Polymer composite with plasticity, ordered mesoporous polymer of multi-level structure and ordered mesoporous carbon material

A polymer and plastic technology, applied in the field of materials, to achieve the effect of simple equipment requirements, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

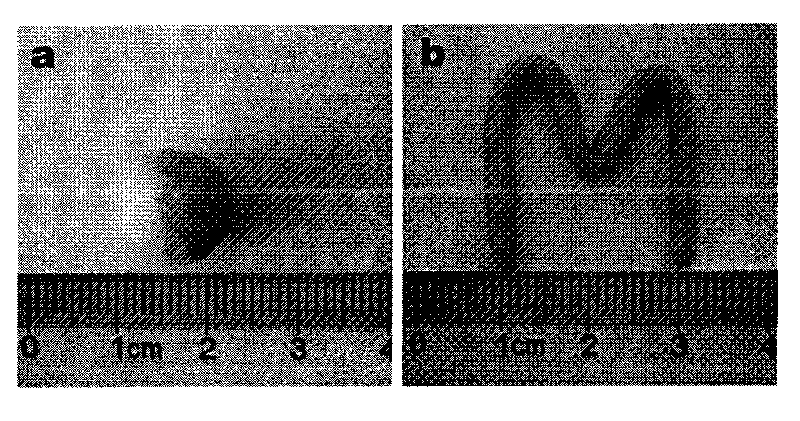

[0045] Add 3.0g (20wt%) resole ethanol solution to 4ml ethanol transparent solution containing 0.16g F127 and 1.25g 25R4, stir at 20-40°C for 1-2d to cause self-assembly reaction to obtain a transparent solution. The solution is transferred to a petri dish, volatilized at room temperature for 1-2 days, and then thermoset at 100°C for 24 hours to obtain a plastic polymer composite.

[0046] The scraped polymer compound with plasticity is molded into capital letter "M", and it is protected by nitrogen atmosphere and calcined at 350°C for 5 hours to remove surfactants to obtain ordered mesoporous polymer with hierarchical structure; Protected and carbonized at a high temperature of 600°C for 240 minutes to obtain an ordered mesoporous carbon material with a hierarchical structure whose shape is still a capital letter "M". The heating rate is 1~5°C / min during roasting to remove the surfactant and high temperature carbonization.

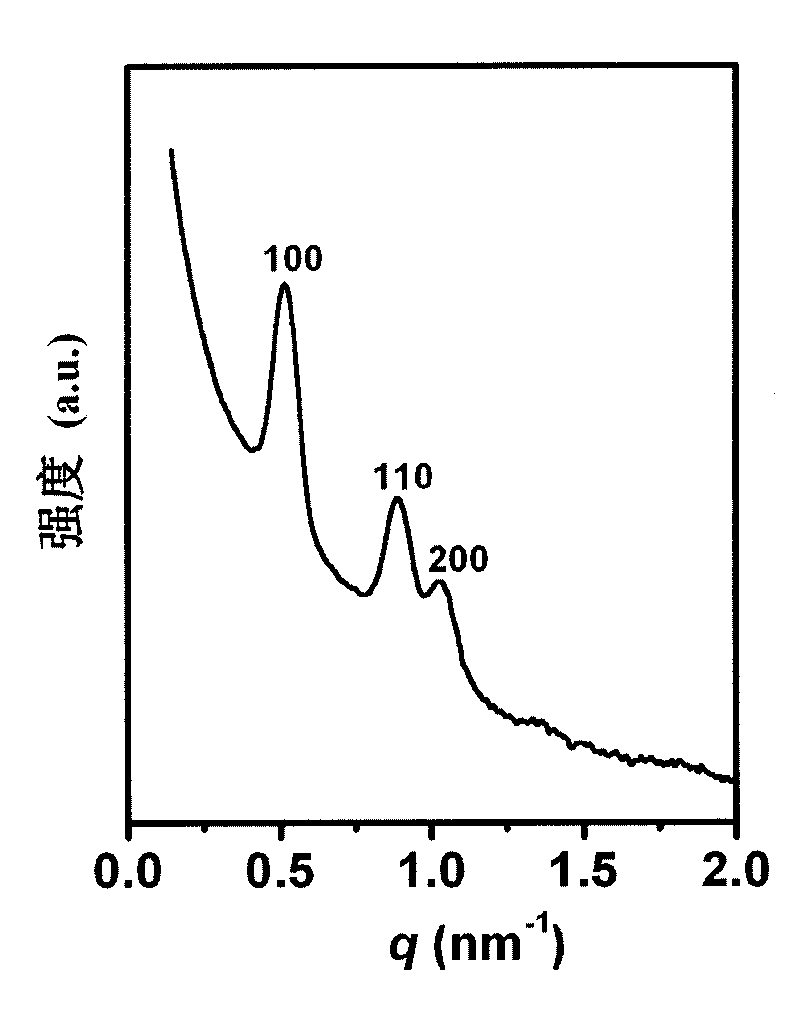

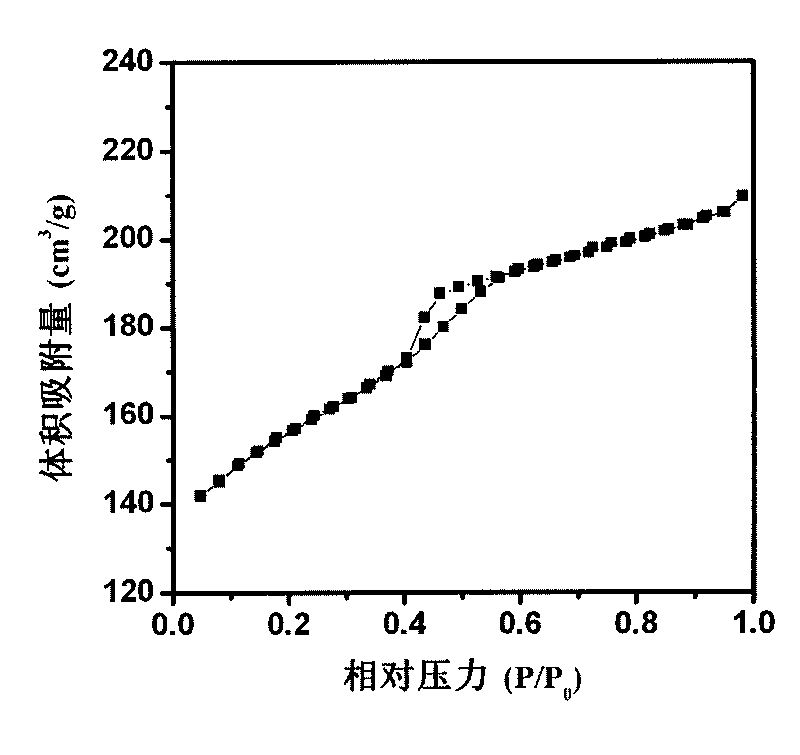

[0047] The SAXS spectrum proves that the pore space sym...

Embodiment 2

[0049] Add 3.0g (20wt%) melamine resin ethanol solution to 4ml of transparent ethanol solution containing 0.16g F127 and 2.5g 25R4, stir at 30-40°C for 1-2h to cause self-assembly reaction to obtain a transparent solution. Transfer the solution to a petri dish, volatilize at room temperature for 1-2 days to remove the solvent, and then heat-solidify at 100°C for 12 hours to obtain a plastic polymer composite.

[0050] The scraped polymer composite with plasticity is protected by a nitrogen atmosphere and calcined at 450°C for 5 hours to remove the surfactant to obtain an ordered mesoporous polymer with a hierarchical structure; then protected by a nitrogen atmosphere and carbonized at 600°C for 480 minutes to obtain Ordered mesoporous carbon material with hierarchical structure.

Embodiment 3

[0052] Add 3.0g (20wt%) resole phenolic resin ether solution to 4ml of a transparent ether solution containing 0.16g F127 and 2.5g 25R4, and stir at 30-40°C for 4-5h to cause self-assembly reaction to obtain a transparent solution. Transfer the solution to a petri dish, volatilize at room temperature for 1-2 days to remove the solvent, and then heat-solidify at 120°C for 24 hours to obtain a plastic polymer composite.

[0053] The scraped polymer compound with plasticity is protected by argon atmosphere and calcined at 350°C for 5h to remove the surfactant to obtain an ordered mesoporous polymer with a hierarchical structure; then it is protected by argon atmosphere and carbonized at 900°C for 240 minutes to obtain more Ordered mesoporous carbon material with hierarchical structure. The heating rate is 1~5°C / min during roasting to remove the surfactant and high temperature carbonization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com