Preparation method and expansion preparation device of soil heavy metal repair agent

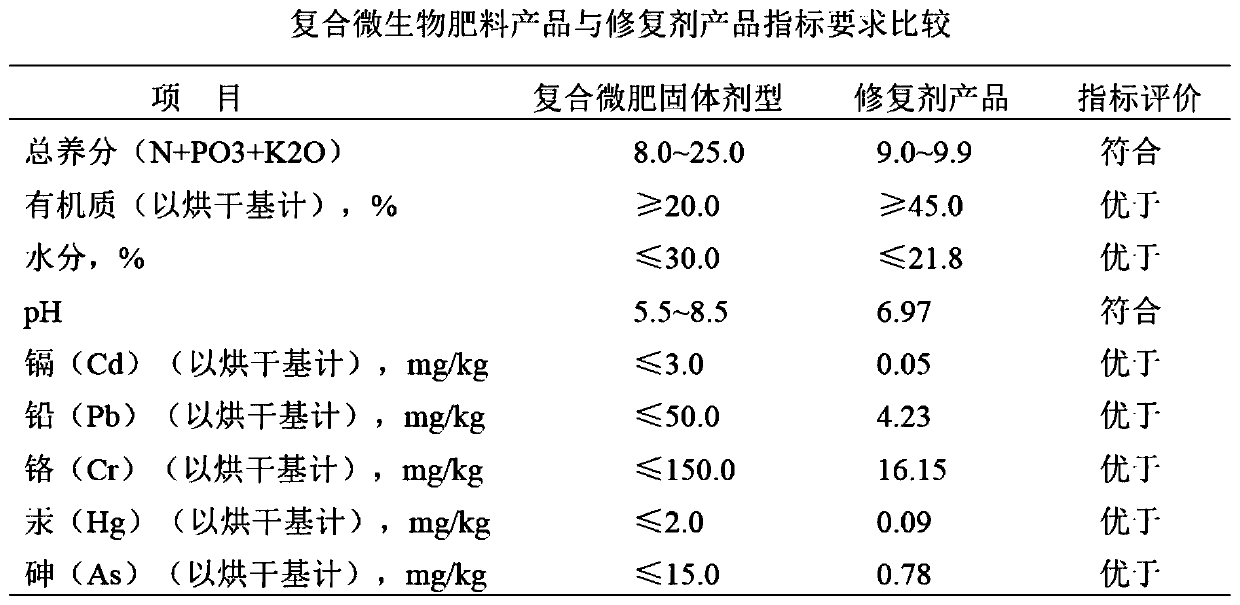

A technology for preparing devices and heavy metals, applied in fertilization devices, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as poor puffing effect, increase soil fertility, and complex puffing process, and achieve stable effects, increase soil fertility, and technology. Implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

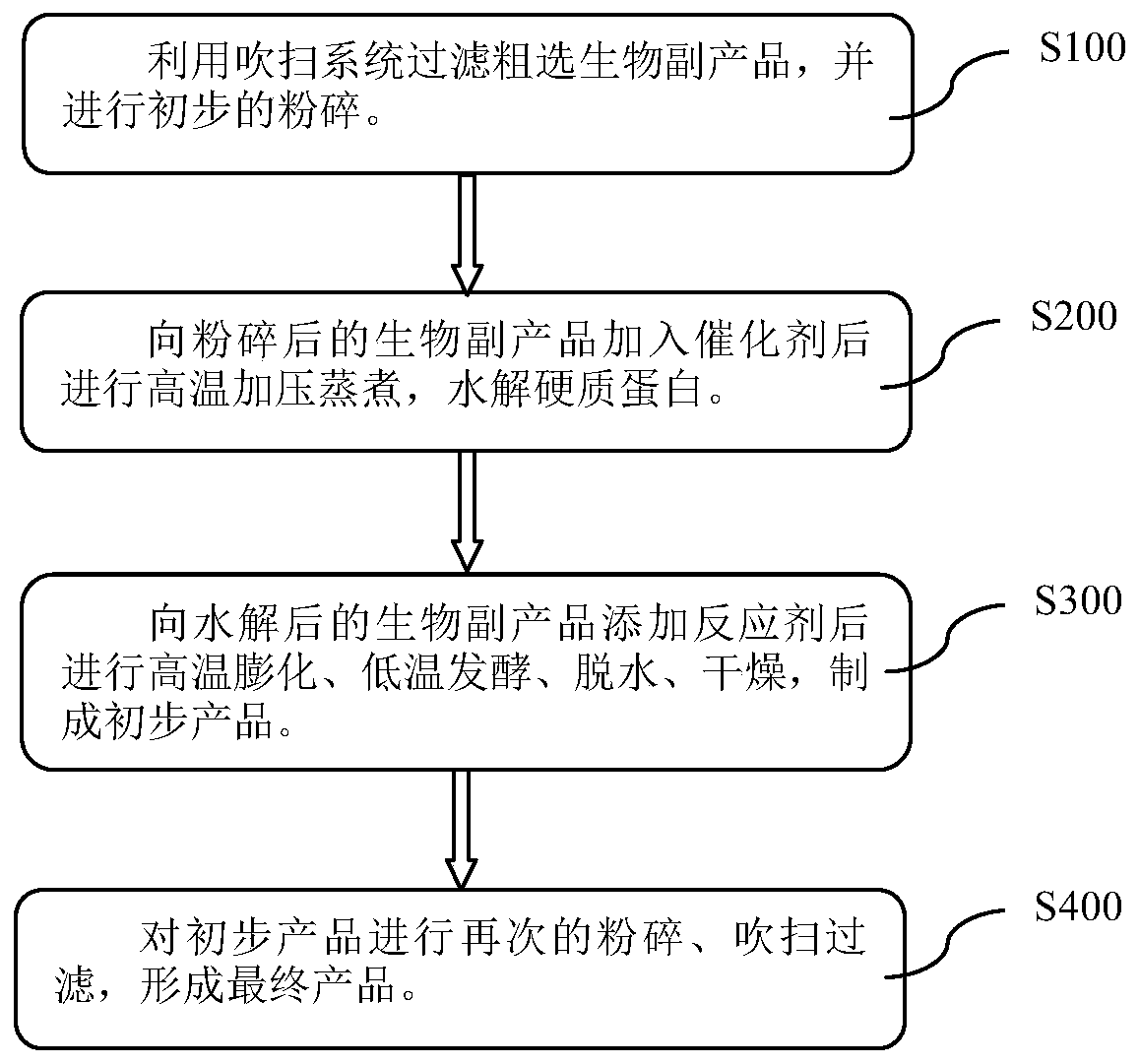

[0039] like figure 1 and figure 2 Shown, the present invention provides a kind of preparation method of soil heavy metal remediation agent, it is characterized in that, comprises steps:

[0040] S100, using the purge system to filter the rough selection of biological by-products, and perform preliminary crushing;

[0041] S200, adding a catalyst to the pulverized biological by-products, and then performing high-temperature and pressure cooking to hydrolyze hard protein;

[0042] S300, adding a reactant to the hydrolyzed biological by-products, and then performing high-temperature puffing, low-temperature fermentation, dehydration, and drying to make a preliminary product;

[0043] S400, crushing, purging and filtering the preliminary product again to form a final product.

[0044] The biological by-products include feathers, hoof shells, hair and horn feathers of poultry or livestock, epidermis and viscera of slaughtered poultry or livestock, and some plant fruits with hig...

Embodiment 2

[0084] The present invention also provides an expansion device for producing a restoration agent, specifically a soil heavy metal restoration agent expansion preparation device, comprising a hyperbaric cabin 1 provided with a feed inlet 11 and a discharge outlet 12, and a hyperbaric cabin installed on the hyperbaric cabin The material flat pressure mechanism 2 in 1, the fluidized transfer bed 3 is arranged between the material flat pressure mechanism 2 and the feed port 11, and the seal connection between the feed port 11 and the fluidized transfer bed 2 makes the feed port 11 is incompletely isolated from the inside of the hyperbaric cabin 1, which facilitates the formation of air pressure difference;

[0085] The outlet 12 is connected with the expansion chamber 4, the side wall of the hyperbaric cabin body 1 at the bottom is connected with the steam generating device 6 through the air supply pipeline 5, and the top of the hyperbaric cabin body 1 is connected to the steam gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com