Method of forming high-precision bright flat steel by carrying out cold rolling on wire

A high-precision, wire rod technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of inability to coil, large waste of drawing heads, poor surface finish, etc., and achieve narrow width and thickness tolerances, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

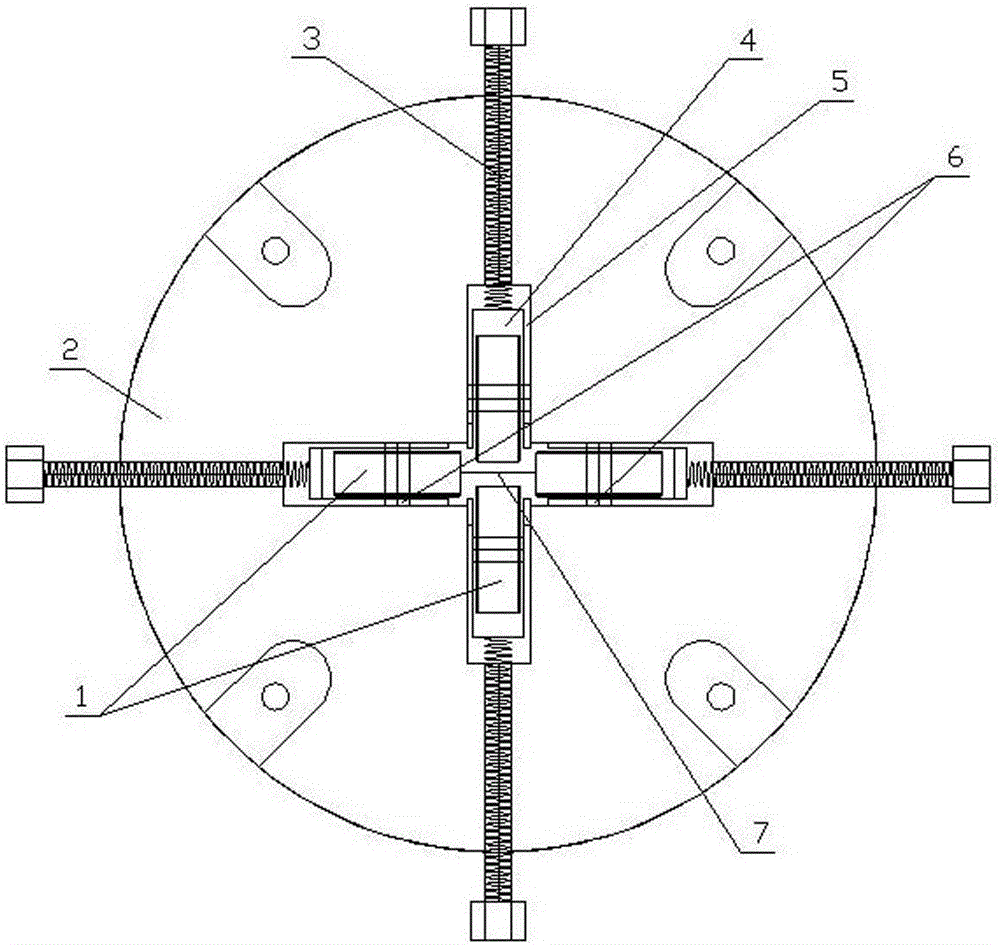

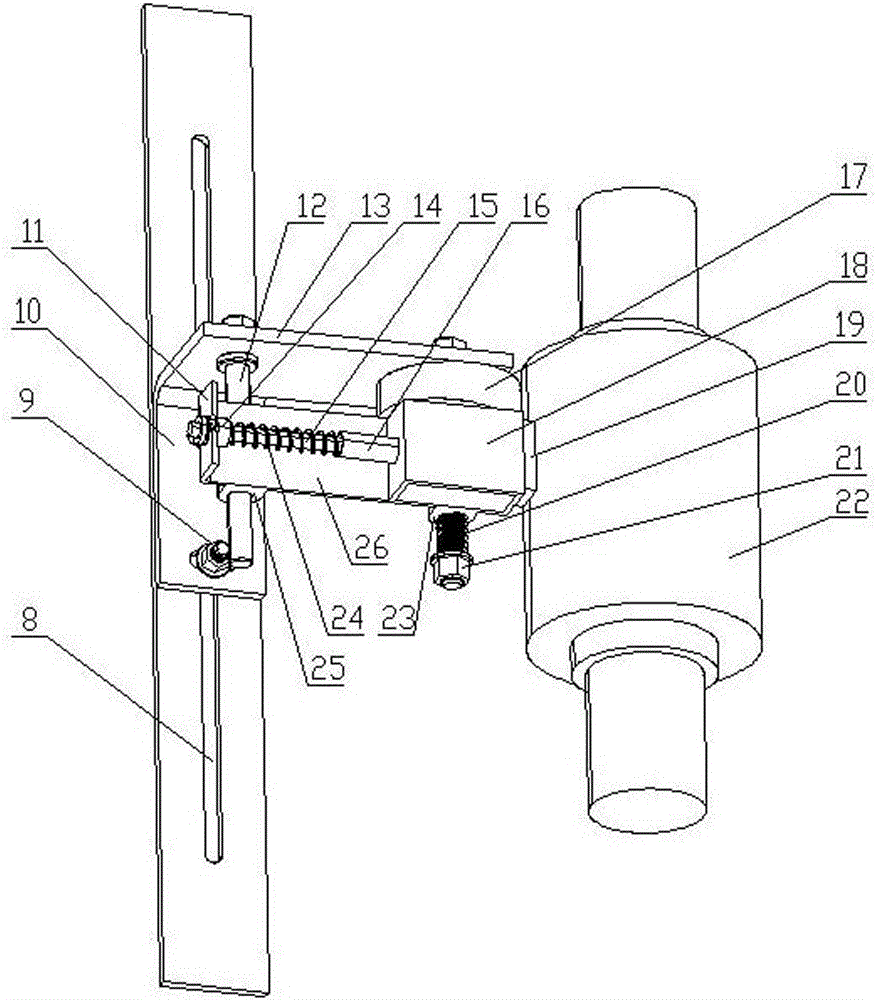

Image

Examples

Embodiment 1

[0030] First select the Q195 wire coil round steel of ∮8, and set it aside.

[0031] Then, use a hydrochloric acid solution with a concentration of 15% and a temperature of 10°C to pickle the wire, disc, and round steel for 15 minutes.

[0032] After that, immerse the pickled wire, coil and round steel in an alkali solution with a concentration of 20% and a temperature of 10° C. for 3 minutes.

[0033] Afterwards, rinse the neutralized wire rod and round steel for 3 minutes with a high-pressure water gun.

[0034] Afterwards, place the washed wire coil and round steel on the unwinding rack, and use the conveying roller to send one end of the wire coil and round steel into the pre-calibration machine and cleaning machine in turn, and wash off the residue on the wire coil and round steel after pre-calibration Impurities.

[0035] Afterwards, use the first to fifth five-tandem rolling mills to carry out pre-rolling on the pre-calibrated and impurity-removed wire rods and round ...

Embodiment 2

[0045] First select the Q195 wire coil round steel of ∮16, and set it aside.

[0046] Then, use a hydrochloric acid solution with a concentration of 23% and a temperature of 18°C to pickle the wire, disc, and round steel for 17 minutes.

[0047] Afterwards, immerse the pickled wire, coil, and round steel in an alkali solution with a concentration of 25% and a temperature of 18° C. for 4 minutes.

[0048] Afterwards, use a high-pressure water gun to flush the neutralized wire rod round steel for 4 minutes.

[0049] Afterwards, place the washed wire coil and round steel on the unwinding rack, and use the conveying roller to send one end of the wire coil and round steel into the pre-calibration machine and cleaning machine in turn, and wash off the residue on the wire coil and round steel after pre-calibration Impurities.

[0050] After that, use the first to fifth five-tandem rolling mills to carry out pre-rolling on the pre-calibrated and impurity-removed wire rods and roun...

Embodiment 3

[0060] First select the Q195 wire coil round steel of ∮ 30 for later use.

[0061] Then, use a hydrochloric acid solution with a concentration of 30% and a temperature of 30°C to pickle the wire, disc, and round steel for 20 minutes.

[0062] After that, immerse the pickled wire, coil and round steel in an alkali solution with a concentration of 30% and a temperature of 30° C. for 5 minutes.

[0063] Afterwards, rinse the neutralized wire rod and round steel for 5 minutes with a high-pressure water gun.

[0064] Afterwards, place the washed wire coil and round steel on the unwinding rack, and use the conveying roller to send one end of the wire coil and round steel into the pre-calibration machine and cleaning machine in turn, and wash off the residue on the wire coil and round steel after pre-calibration Impurities.

[0065] After that, use the first to fifth five-tandem rolling mills to carry out pre-rolling on the pre-calibrated and impurity-removed wire rods and round st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com