Method for preparing egg substitute based on soy isolate protein and product

A soybean protein isolate and substitute technology, applied in the field of food processing, can solve the problems of expensive equipment, not much attention to the comparison of nutritional characteristics, complex processing procedures, etc., to achieve improved gel quality, low fat, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

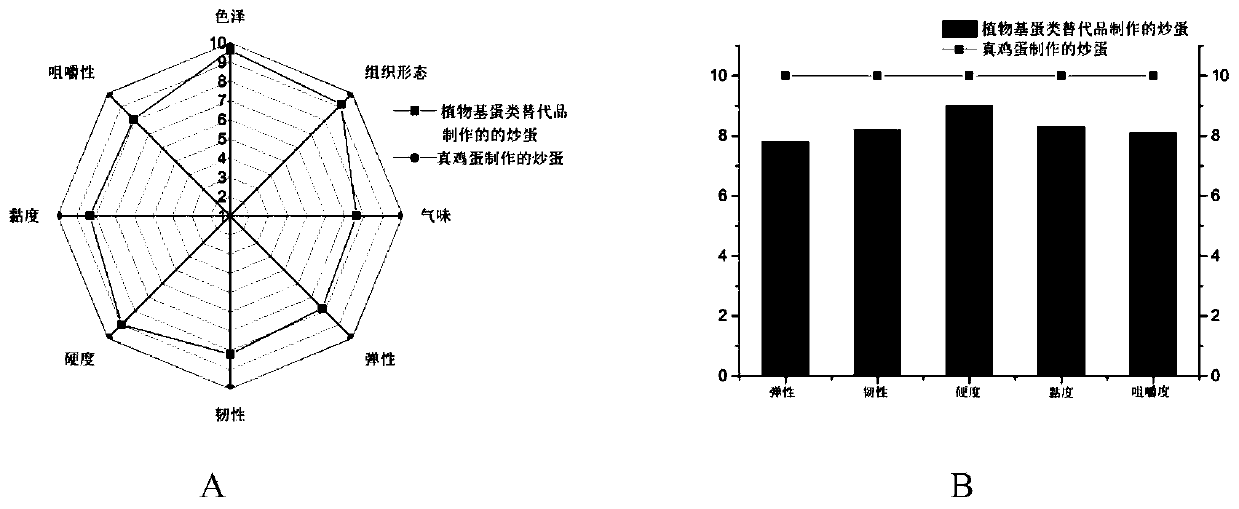

Image

Examples

Embodiment 1

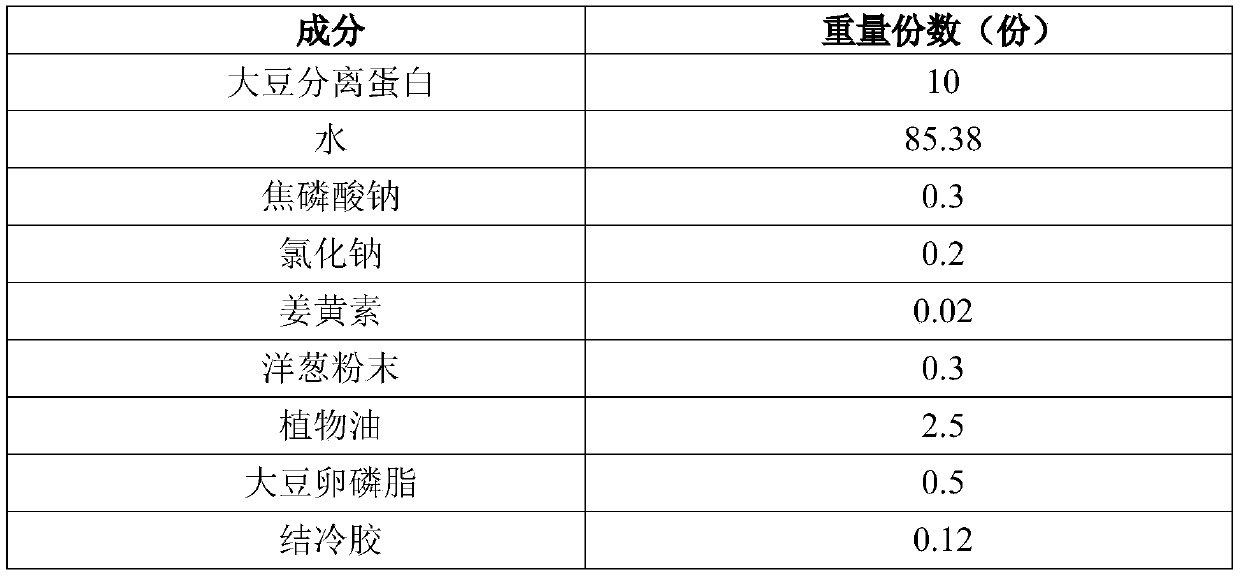

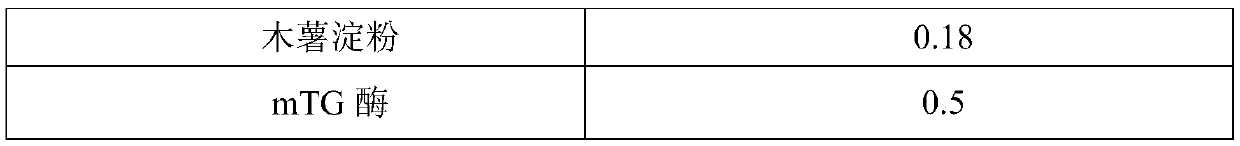

[0031] A method for preparing an egg substitute based on soybean protein isolate, the proportioning of each raw material component is as follows:

[0032]

[0033]

[0034] Specific steps are as follows:

[0035] (1) After mixing soybean protein isolate and water evenly in proportion, sodium pyrophosphate, sodium chloride, curcumin and onion powder were added in sequence to carry out shearing and mixing respectively to obtain mixture I; when each component was added, shearing Stir for 3 minutes and fully mix with soybean protein isolate, and the shear rate of shear stirring is 25000r / min.

[0036] (2) Add vegetable oil and soybean lecithin to mixture I, carry out emulsification reaction by shearing and stirring, and obtain emulsified mixture;

[0037] (3) Take the emulsified mixture, add the mixture of gellan gum and tapioca starch therein, and stir and mix to obtain the mixture II; when each component is added, stir for 3 minutes and fully mix with soybean protein isol...

Embodiment 2

[0075] A method for preparing an egg substitute based on soybean protein isolate, the proportioning of each raw material component is as follows:

[0076]

[0077]

[0078] Specific steps are as follows:

[0079] (1) After mixing soybean protein isolate and water evenly in proportion, sodium pyrophosphate, sodium chloride, curcumin and onion powder were added in sequence to carry out shearing and mixing respectively to obtain mixture I; when each component was added, shearing Stir for 3 minutes and fully mix with soybean protein isolate, and the shear rate of shear stirring is 30000r / min.

[0080] (2) Add vegetable oil and soybean lecithin to mixture I, carry out emulsification reaction by shearing and stirring, and obtain emulsified mixture;

[0081] (3) Take the emulsified mixture, add the mixture of gellan gum and tapioca starch therein, and stir and mix to obtain the mixture II; when each component is added, stir for 3 minutes and fully mix with soybean protein isol...

Embodiment 3

[0086] A method for preparing an egg substitute based on soybean protein isolate, the proportioning of each raw material component is as follows:

[0087]

[0088]

[0089] Specific steps are as follows:

[0090](1) After mixing soybean protein isolate and water evenly in proportion, sodium pyrophosphate, sodium chloride, curcumin and onion powder were added in sequence to carry out shearing and mixing respectively to obtain mixture I; when each component was added, shearing Stir for 3 minutes and fully mix with soybean protein isolate, and the shear rate of shear stirring is 20000r / min.

[0091] (2) Add vegetable oil and soybean lecithin to the mixture I, carry out the emulsification reaction by shearing and stirring, and obtain the emulsified mixture;

[0092] (3) Take the emulsified mixture, add a mixture of gellan gum and tapioca starch therein, and stir to obtain the mixture II; when each component is added, stir for 3 minutes and fully mix with soybean protein iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com