Roll bending forming die and forming method of large-curvature semi-arc-shaped pipe orifice reinforcing part

A molding method and molding die technology, applied in the field of aircraft manufacturing, can solve the problems of difficult reinforcement, complex production process, and high manufacturing cost, and achieve the effects of stable product quality, fewer molds, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

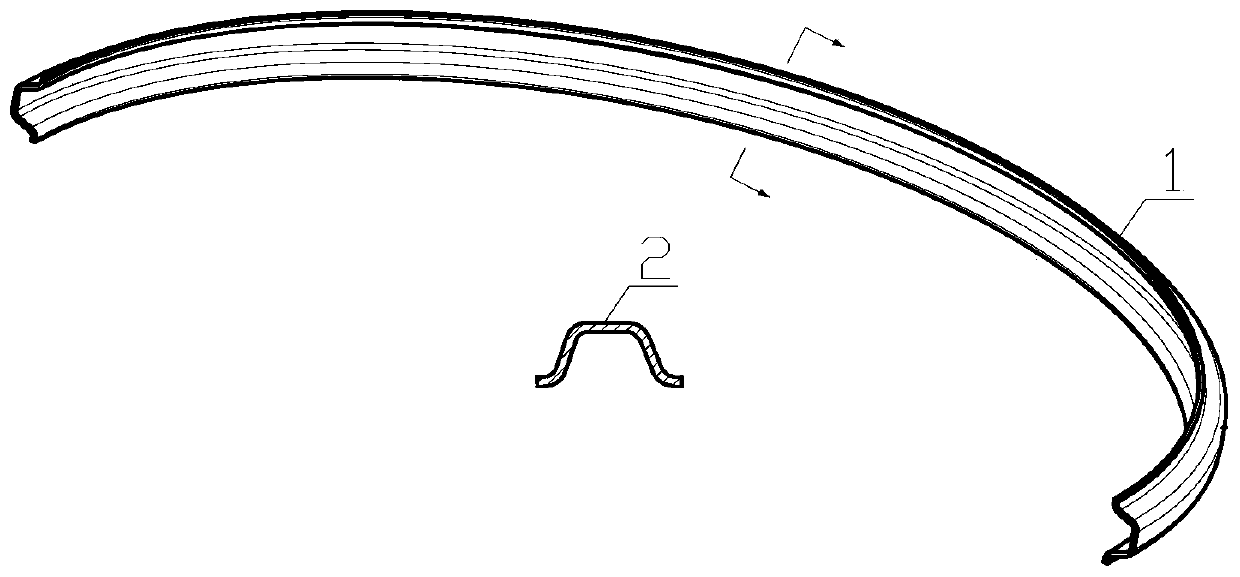

[0023] Referring to the accompanying drawings, the aircraft parts provided by the embodiment are as figure 1 As shown, the part 1 is a large-curvature high-strength alloy sheet metal part with a trapezoidal notch 2 in cross-section, which is used to strengthen the strength and sealing performance of the pipe fittings. The biggest problem of forming with the existing technology is that the stamping forming is unstable and wrinkled Serious, but manual molding is difficult to make the material yield, it is highly dependent on the technical level of the workers, the surface quality of the parts is poor, and it is impossible to shape the structure of the overall arc more than 1 / 2 circle.

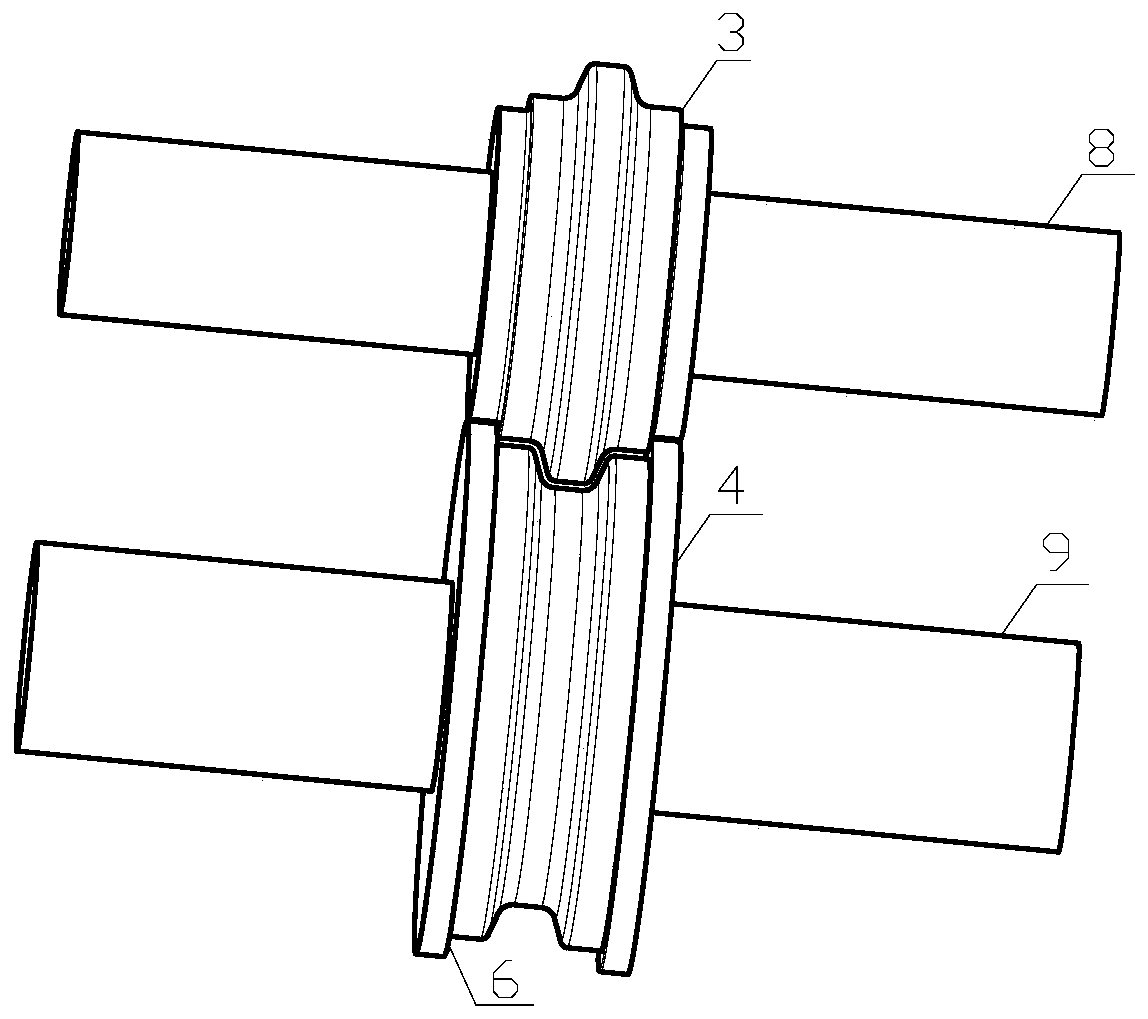

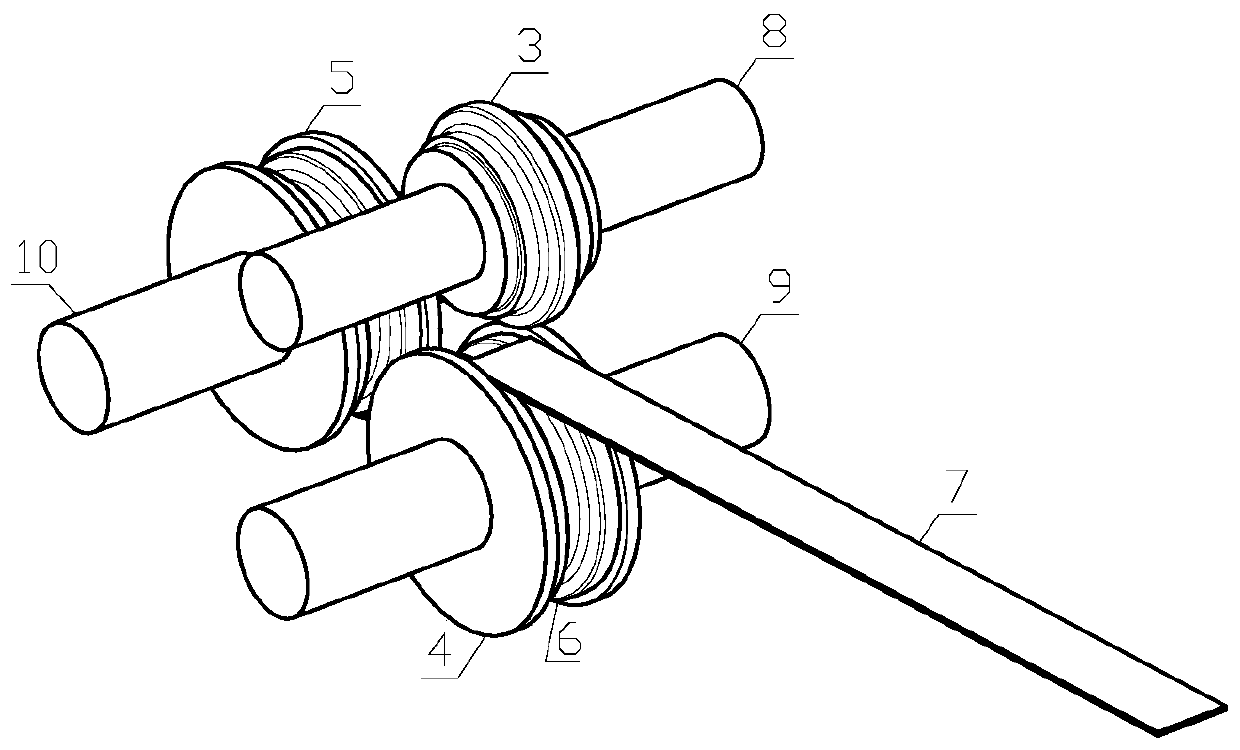

[0024] The molding die that this application proposes is as figure 2  ̄ image 3 As shown, the molding die contains a molding cam 3, a molding concave wheel 4 and a driven concave wheel 5. The longitudinal outer contour section of the molding cam 3 matches the internal shape of the trapezoidal n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com