Rotary type tubular tissue biological 3D printing device and method thereof

A tissue biology and 3D printing technology, applied in the field of tissue engineering technology and biological 3D printing, can solve the problems of easy collapse of printing length and difficult to form, and achieve the effect of controllable printing length, solving difficult forming and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

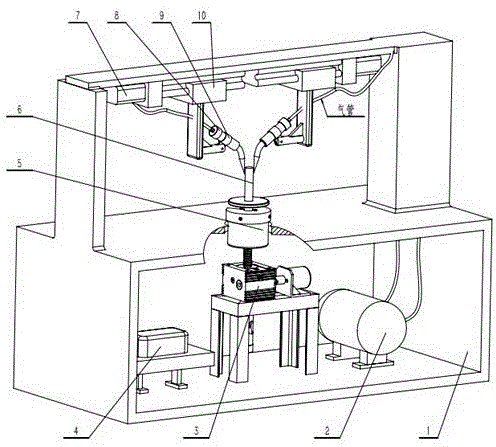

[0028] The specific structure, working principle and working process content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

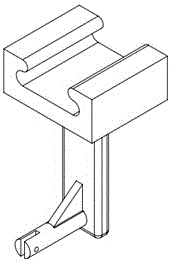

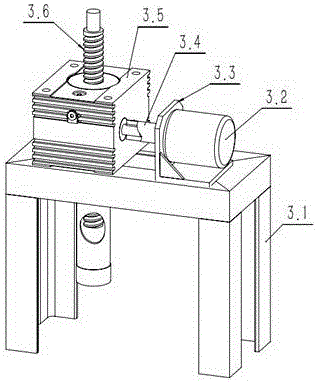

[0029] Such as Figure 1-4 As shown, a rotary tubular tissue biological 3D printing molding device includes a frame bed 1, an air source 2, a lifting mechanism assembly 3, a controller 4, a rotating connection tray assembly 5, a columnar bracket 6, and a nozzle drive assembly; The lower part of the lifting mechanism assembly 3 is installed and fixed with the inner lower plate of the frame bed body 1, and the upper part is connected with the lower part of the rotating connecting tray assembly 5, which can drive the rotating connecting tray assembly 5 to move up and down; the upper part of the rotating connecting tray assembly 5 is fixedly placed on a column Bracket 6, the middle part passes through the middle through hole of the table top of the frame bed body 1, and the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com