A casting method of an ultrafine high-nickel-content air tube

A technology of air tube and thin height, which is applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problems of difficult molding, and achieve the effect of fast solidification speed, easy operation and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

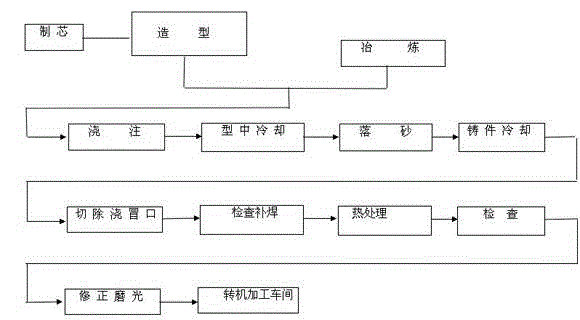

[0018] figure 1 It is a casting flowchart of the high-nickel air pipe of the present invention, adopting 4 steps of core making, moulding, pouring, and shakeout:

[0019] a. Core making: low-nitrogen high-strength coated sand is used. The strength of the coated sand is ≥3.4MPa, and the low gas emission is ≤14m / g. Cold iron is inlaid at the position of the clamping position, and the vent hole is set in the inner sand core, which can make the venting of the sand core in the mold very smooth, and the vent hole will not be blocked by molten iron, thus avoiding the appearance of porosity on the working surface and improving the The quality of the workpiece has increased the qualified rate of the product to more than 98%;

[0020] b. Modeling: After the coated sand core is combined and formed, the large-hole flow casting system technology is used, and the side riser is used to feed the shrinkage. The static pressure head during pouring is provided by the green mold sand:

[0021] ...

Embodiment 2

[0025] The casting method of high-nickel austenitic nodular cast iron automobile air pipe adopts four steps of core making, molding, pouring and shakeout. The process steps are:

[0026] a. Core making: low-nitrogen high-strength coated sand is used. The strength of the coated sand is ≥3.4MPa, and the low gas emission is ≤14m / g. The position of the card position is inlaid with cold iron.

[0027] b. Modeling: After the coated sand core is combined and formed, the large-hole flow casting system technology is used, and the side riser is used to feed the shrinkage. The static pressure head during pouring is provided by the green mold sand:

[0028] c. Pouring: adopt the low-temperature rapid pouring process, control the pouring temperature at 1560°C±10°C, control the pouring speed of molten iron at 70~100Kg / min, control the temperature of the final pouring box at no less than 1540°C, and use the pouring process to control the product The method of pouring by flipping 90 degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com