Biological self-repair depth profile control slug combination and its application method

A self-healing, biopolymer technology, applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc., can solve problems such as poor formation shear resistance, adverse impact on the environment, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

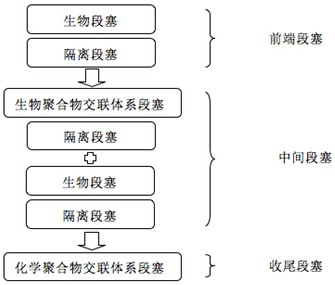

Method used

Image

Examples

Embodiment 1

[0024] The bio-slug consists of living microorganisms that produce biopolymers and their fermentation products, biopolymers, and fermented nutrients. The living microorganism is Sphingomonas sphingomonas, which can reproduce and reproduce polymers at a reservoir temperature of 40°C. The fermentation nutrient is 38g / L sucrose, 1.6g / L peptone, and 0.6g beef extract / L,K 2 HPO 4 0.4g / L, fermented in the environment of NaCl0.1g / L, the biopolymer content produced is 3% (w / v), the viscosity is at 4000mPa·s; the bacterial cell content in the fermented liquid is 0.1% (w / v).

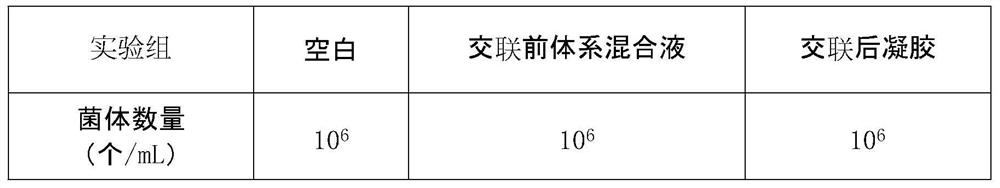

[0025]The mass percentage of scleroglucan in the biopolymer crosslinking system slug is 0.08% and the composition of crosslinking agent, the mass percentage of sodium dichromate in the crosslinking agent is 0.3%, the mass percent of sodium dithionite The percentage content is 0.15%. The gelling time is 264 hours, and the gelling strength is D (gel code). This biopolymer has strong shear resistance. The impac...

Embodiment 2

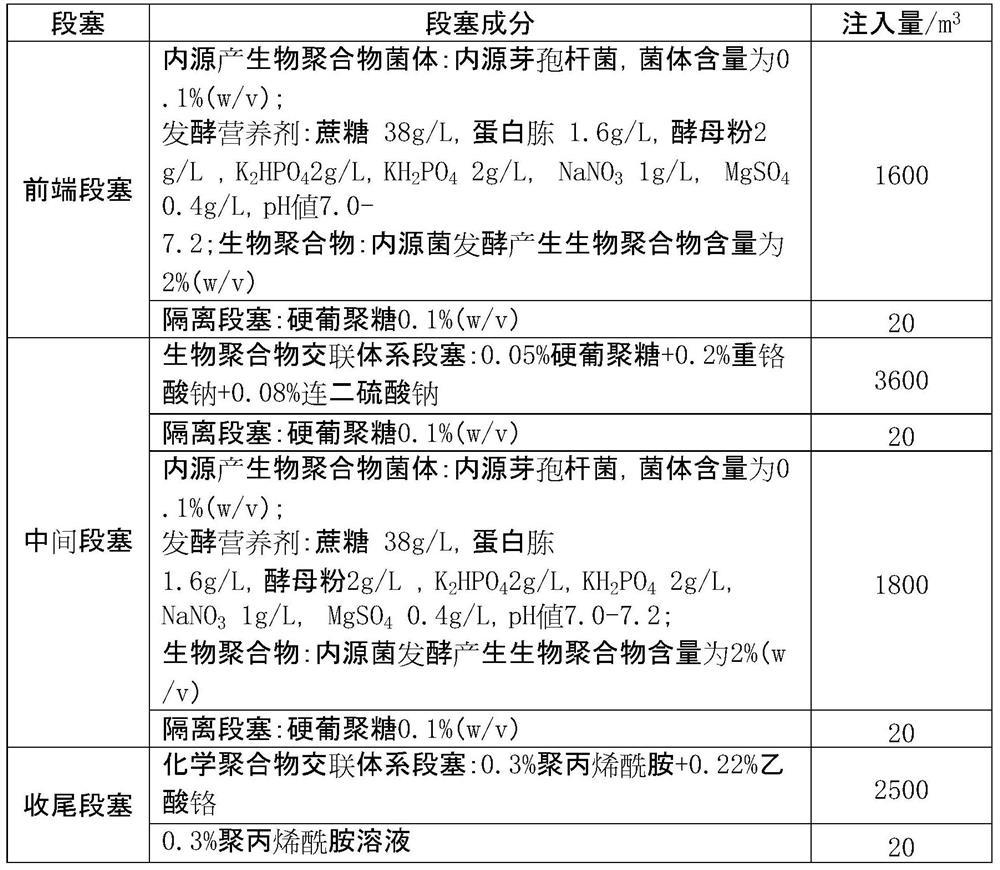

[0029] The bio-slug consists of living microorganisms that produce biopolymers and their fermentation products, biopolymers, and fermented nutrients. The living microorganisms are Bacillus bacillus, which can reproduce and reproduce at the oil reservoir temperature of 60°C. 2 PO 4 4g / L, K 2 HPO 4 1g / L, NaNO 3 1g / L, MgSO 4 0.4g / L, pH 7.0-7.2. , the biopolymer content produced is 0.05% (w / v), the viscosity is 2000mPa·s; the bacterial cell content in the fermentation broth is 0.05% (w / v).

[0030] The mass percentage of scleroglucan in the biopolymer crosslinking system slug is 0.1% and the composition of crosslinking agent, and the mass percentage of sodium dichromate in the crosslinking agent is 0.4%, and the mass percent of sodium hydrosulfate The percentage content is 0.2%. Two cross-linking systems with the same volume, one of which was simulated formation adsorption shear through the sand bed, was then placed under the same stability for cross-linking experiments,...

Embodiment 3

[0040] The bio-slug consists of living microorganisms that produce biopolymers and their fermentation products, biopolymers, and fermented nutrients. The living microorganism is the polymer-producing Sphingomonas that can reproduce at 40°C oil reservoir temperature, and its strain is 38g / L of sucrose, 1.6g / L of peptone, and 0.6g / L of beef extract in the fermentation nutrient. L, K 2 HPO 4 0.4g / L, fermented in the environment of NaCl0.1g / L, the biopolymer content produced is 3% (w / v), adding scleroglucan 2% (w / v), the viscosity is 7000mPa·s; The bacterial cell content is 10% (w / v).

[0041] The mass percent content of scleroglucan in the biopolymer crosslinking system slug is 5% and the composition of crosslinking agent, and the mass percent composition of sodium dichromate in the crosslinking agent is 1%, and the mass percent content of sodium hydrosulfate The percentage content is 1%.

[0042] The chemical polymer crosslinking system slug is composed of polyacrylamide wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com