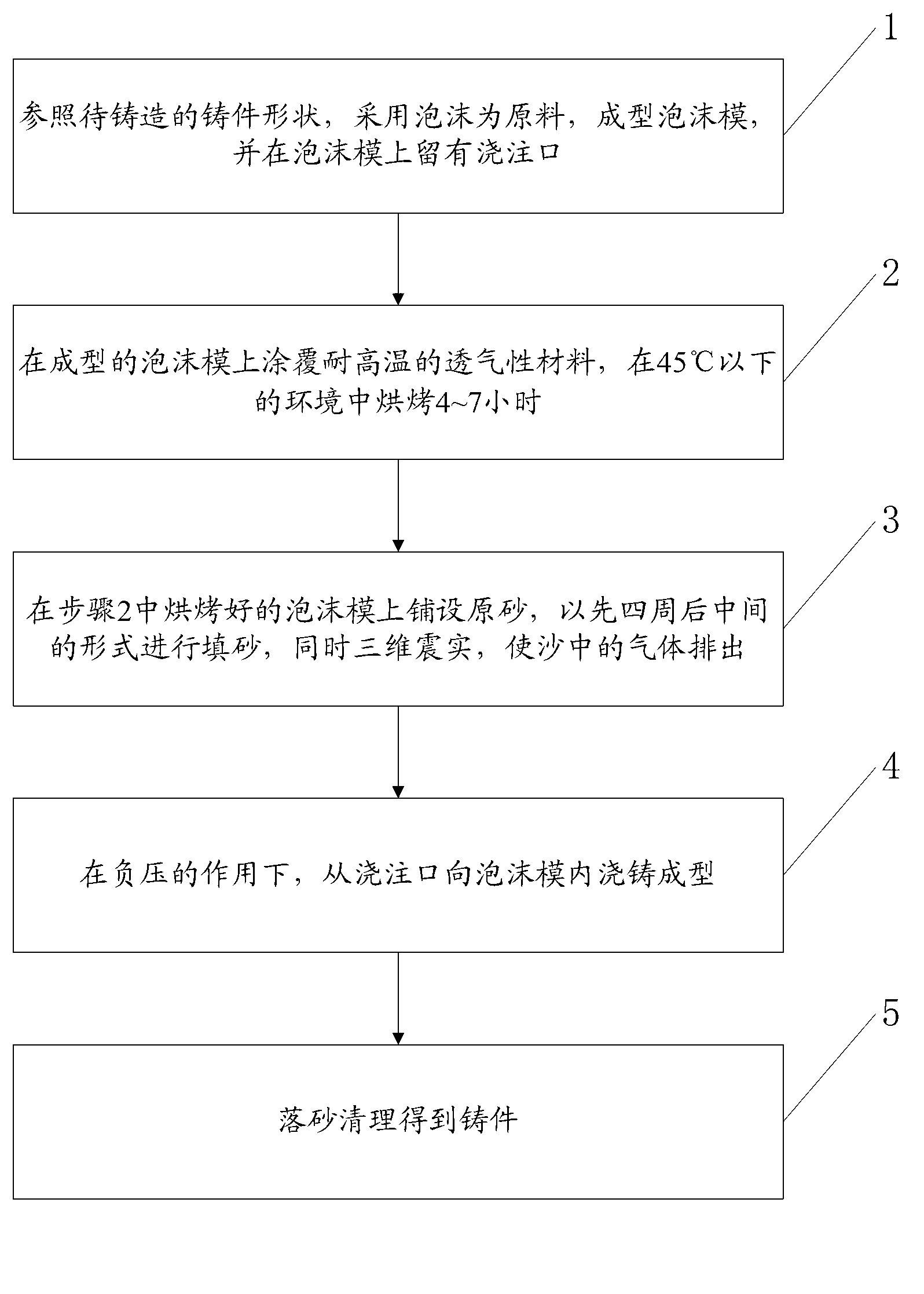

[0031] see figure 1 , a lost foam casting method, the specific steps comprising:

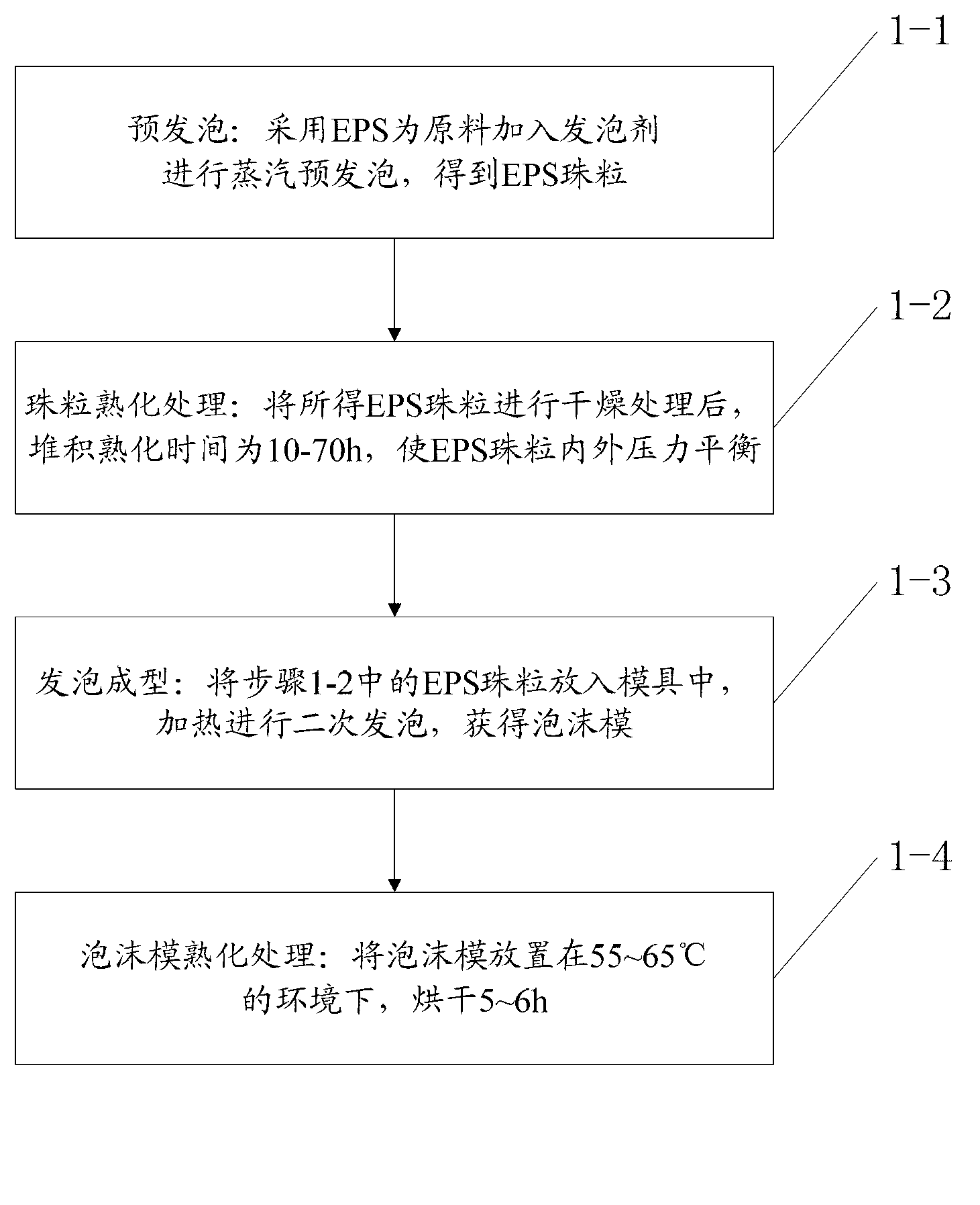

[0032] Step 1. Refer to the shape of the casting to be cast, use foam as raw material, form a foam mold, and leave a sprue on the foam mold;

[0033] Step 2. Coat the formed foam mold with a high-temperature-resistant air-permeable material, and bake in an environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com