Technology for forming maintenance-free lead-acid battery pole plates

A lead-acid battery, maintenance-free technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of easy corrosion of the grid, low production efficiency, broken ribs, etc., and achieves good safety protection performance, high production efficiency, and thickness tolerance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

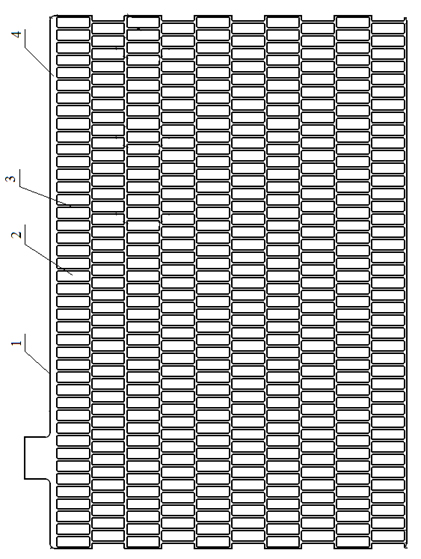

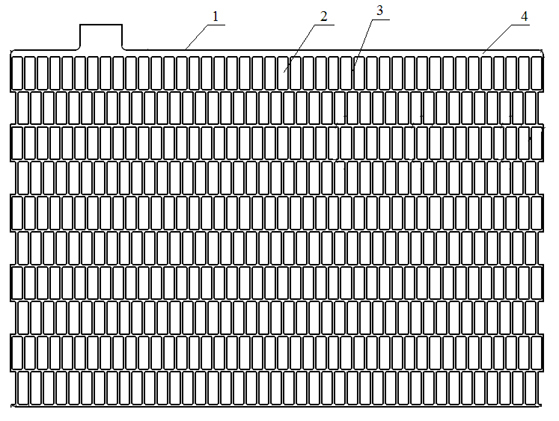

[0009] Such as figure 1 As shown, the plate is formed according to the following specific steps: first, the alloy lead liquid is heated and melted in a furnace; second, the alloy lead liquid is cast into a lead belt by a belt casting machine; third, the lead belt is cast by a winding machine Winding up; fourth, send the lead strip into the punching machine for stamping to form a grid strip 1, the middle of the grid strip 1 is a uniform rectangular hole 2, the ribs 3 are between the holes, and the two sides of the grid strip are cut pole ears The corner lead strip 4 used; the fifth, the grid strip is wound by a winding machine; the sixth, the grid strip is coated with a plate coating machine and divided by a splitting mold to form a pole plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com