Patents

Literature

218 results about "Rolleron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rolleron is a type of aileron used for rockets, placed at the trailing end of each fin, and used for passive stabilization against rotation. Inherent to the rolleron is a metal wheel with notches along the circumference. On one side, the notches protrude into the airflow. During flight, this will spin the wheels up to a substantial speed. The wheels then act as gyroscopes. Any tendency of the rocket to rotate around its major axis will be counteracted by the rollerons: the gyroscopic precession acts to move the rolleron in the opposite direction to the rotation.

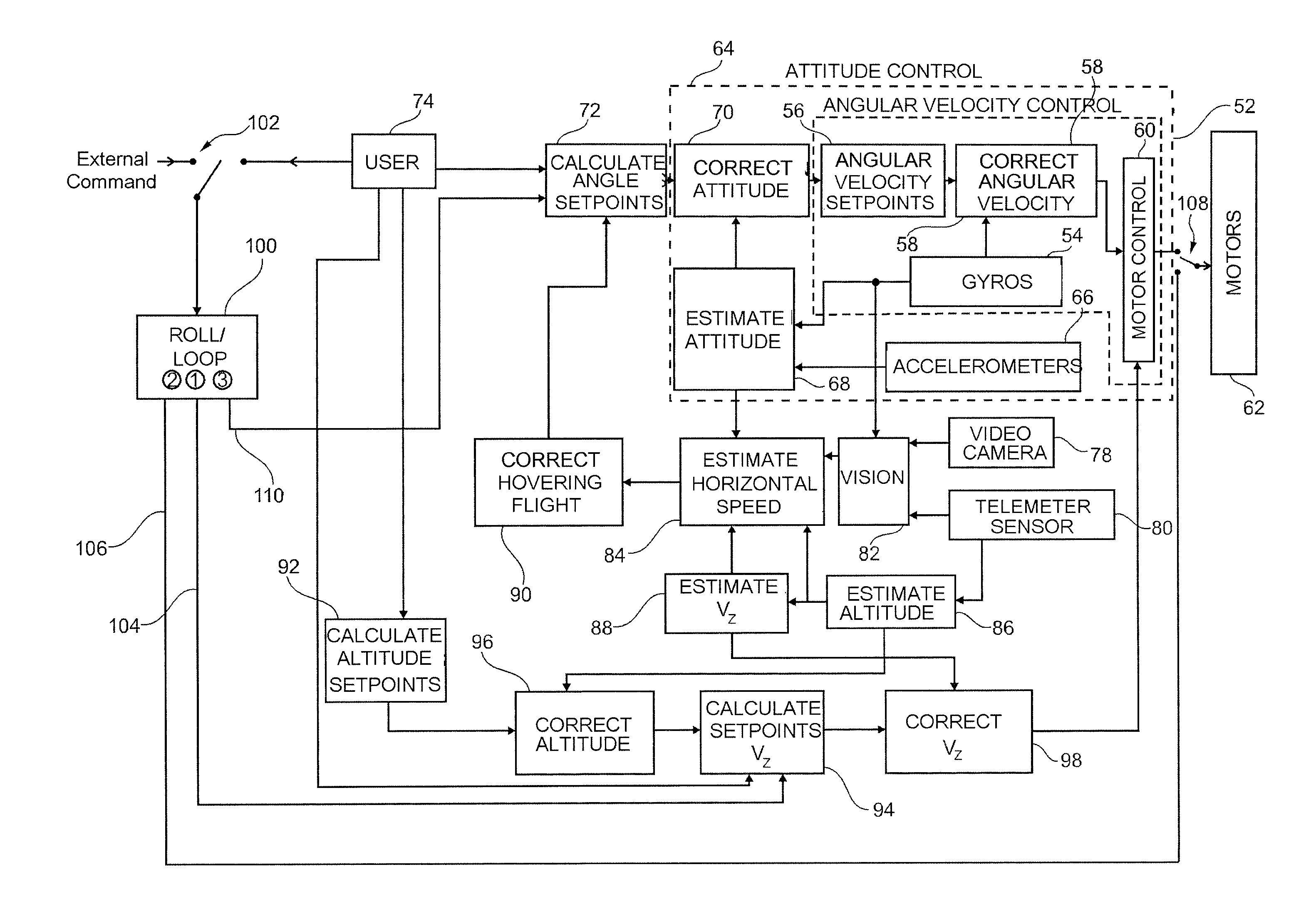

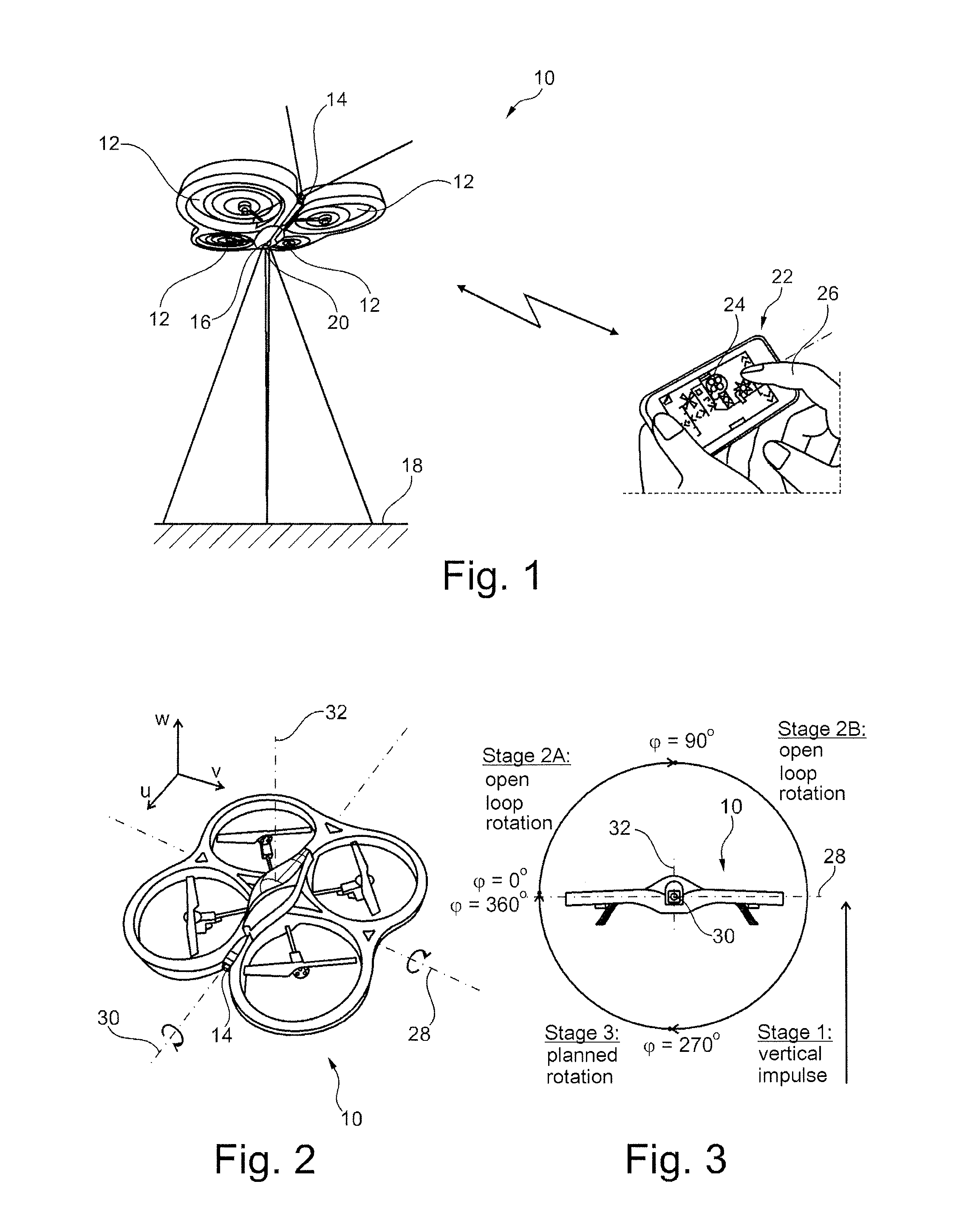

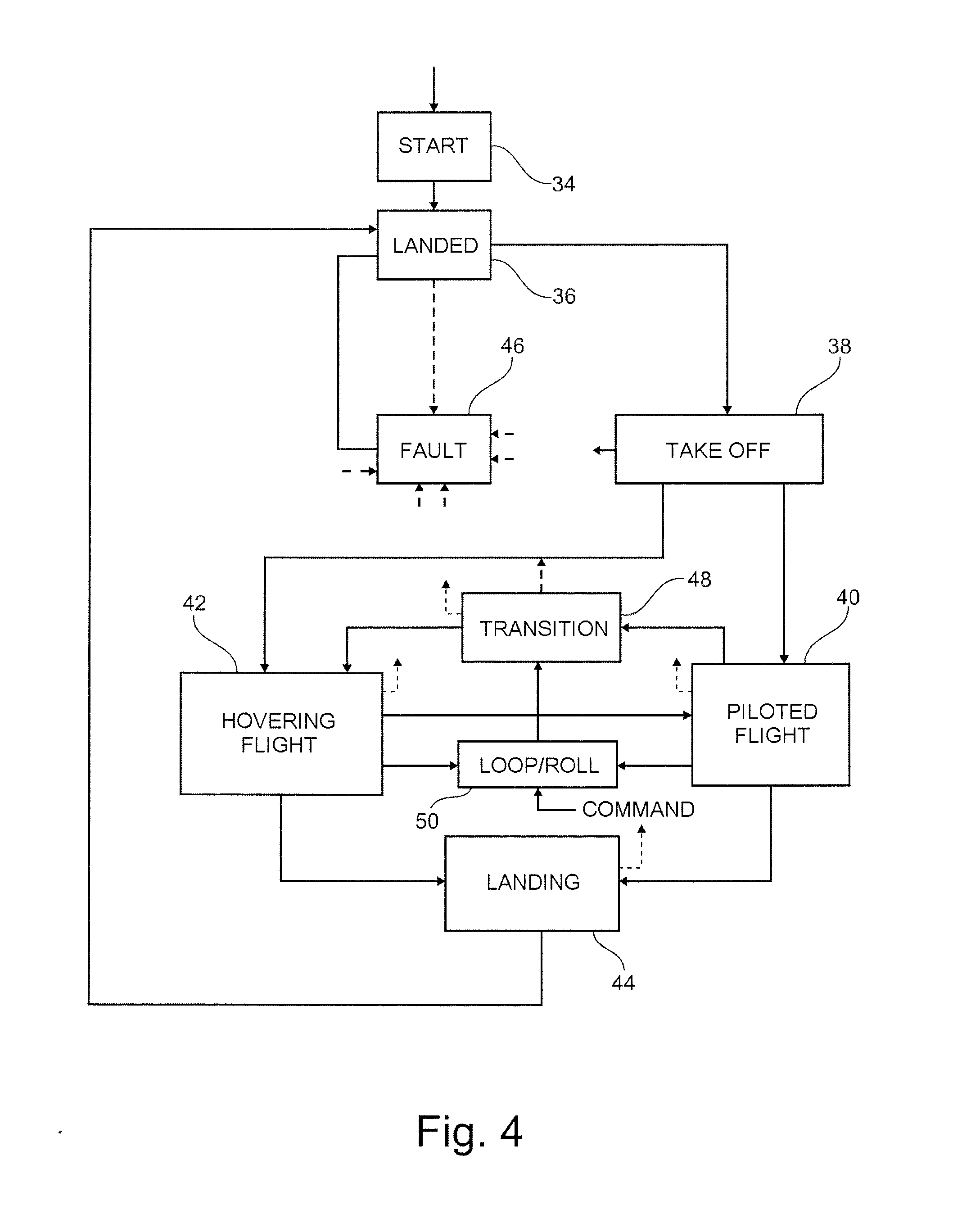

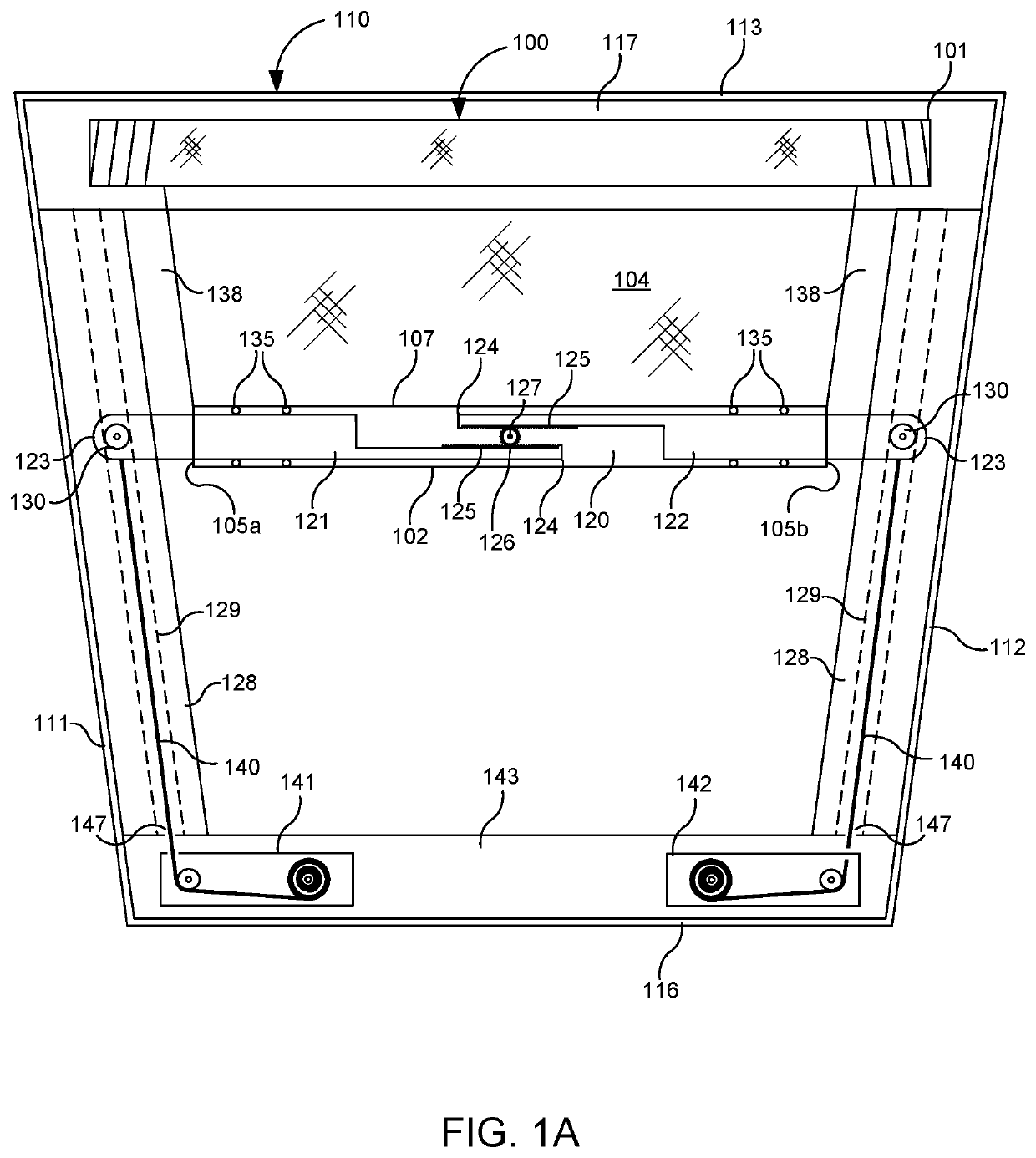

Method of dynamically controlling the attitude of a drone in order to execute a flip type maneuver automatically

InactiveUS20130006448A1Neat and accuratePropellersDigital data processing detailsRotational axisElectric machinery

This method controls the drone in order to flip through a complete turn about its roll axis or its pitching axis. It comprises the steps of: a) controlling its motors simultaneously so as to impart a prior upward vertical thrust impulse to the drone; b) applying different and non-servo-controlled commands to the motors so as to produce rotation of the drone about the axis of rotation of the flip, from an initial angular position to a predetermined intermediate angular position; and then c) applying individual control to the motors, servo-controlled to a reference target trajectory, so as to finish off the rotation of the drone through one complete turn about the axis of rotation, progressively from the intermediate angular position with a non-zero angular velocity to a final angular position with a zero angular velocity.

Owner:PARROT

Variable valve lift mechanism of engine

The invention discloses a variable valve lift mechanism of an engine. The variable valve lift mechanism comprises a cam arranged on a cam shaft, a hydraulic tappet positioned and mounted in a cylinder cover, a swinging arm of which one end is supported on the hydraulic tappet, a valve connected with the other end of the swinging arm, a swinging arm roller arranged in the middle of the swinging arm, a driving device, a slide bar which is connected with the driving device and is driven by the driving device to slide, a bar-shaped sliding chute component which is positioned and mounted in the cylinder cover and is matched with the slide bar, and a rocker arm located between the cam and the swinging arm, wherein the rocker arm consists of a supporting seat, a roller shaft and a rocker arm roller; one end of the supporting seat sleeves the slide bar, and the supporting seat can rotate relative to the slide bar; the roller bearing is positioned and mounted at the other end of the supporting seat; the rocker arm roller is connected to the roller shaft, and can rotate in the supporting seat relative to the roller shaft; the rocker arm roller is matched with the cam and the swinging arm roller, and the rotation of the cam is transferred to the swinging arm roller. Through the adoption of the mechanism, the lift of the valve can be changed, and more ideal gas distribution is achieved. At the same time, the structure is simplified, the reliability is improved, and the cost is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

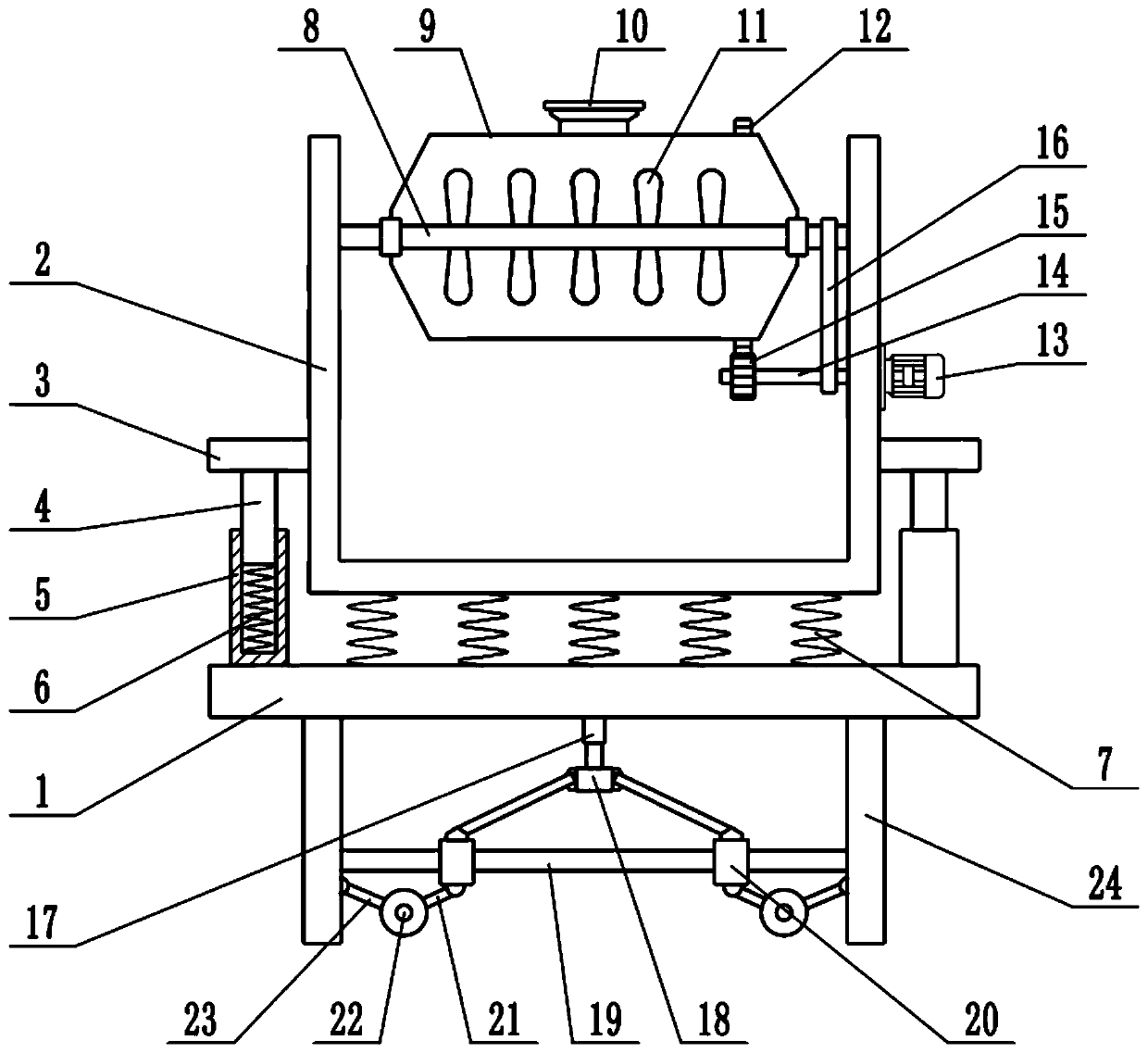

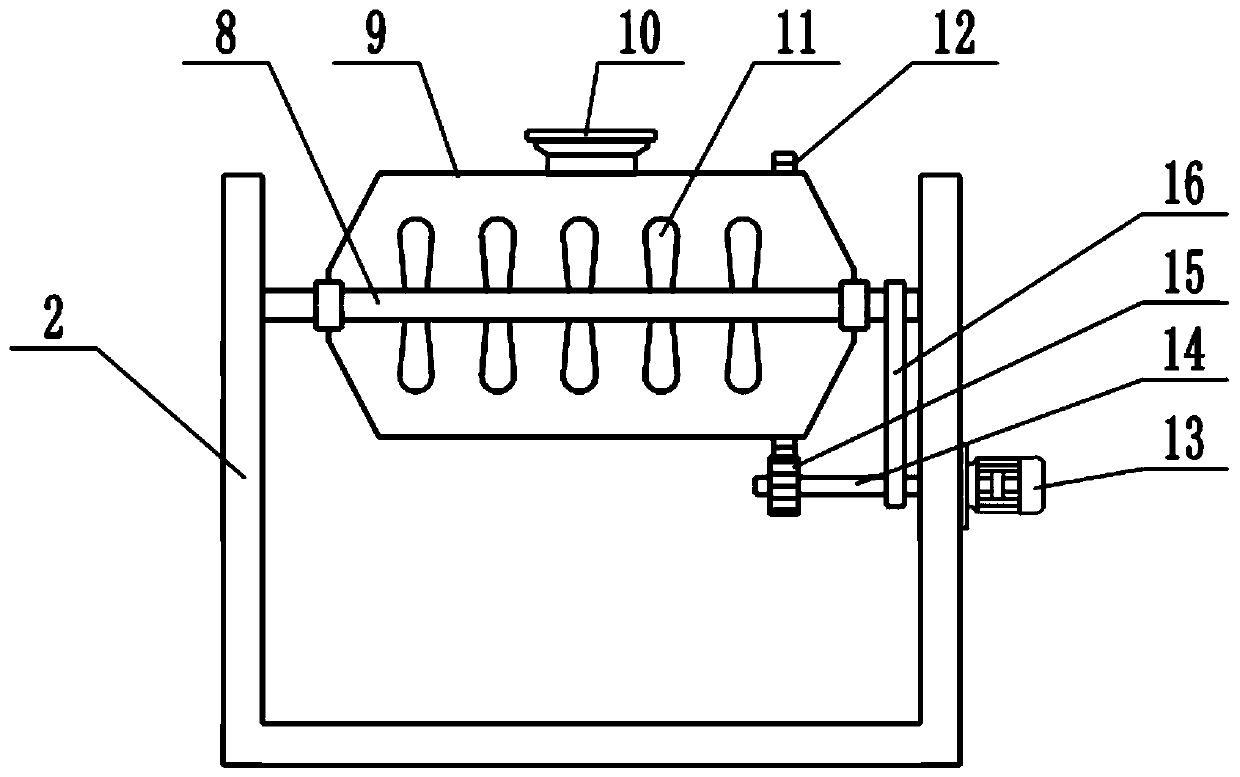

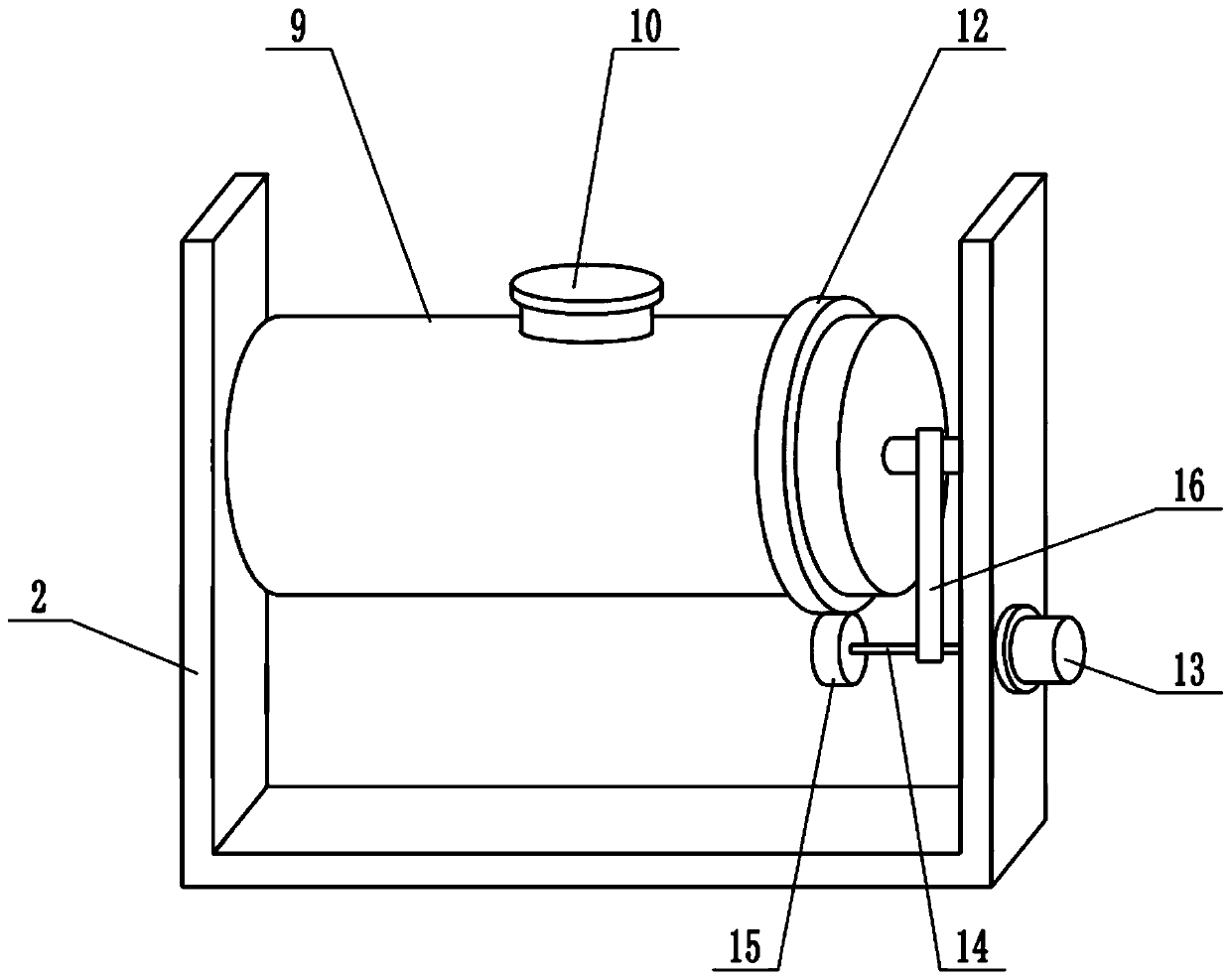

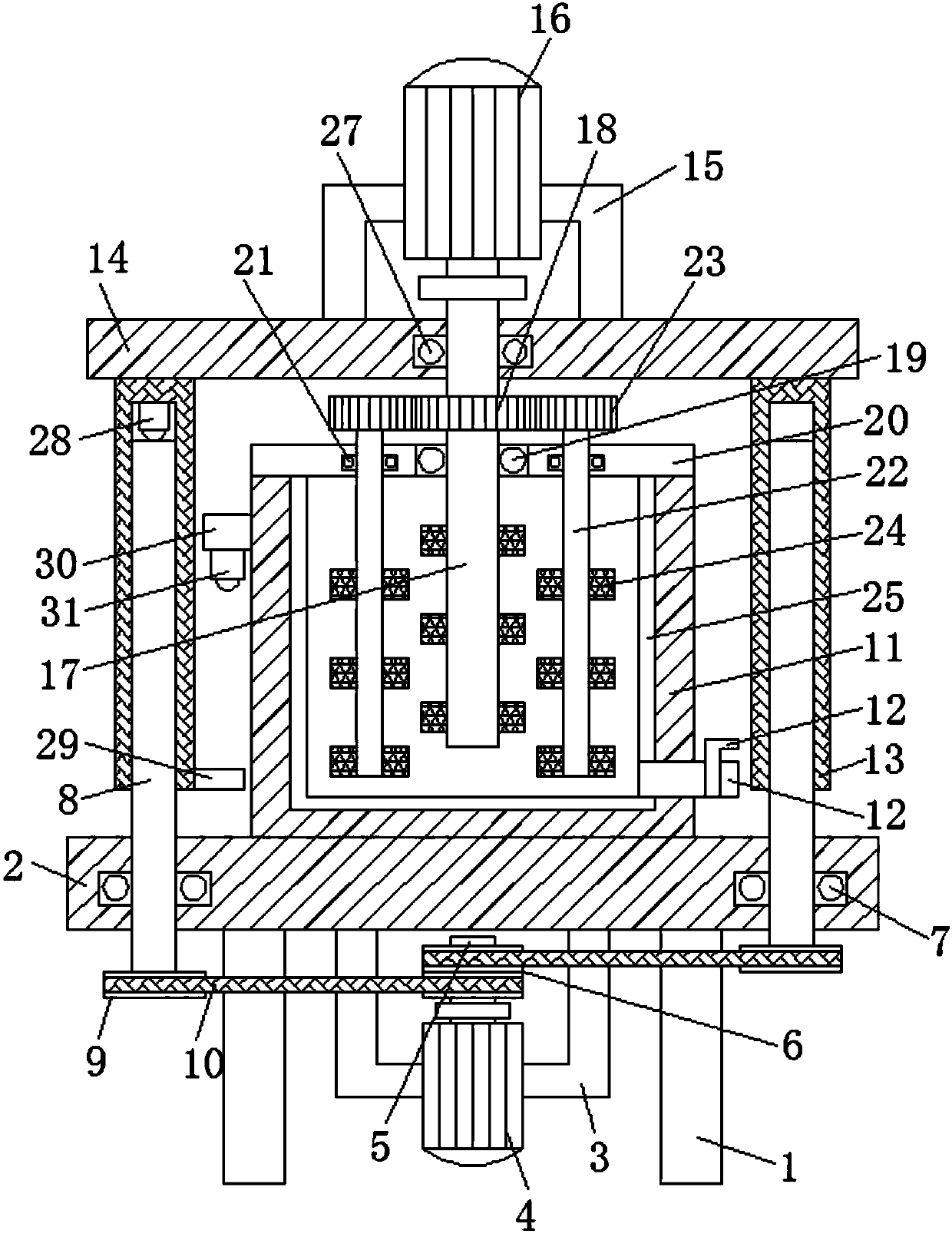

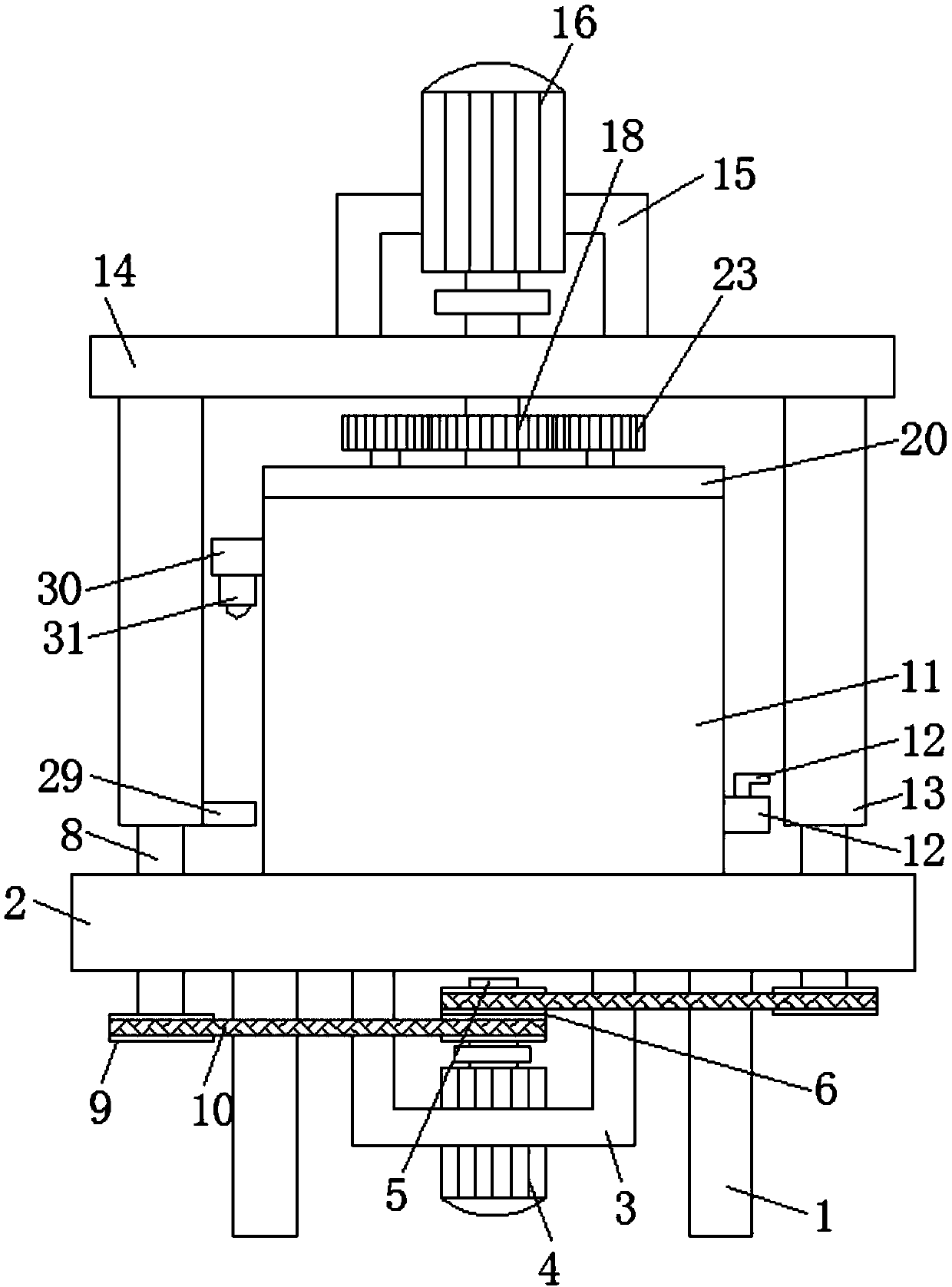

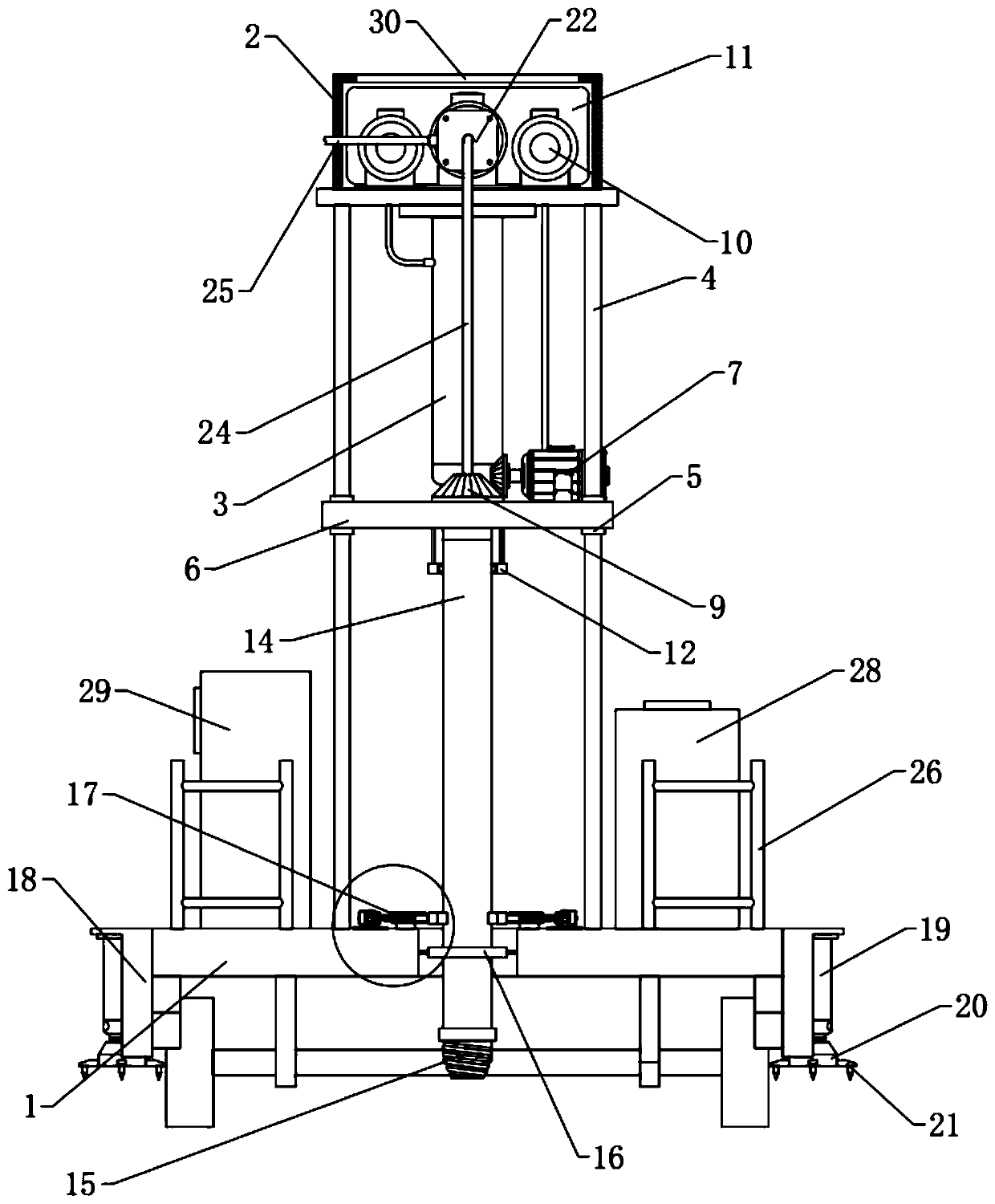

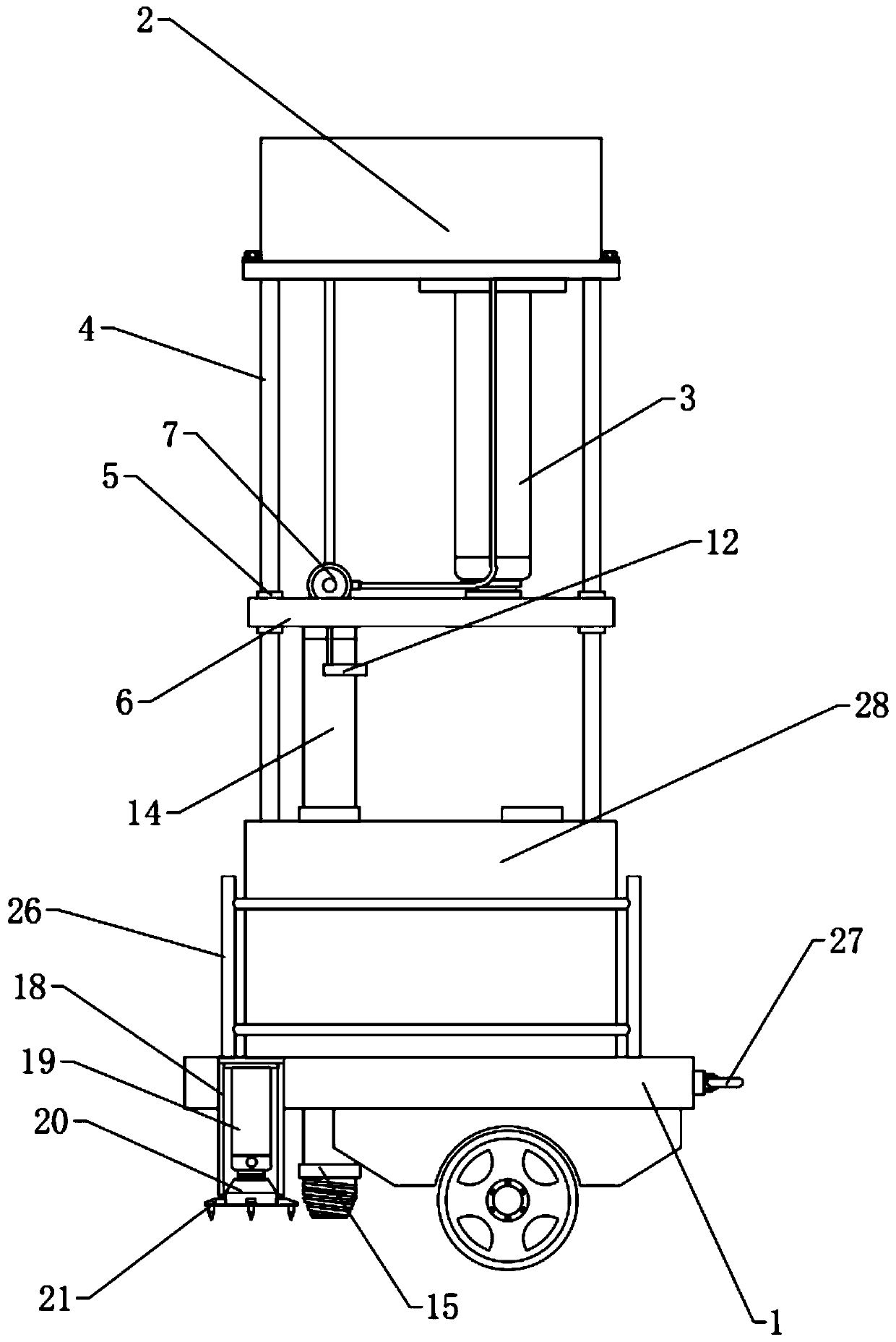

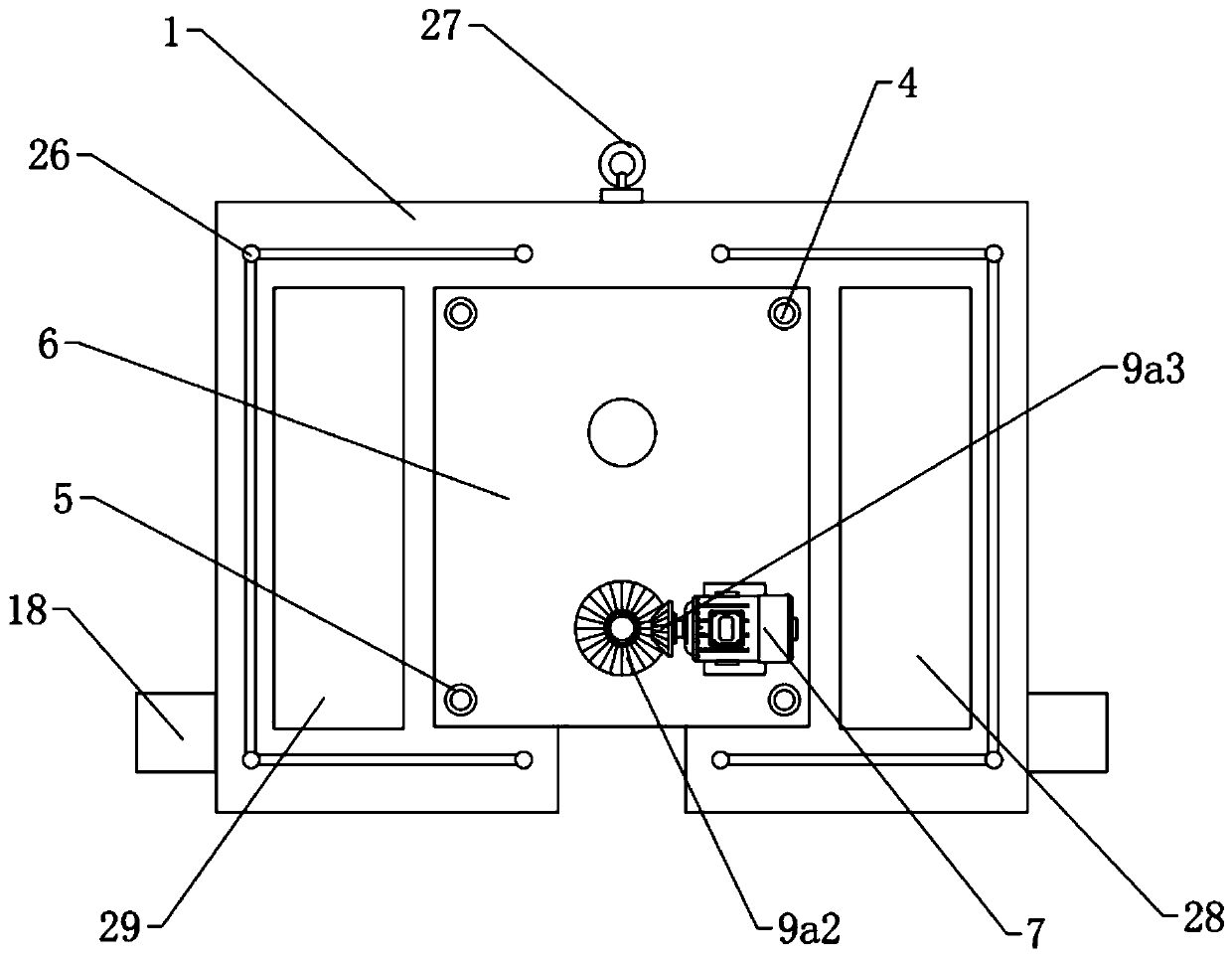

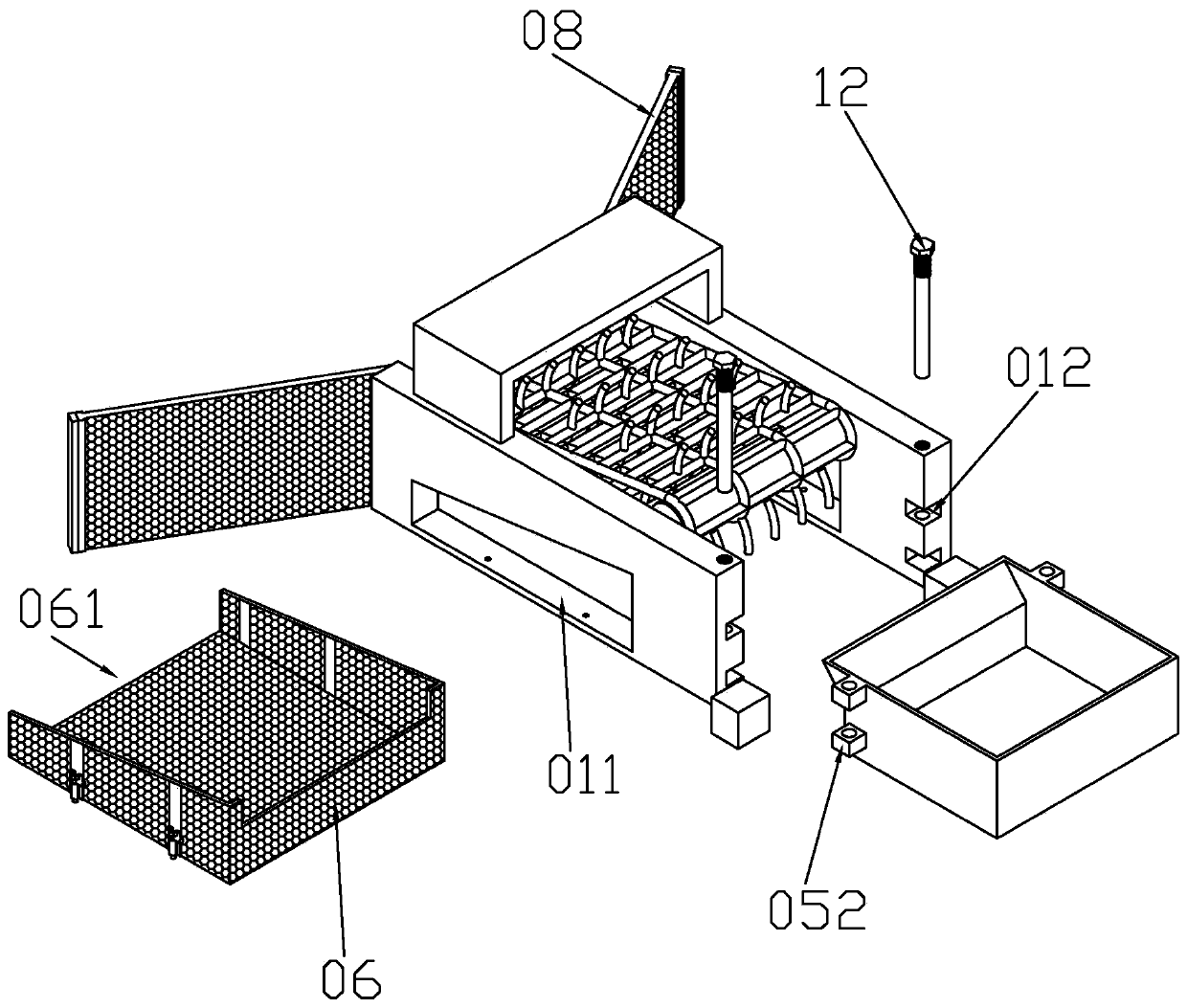

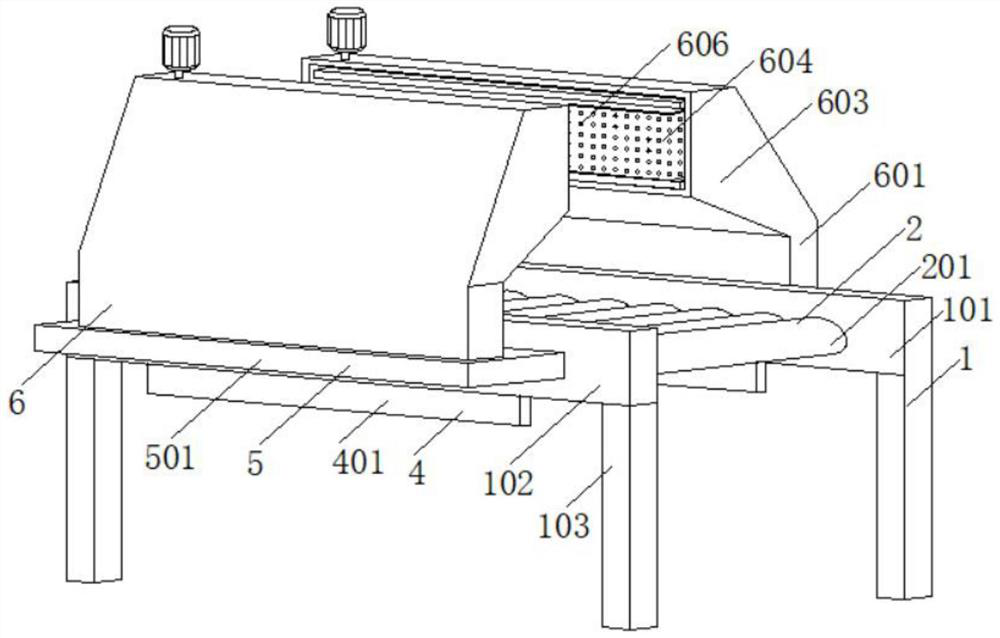

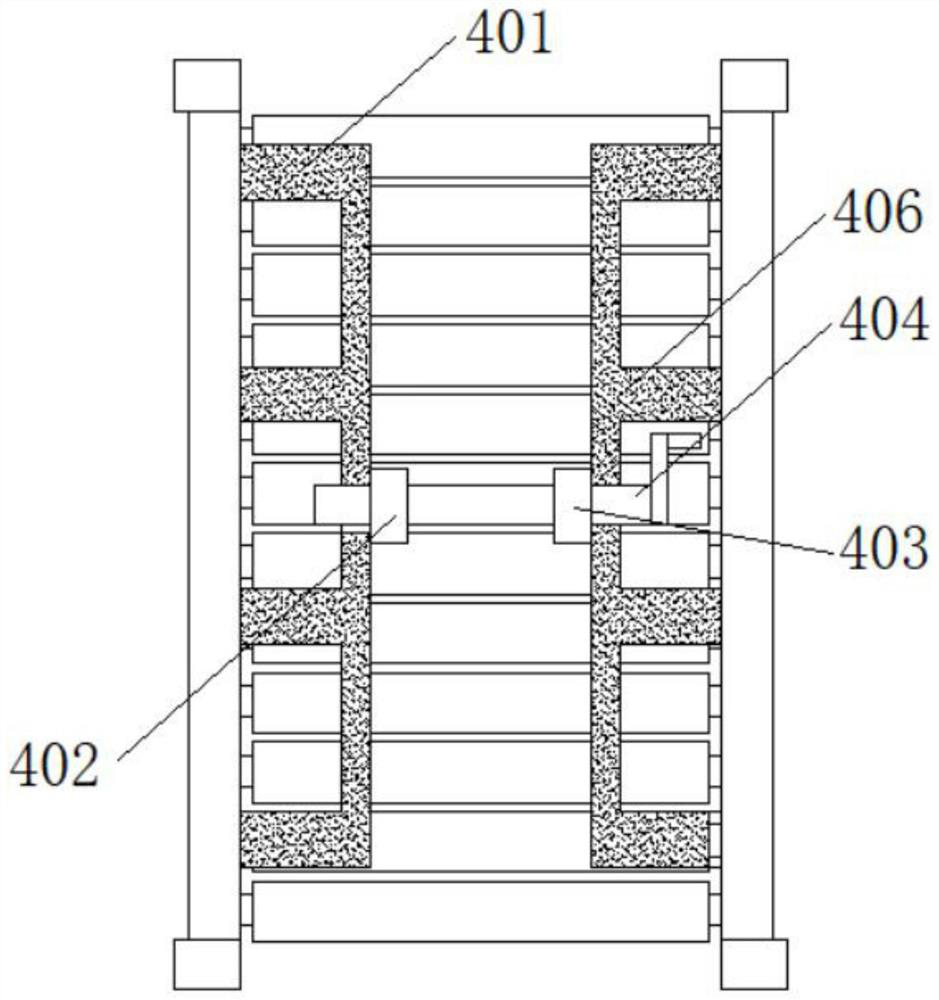

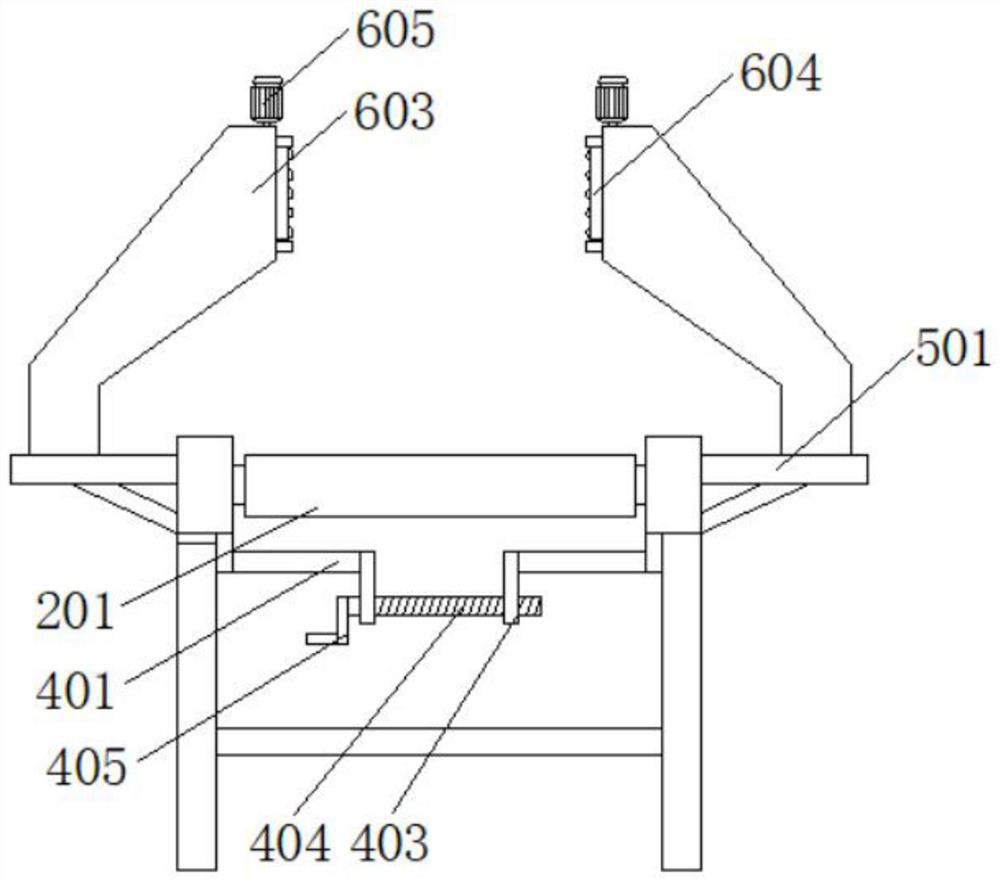

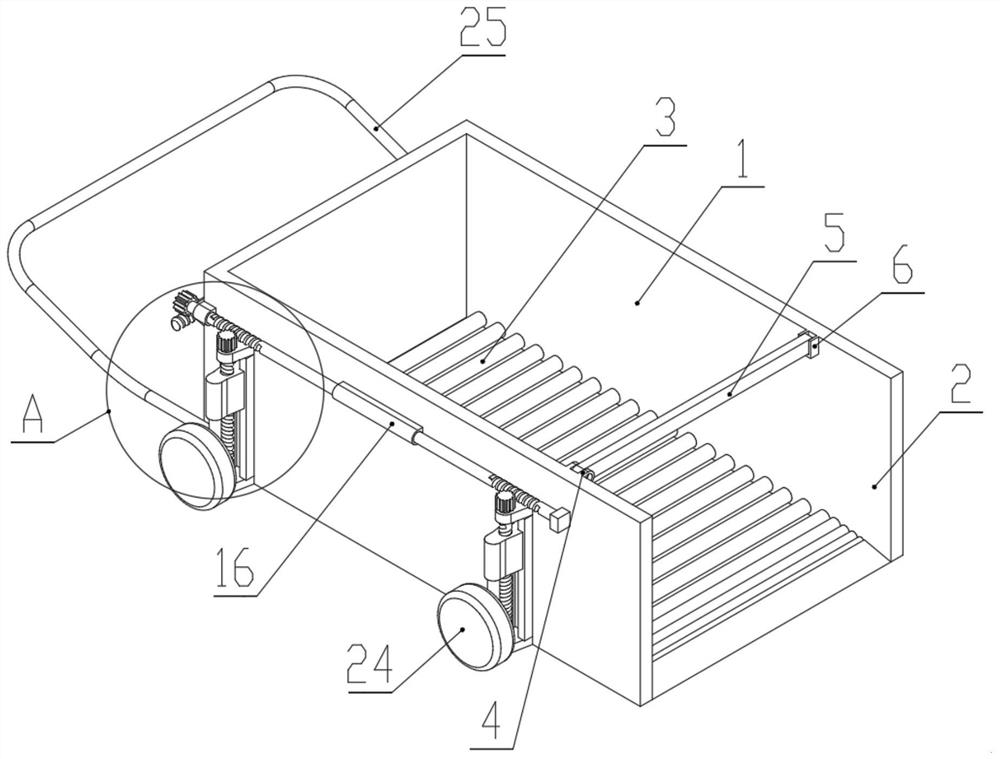

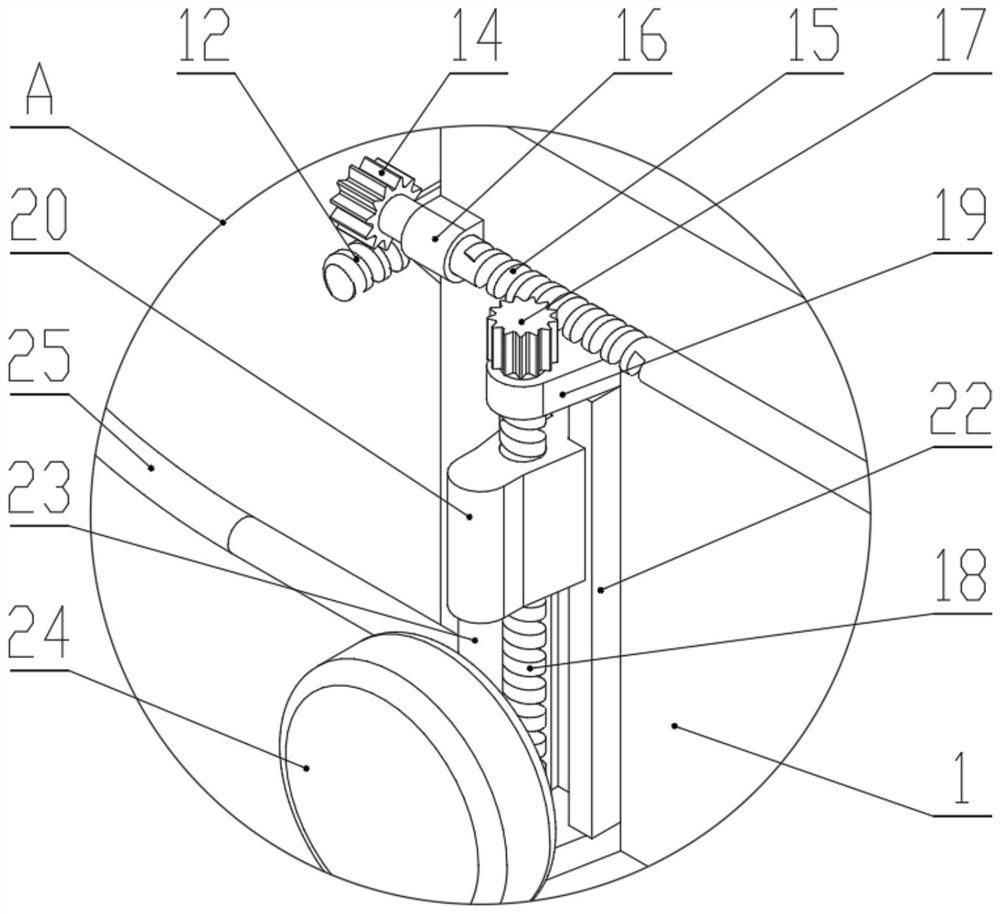

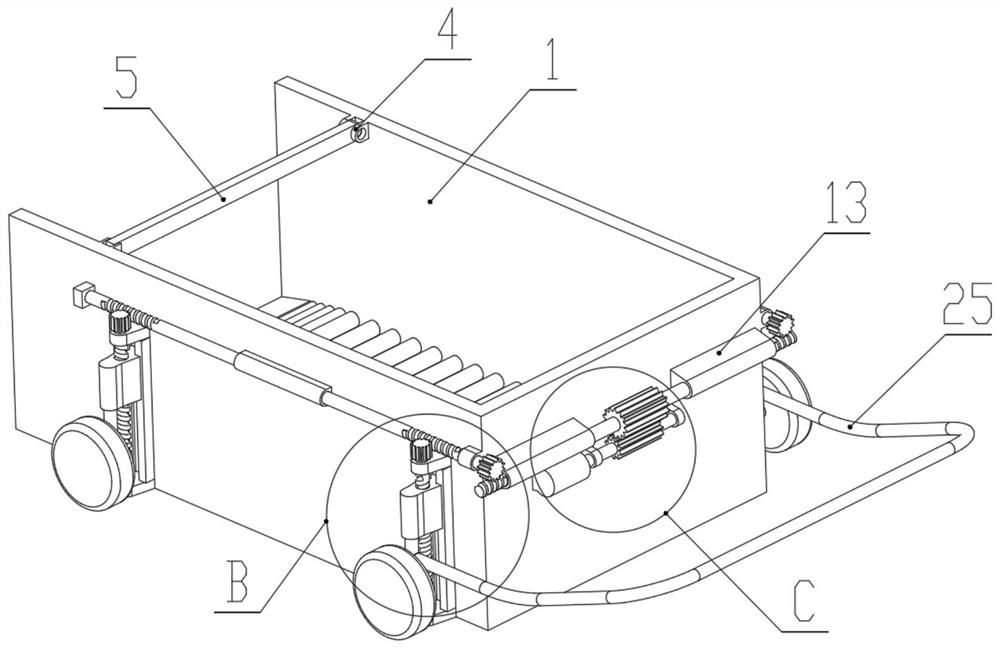

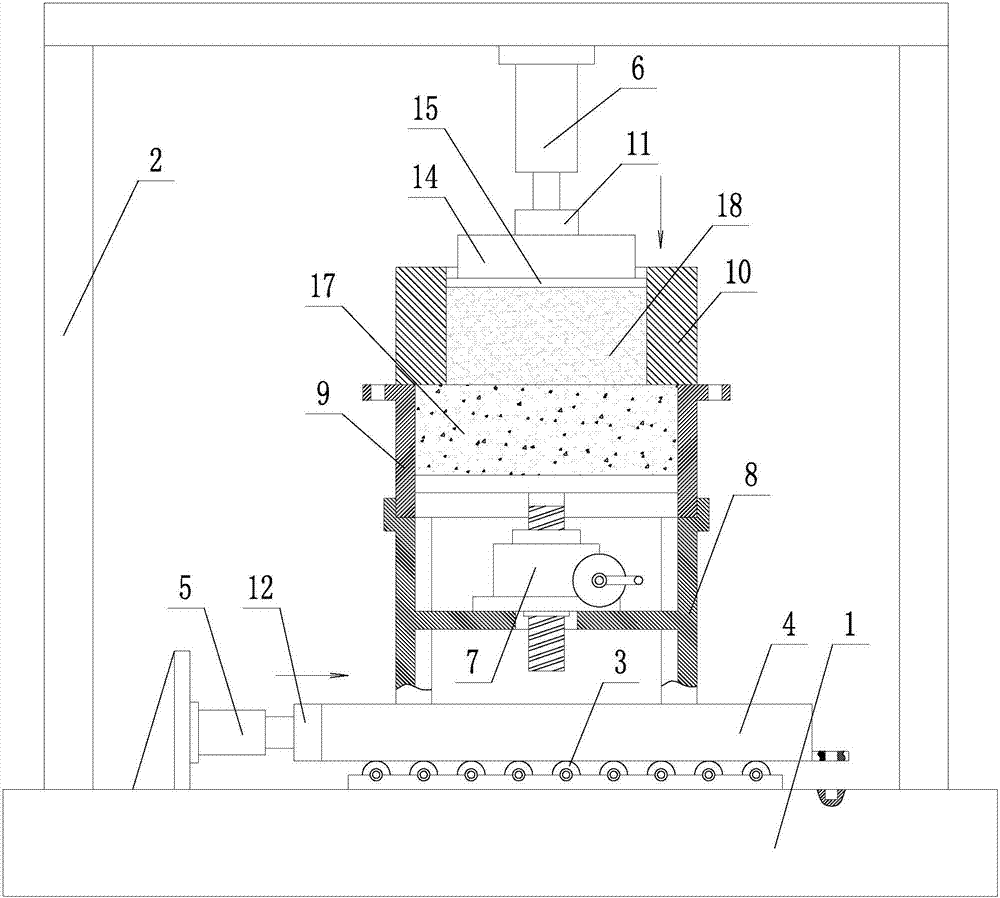

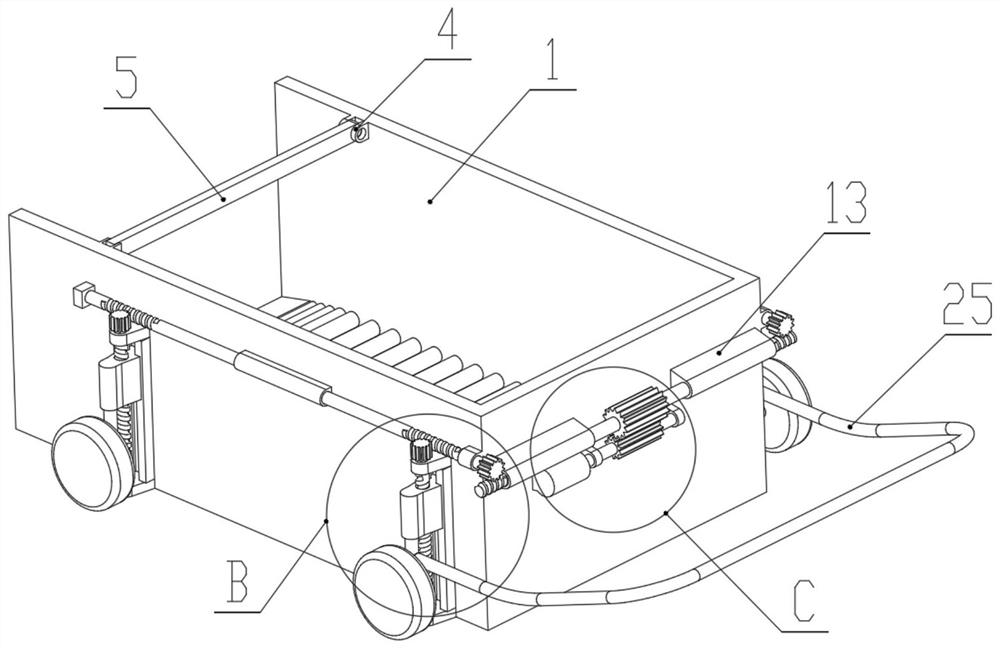

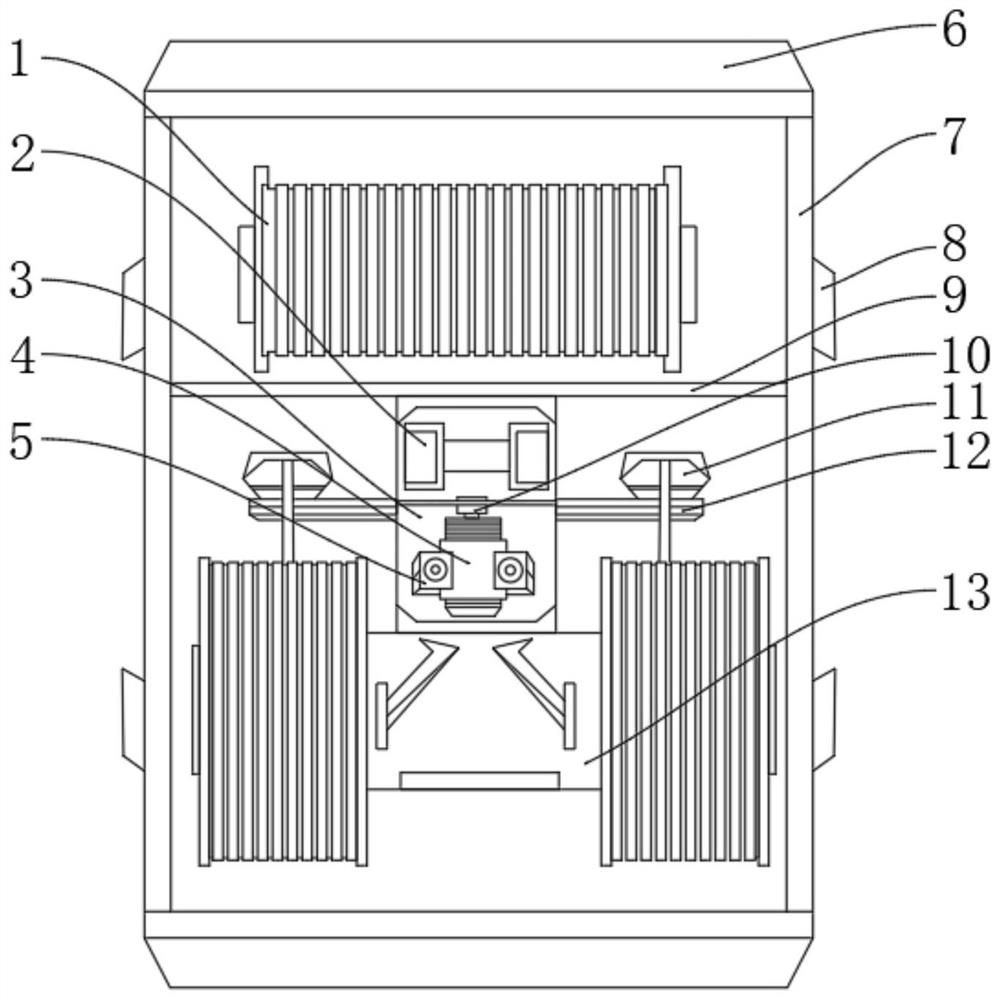

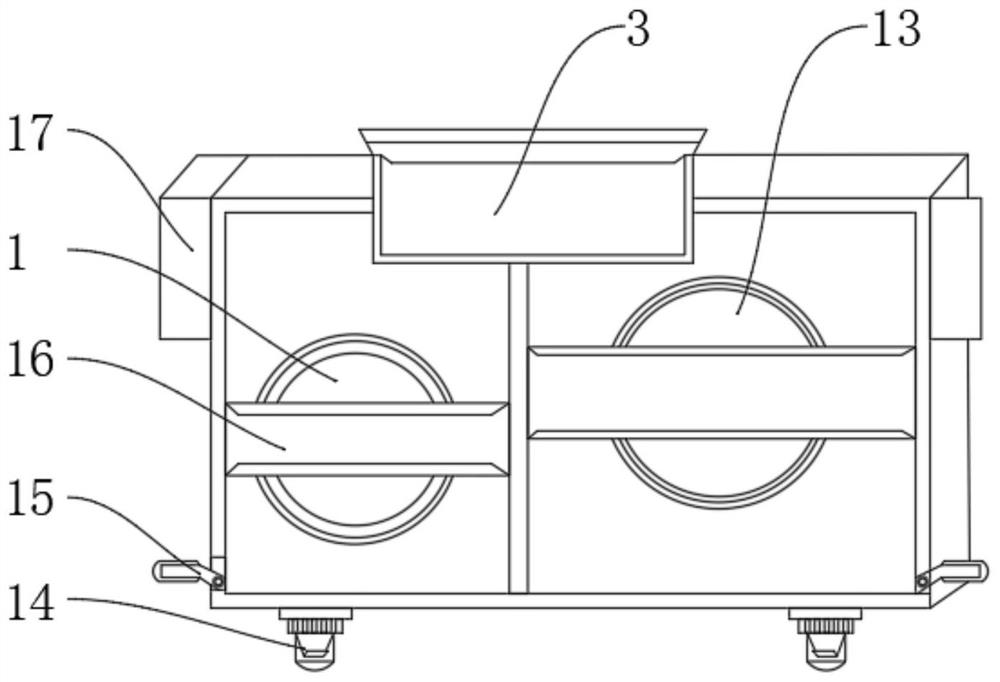

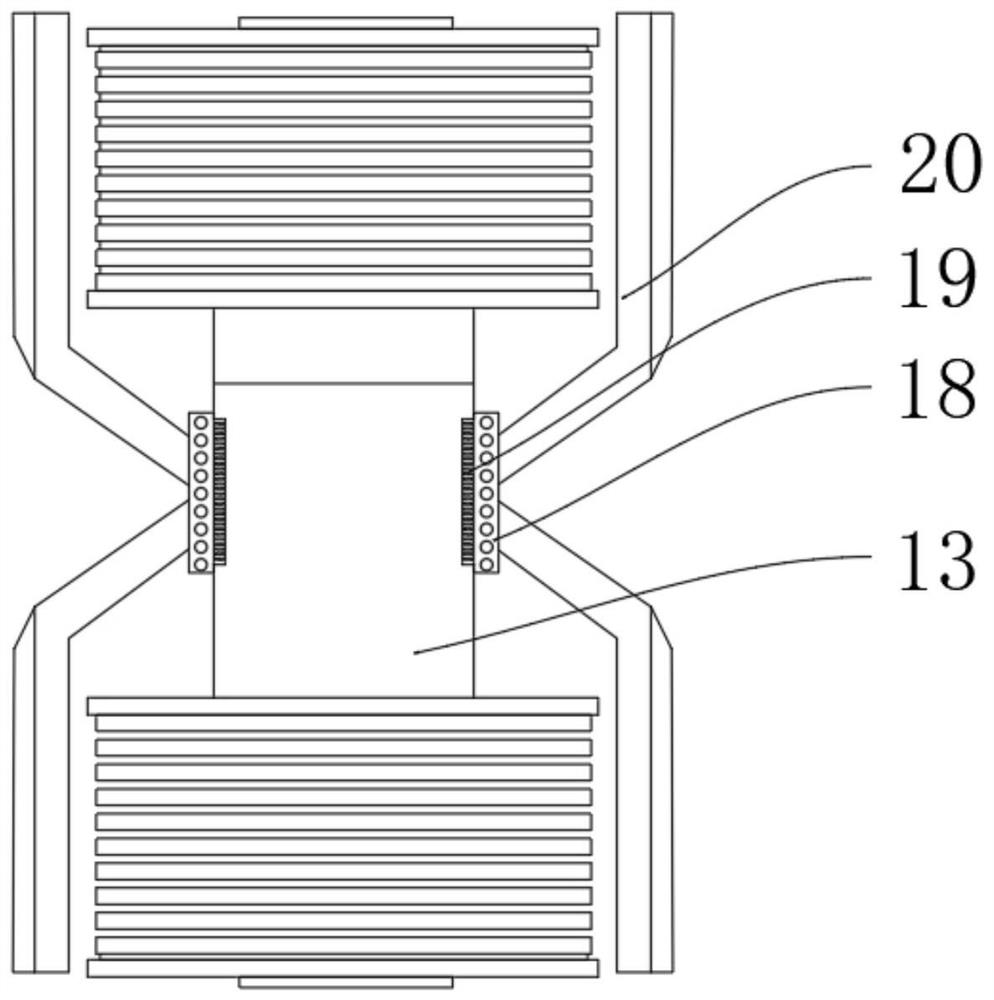

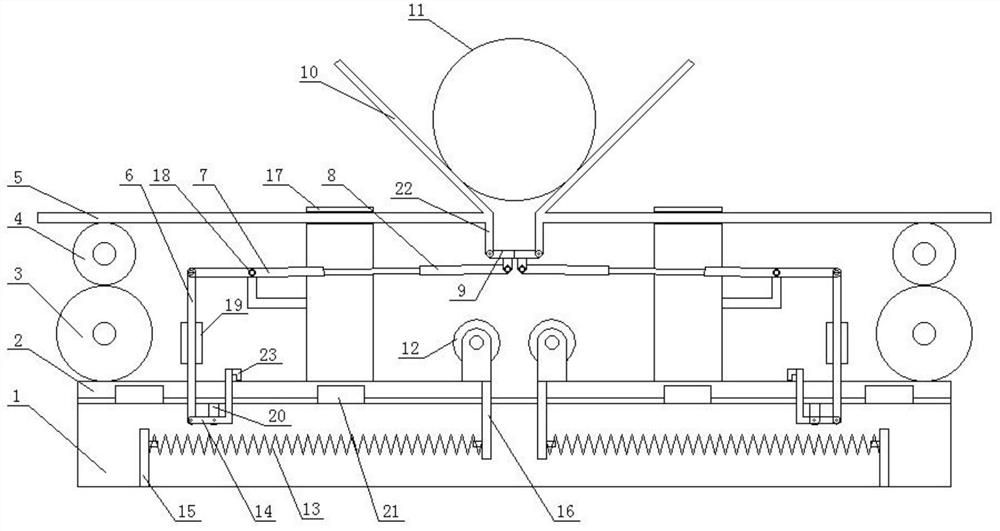

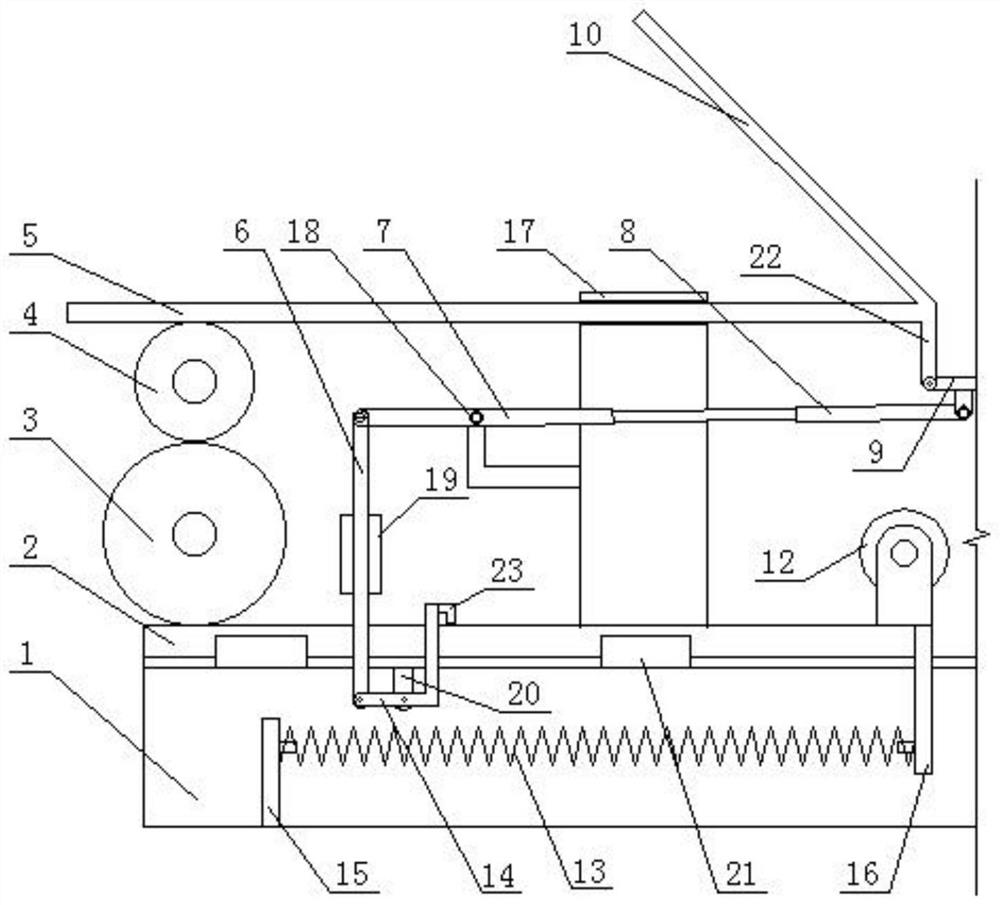

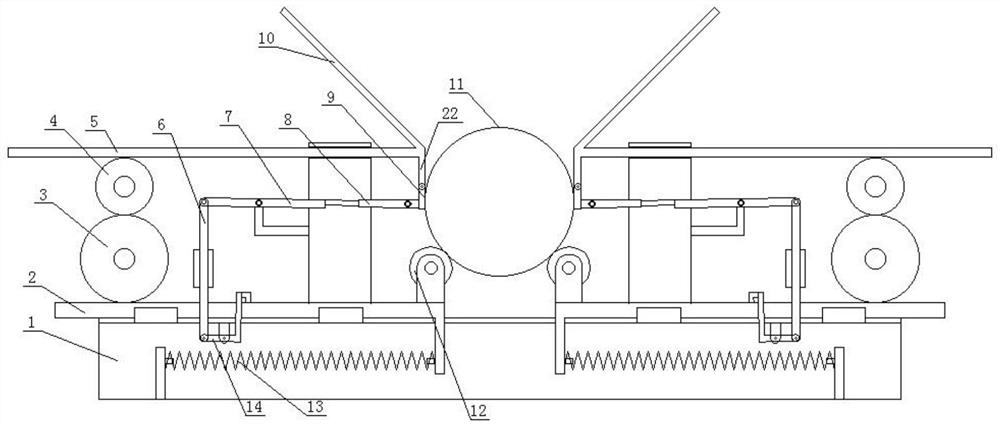

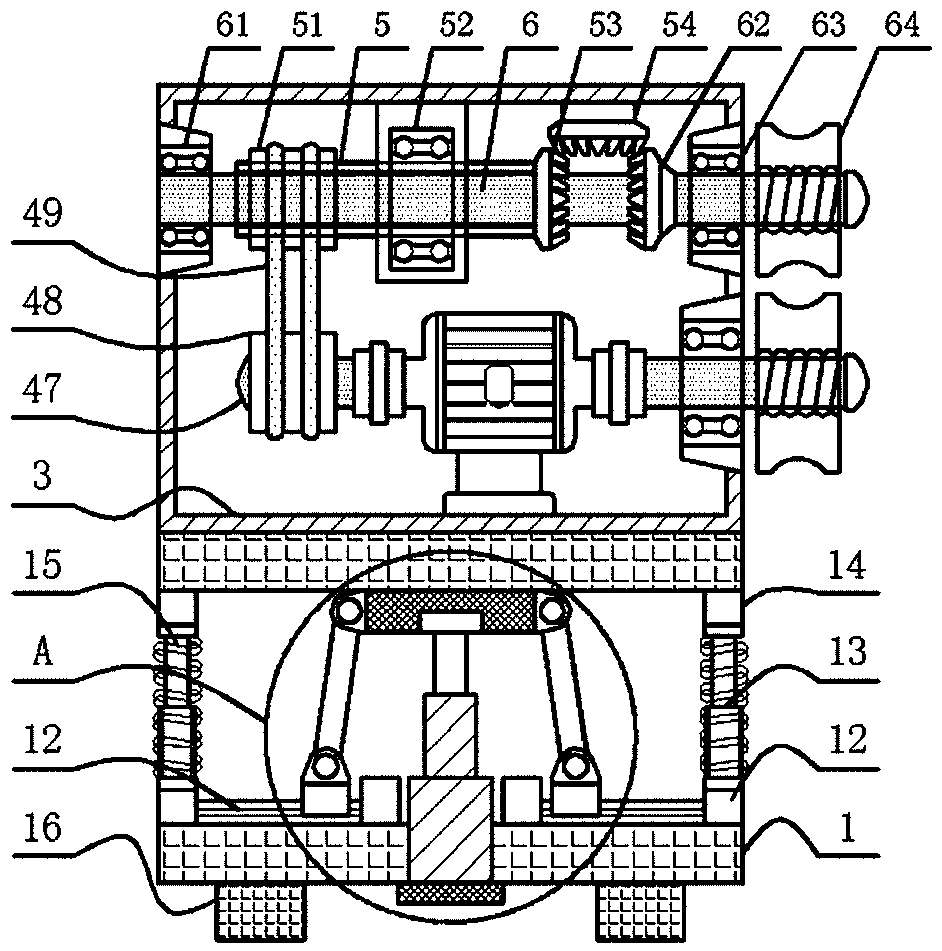

Damping ball mill convenient to move

PendingCN110882766AImprove crushing efficiencyPlay a buffer roleNon-rotating vibration suppressionGrain treatmentsGear wheelDrive shaft

The invention relates to the field of grinding equipment. More particularly, the present invention relates to the damping ball mill which is convenient to move. The ball mill comprises a tabletop, a mounting frame, a stirring shaft and a barrel body; a mounting frame is arranged above the tabletop; damping springs are distributed on the lower surface of the mounting frame; the lower ends of the damping springs are fixedly connected with the upper surface of the tabletop; the stirring shaft is mounted in the mounting frame; the middle part of the stirring shaft is sleeved with the barrel body;the barrel body is rotationally connected with the stirring shaft; stirring blades are distributed on the stirring shaft; a gear ring is sleeved on the barrel body; the outer side wall of the mountingframe is fixedly connected with a motor; the shaft extension end of the motor is fixedly connected with a driving shaft; the driving shaft is sleeved with a gear; and the gear is meshed with the gearring. According to the invention, the motor is used for driving the barrel body to rotate, and the stirring blades are used for stirring to-be-crushed materials, so the crushing efficiency is improved; and the damping springs can achieve a certain damping effect. The damping springs can achieve the damping effect, so the vibration generated during operation of the ball mill is reduced, and the ball mill can be conveniently pushed to move by arranging the rolling shaft capable of ascending and descending.

Owner:ZHUZHOU LIANXIN METAL CO LTD

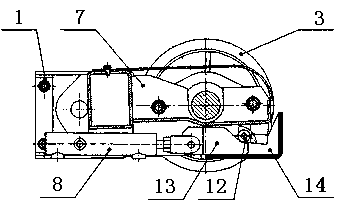

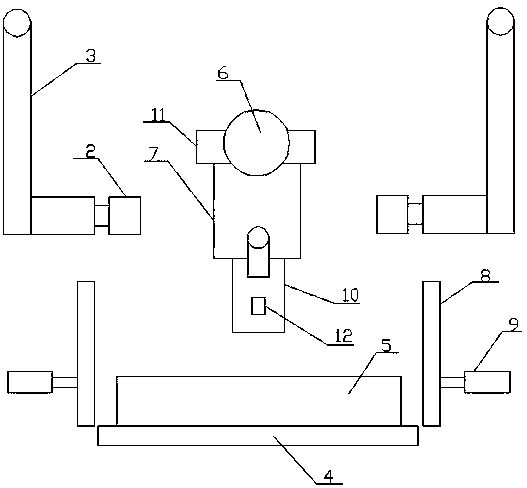

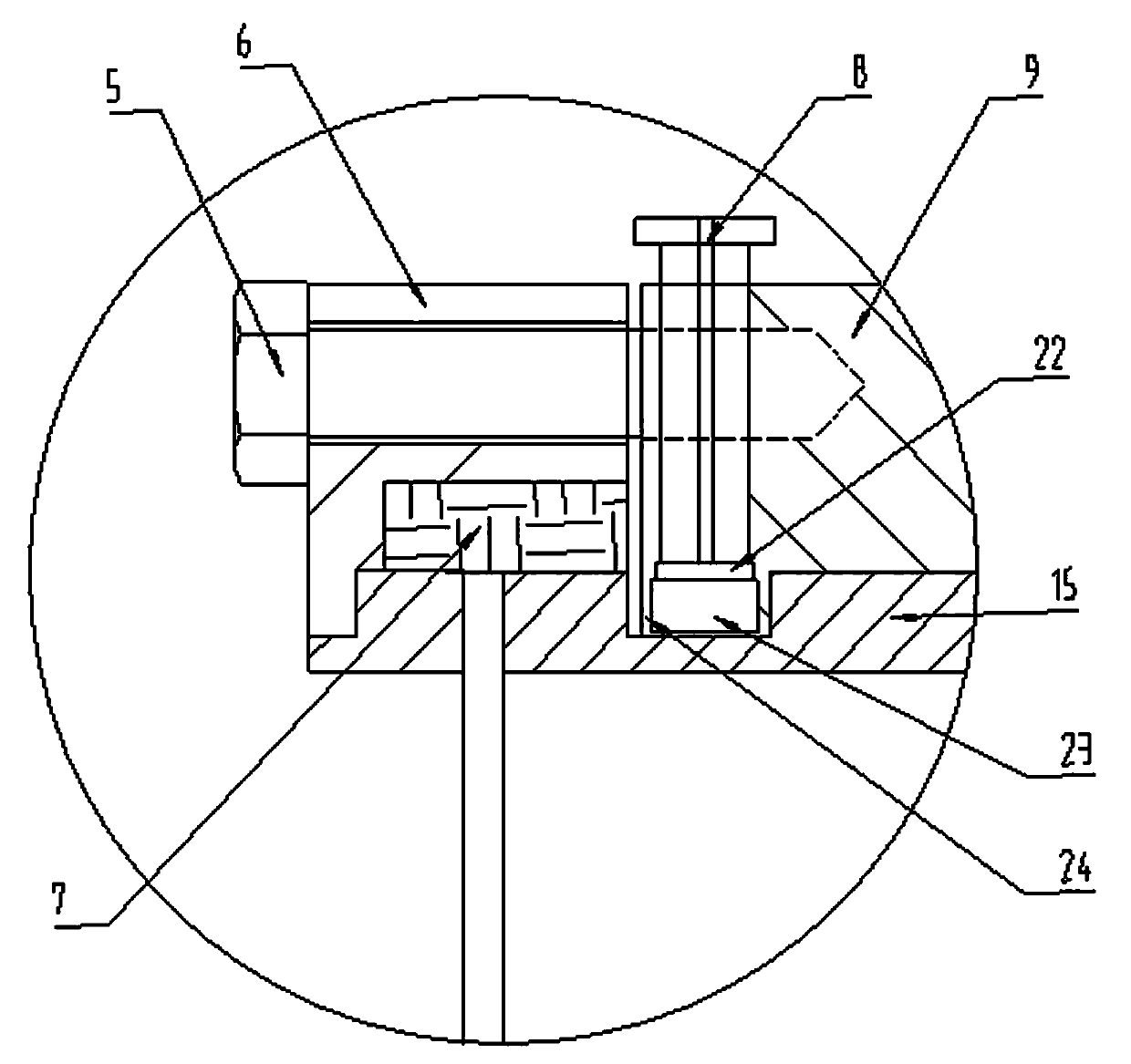

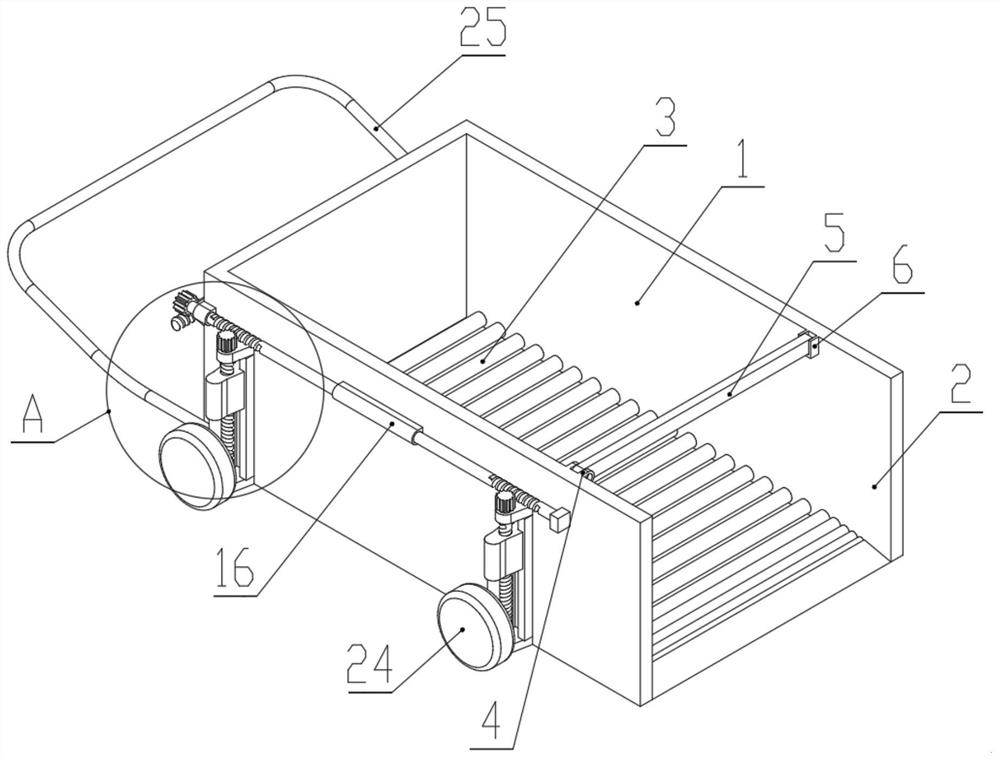

Lifting device for transmission roller of conveying platform

ActiveCN103640710AGuaranteed tensionNovel structureFreight handling installationsLoading/unloadingClassical mechanicsSprocket

The invention discloses a lifting device for a transmission roller of a conveying platform. The lifting device is characterized by being provided with a platform frame, a supporting arm, bearing seats, a rolling pulley, a wedge block and a loading pile, wherein fixed brackets are arranged at two ends of a lifting swing arm, rotating shafts are arranged on the fixed brackets, the two ends of the lifting swing arm are respectively fixed on fixed plates, the supporting arm is arranged at the front end of the center, the rear end is articulated with the rotating shafts, the lower end is provided with a telescopic oil cylinder, a driving roller is arranged on the front part, the rear ends of the fixed plates are articulated with the rotating shafts, a positioning groove is formed in the upper end surface of the supporting arm, the rolling pulley is arranged at the lower end of the supporting arm, the wedge block is arranged below the supporting arm, the middle part of a driving rolling shaft is seated in the supporting arm, two ends of the driving rolling shaft are respectively connected with the bearing seats, the driving roller and a driven sprocket are fixed on the driving rolling shaft, the wedge block is arranged in the loading pile, the upper end surface of the wedge block contacts with the rolling pulley, the lower end of the wedge block is in sliding connection with the loading pile, the telescopic oil cylinder is fixedly connected with the wedge block, and the loading pile is fixedly connected with the platform frame. The lifting device has the advantages of novel structure, safety and reliability, and the like.

Owner:WEIHAI GUANGTAI AIRPORT EQUIP CO LTD

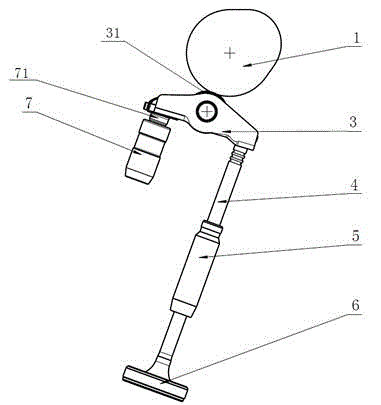

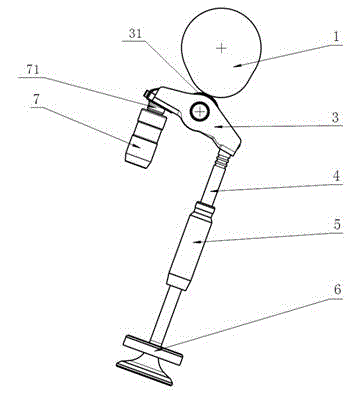

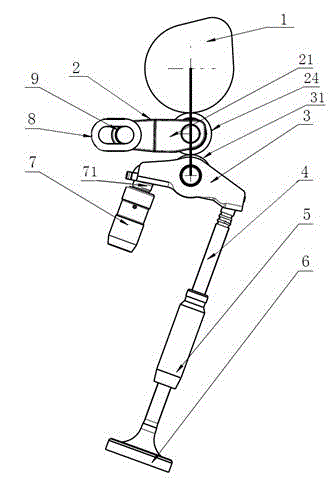

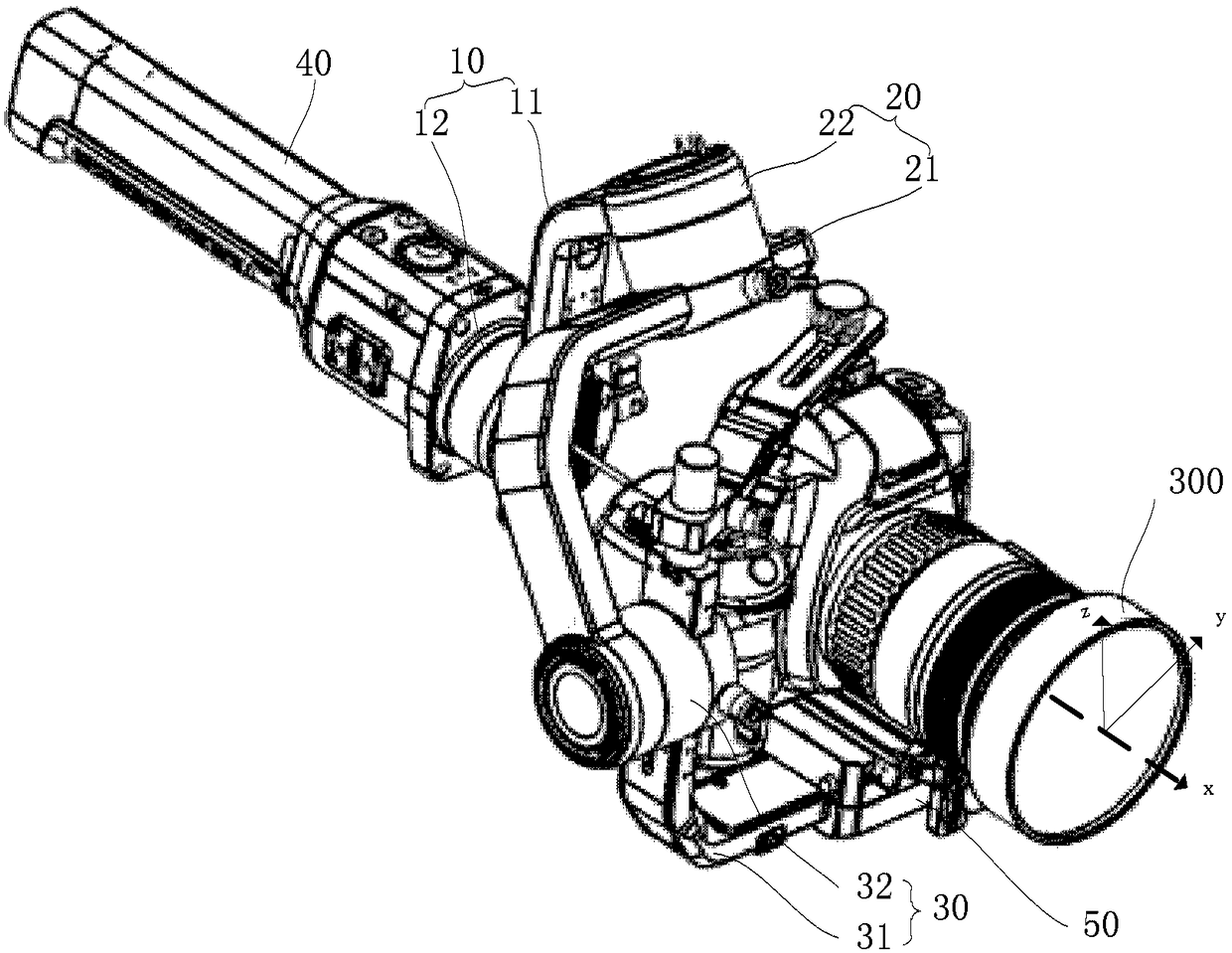

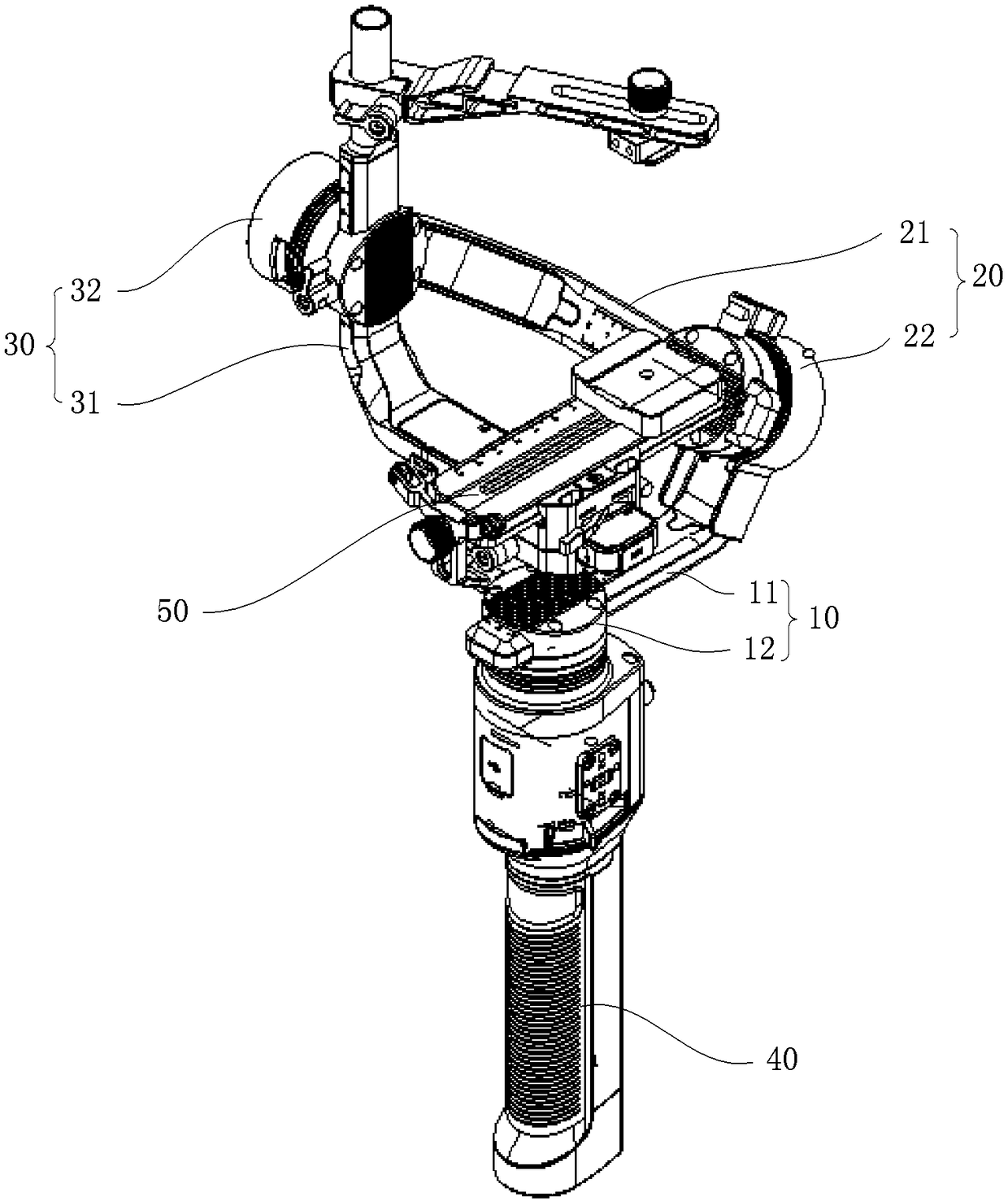

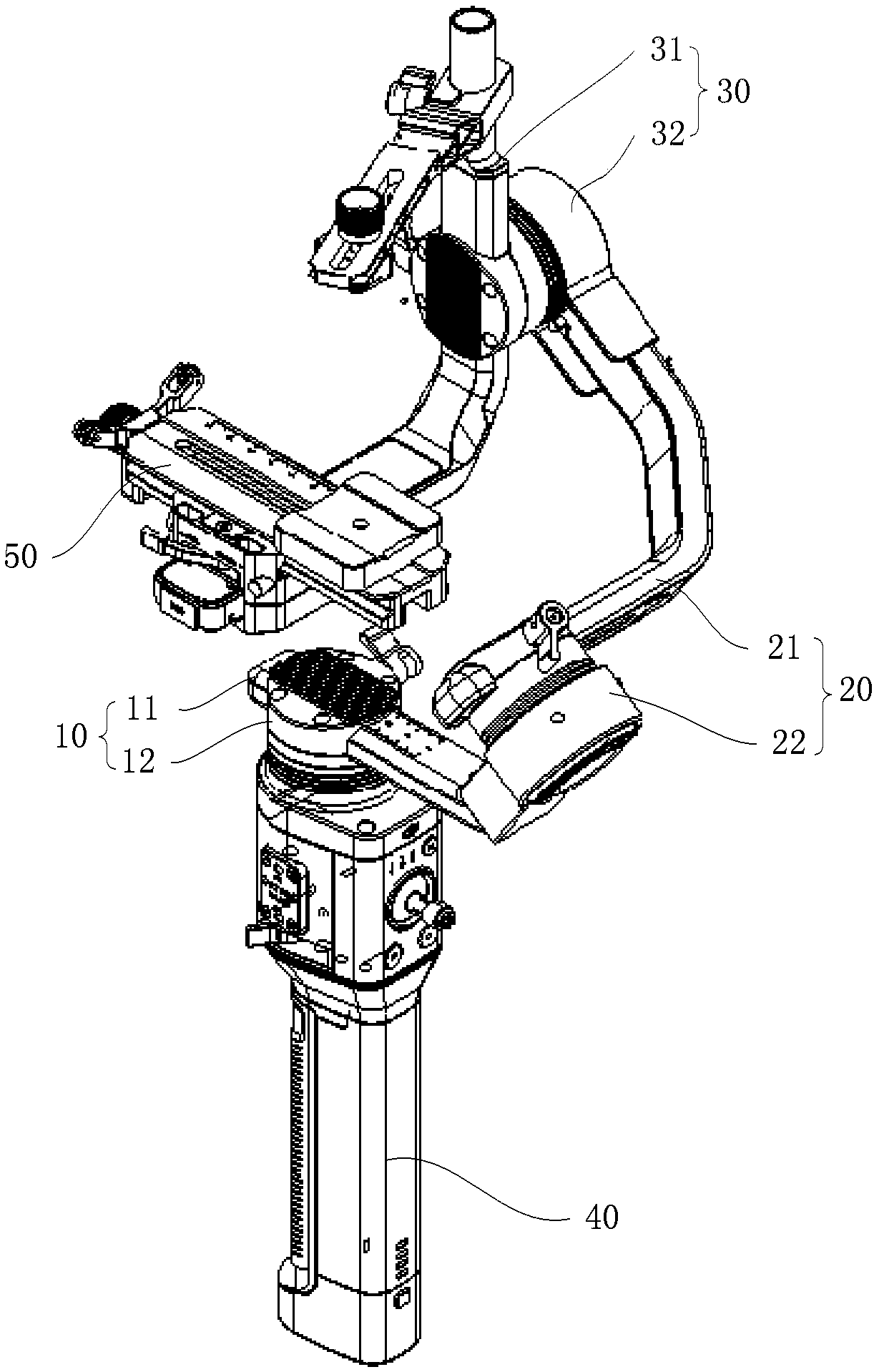

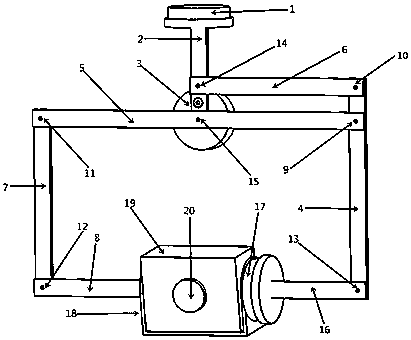

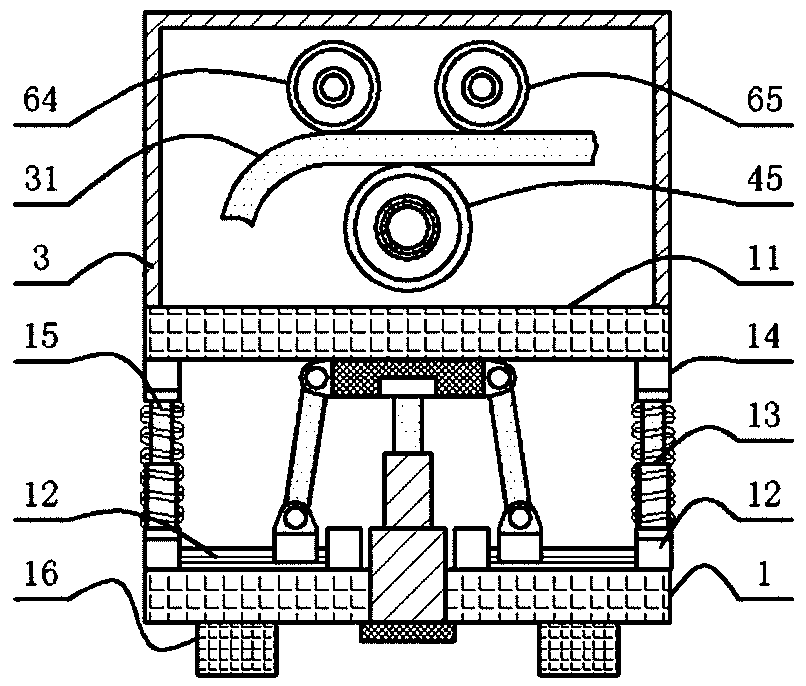

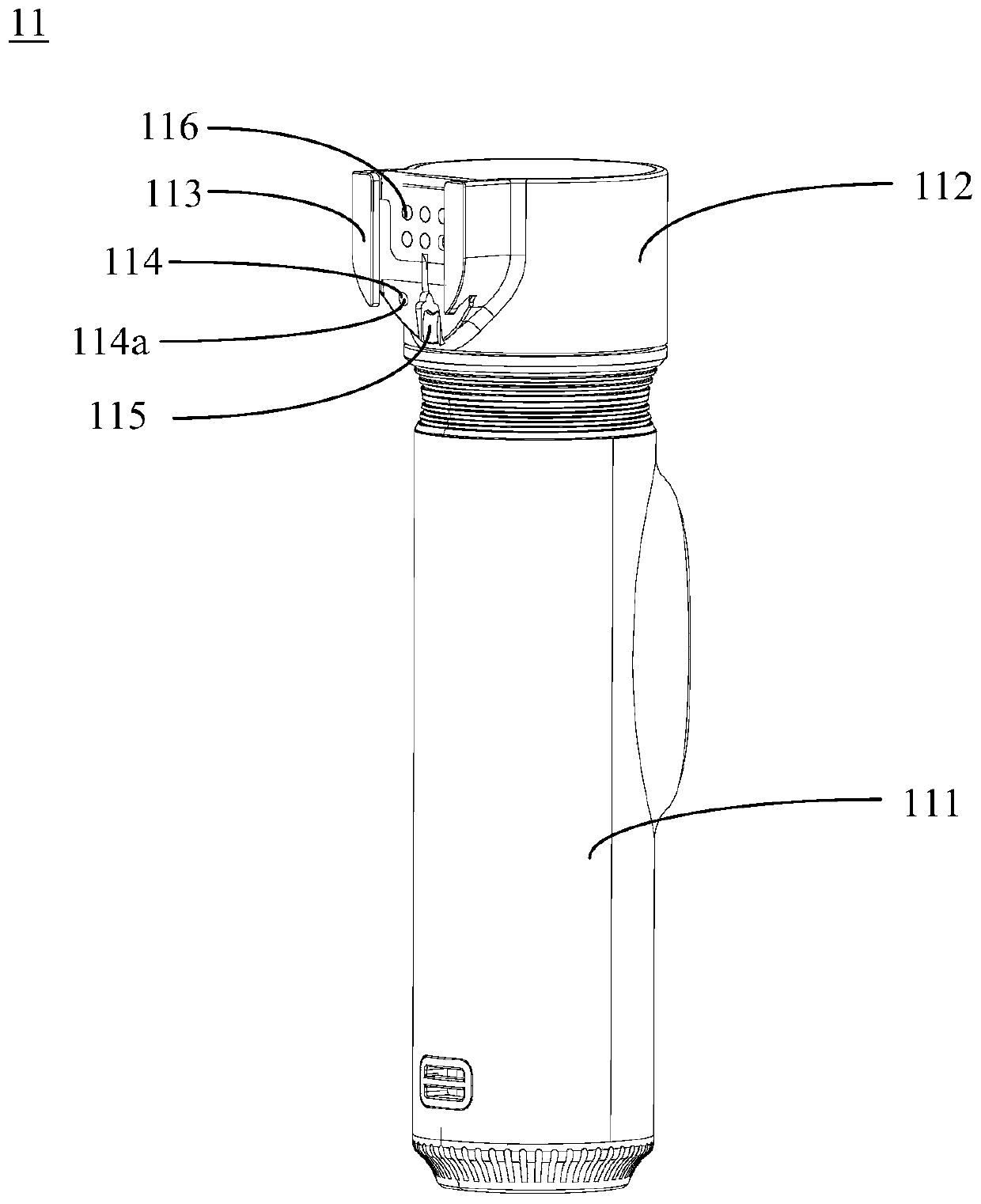

Pan/tilt and control method thereof, and drone

ActiveCN108323191ARealize large angle rotationAircraft componentsProgramme controlElectric machineryRolleron

The invention provides a pan / tilt and a control method thereof, the drone, wherein the pan / tilt comprises a first shaft assembly, a second shaft assembly and a third shaft assembly; the first shaft assembly comprises a first shaft arm and a first motor mounted at one end of the first shaft arm; the second shaft assembly comprises a second shaft arm and a second motor mounted at one end of the second shaft arm; the third shaft assembly comprises a third shaft arm and a third motor mounted at one end of the third shaft arm;one end far from the first motor of the first shaft arm is fixedly connected with te second motor; one end far from the second motor of the second shaft arm is fixedly connected with the third motor, and the third shaft arm is used for carrying a load; the first motor canserve as a horizontal roller motor, the second motor an serve as one of a yaw motor and a pitch axis motor, and the third motor can serve as the other of the yaw axis motor and the pitch axis motor; and the horizontal roller motor rotates to drive the load to rotate arount the x axis, to drive the yaw axis motor and the pitch axis motor to rotate around the rotary shaft of the horizontal roller shaft at the same time, so as to avoide mad rotation of the pan / tilt.

Owner:SZ DJI TECH CO LTD

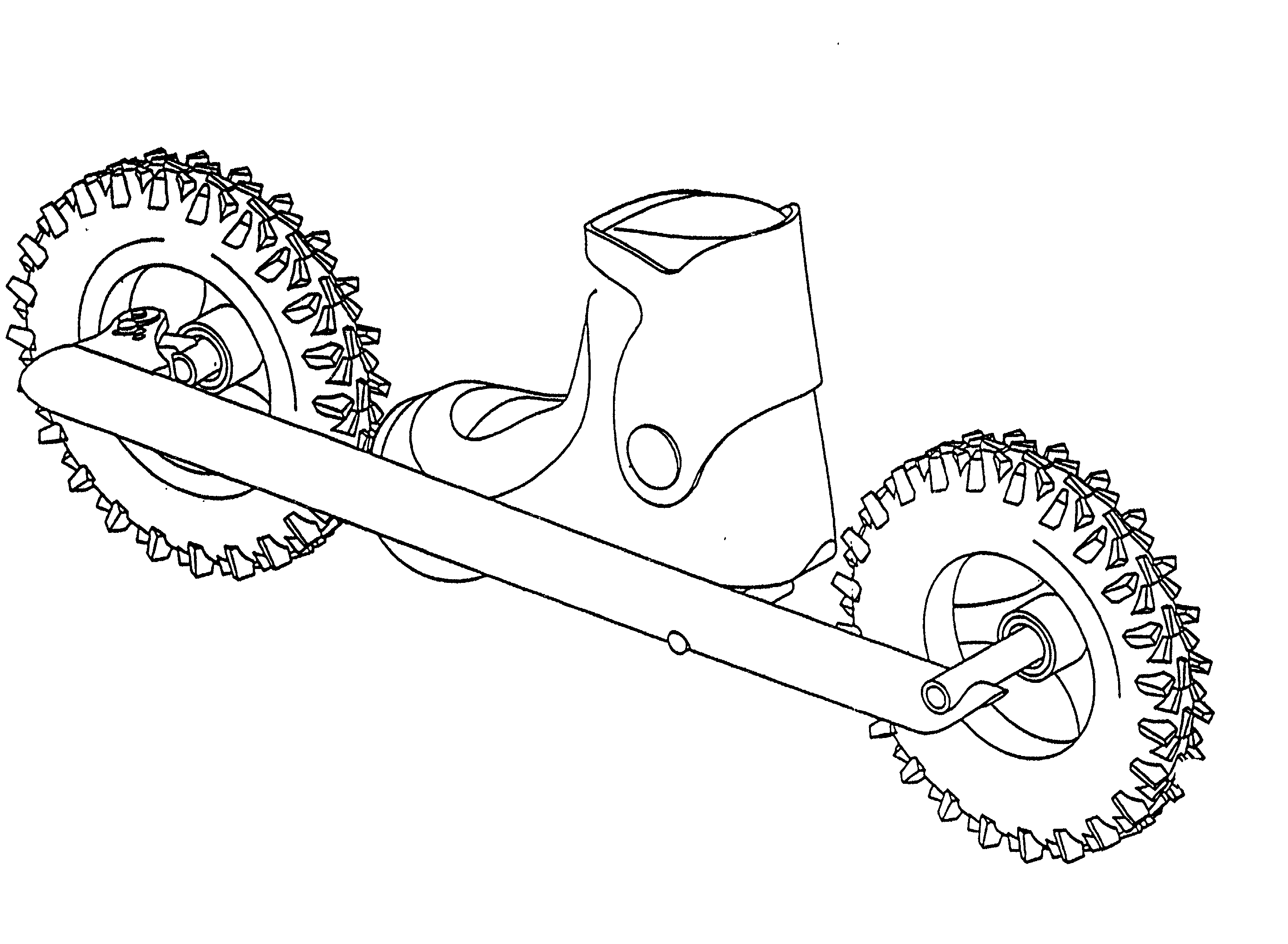

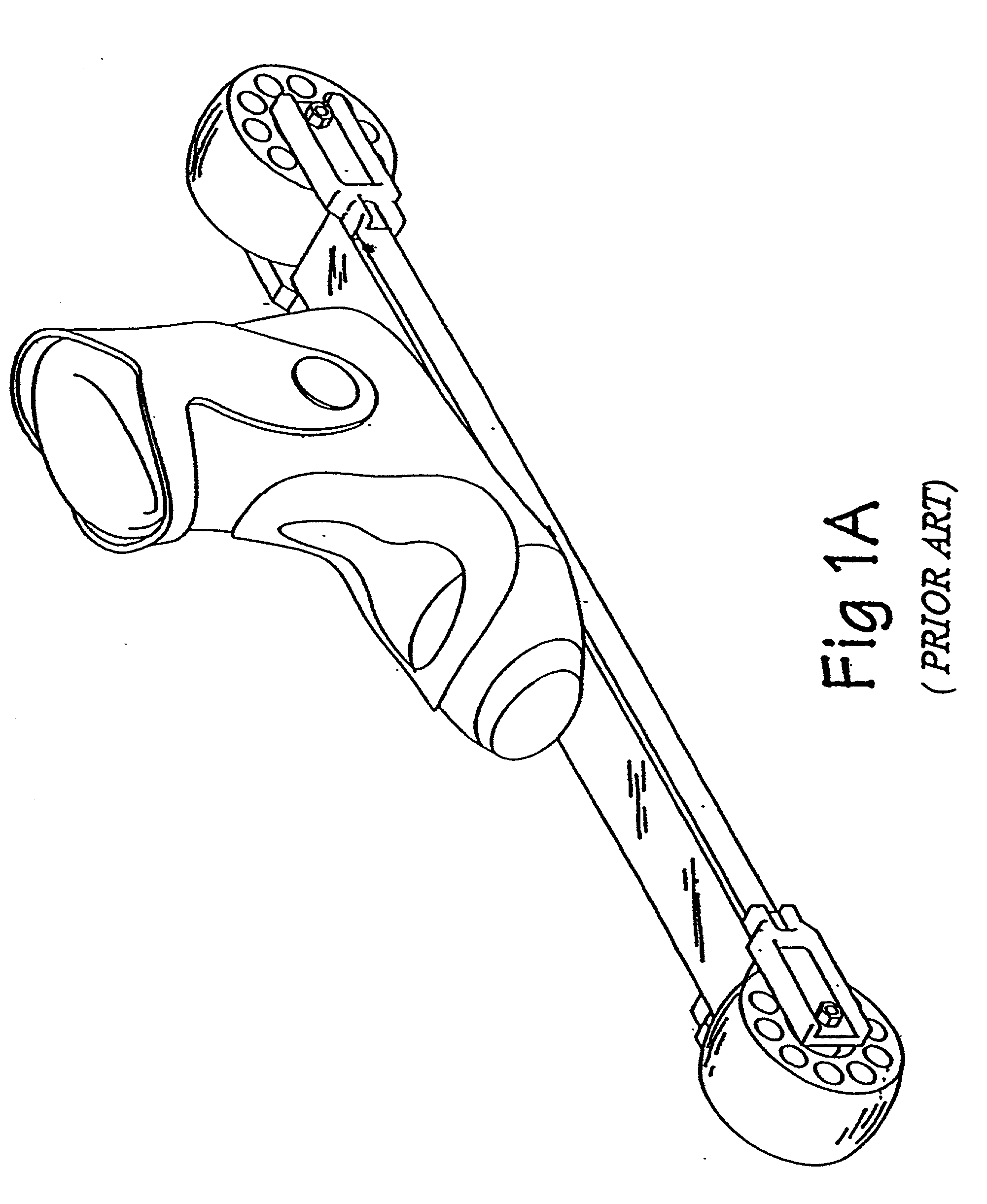

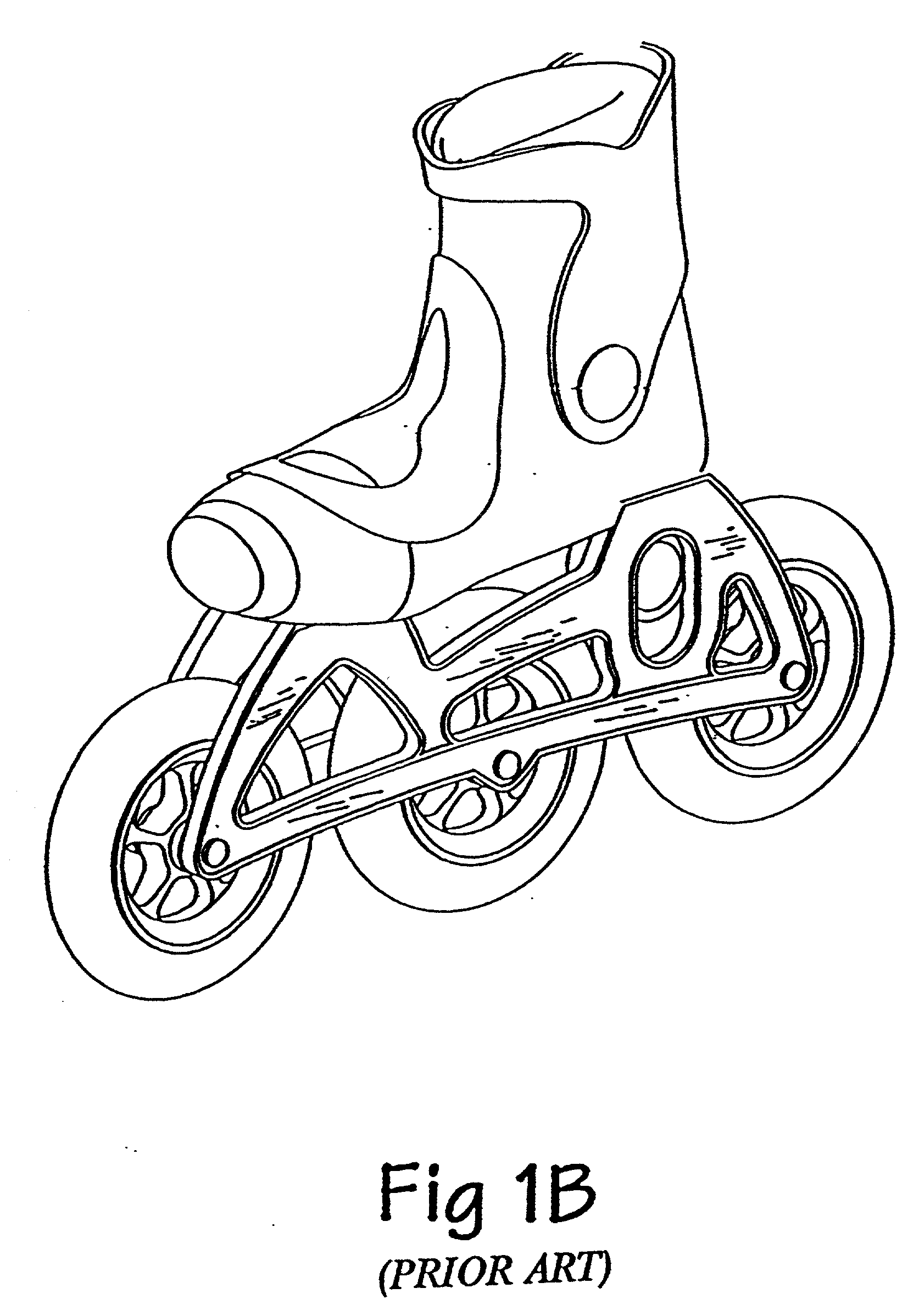

Steering and braking in-line skate or roller ski

A steerable wheeled device such as an in-line skate or roller ski has a hollow or dish-shaped wheel, a wheel bearing, and a wheel support connecting the wheel to a steering structure that extending substantially within the outer radius of the wheel, and steers as the user's weight is displaced. The device preferably has a side-mounted chassis, and oversize wheel positioned in front and in back of the user's foot. The chassis may contain a damping and centering force mechanism to moderate behavior of the steering or suspension. Brakes such as drum or disk brakes are connected to one or more wheels and preferably actuated, e.g., with a boot-actuated linkage, such that braking occurs upon the user adopting a specific posture. In a preferred construction, the stance shifts weight back and / or down so that deceleration does not occur until the user has assumed a stable stance.

Owner:PAGE JAMES S +2

Rotary cleaning device for production of roller shaft seat and one-way wheel of fax machine

ActiveCN107755313AChange direction of rotationAchieve cleaning effectCleaning using toolsDrive wheelGear wheel

The invention discloses a rotary cleaning device for production of a roller shaft seat and a one-way wheel of a fax machine. The rotary cleaning device comprises supporting legs, wherein a support table is fixedly connected to the top of the supporting legs; a first support rod is fixedly connected to the lower surface of the support table; a first motor is fixedly connected to the middle of the first support rod; an output shaft of the first motor is fixedly connected with a first rotating shaft through a coupling; and a driving wheel is fixedly connected to the surface of the first rotatingshaft. According to the rotary cleaning device for production of the roller shaft seat and the one-way wheel of the fax machine, the effect of cleaning the surfaces of the roller shaft seat and the one-way wheel is achieved; a second rotating shaft and a third rotating shaft rotate to drive cleaning brushes to scrub and clean the surfaces of the roller shaft seat and the one-way wheel; meanwhile,as the outer surface of a driven gear meshes with that of a driving gear, the rotating direction of the third rotating shaft can be changed, swirling is prevented, and accordingly, the problem that acommon roller shaft seat and one-way wheel cleaning device has high probability of causing retention of oil dirt and impurities is effectively solved.

Owner:佛山市常捷粉末冶金科技有限公司

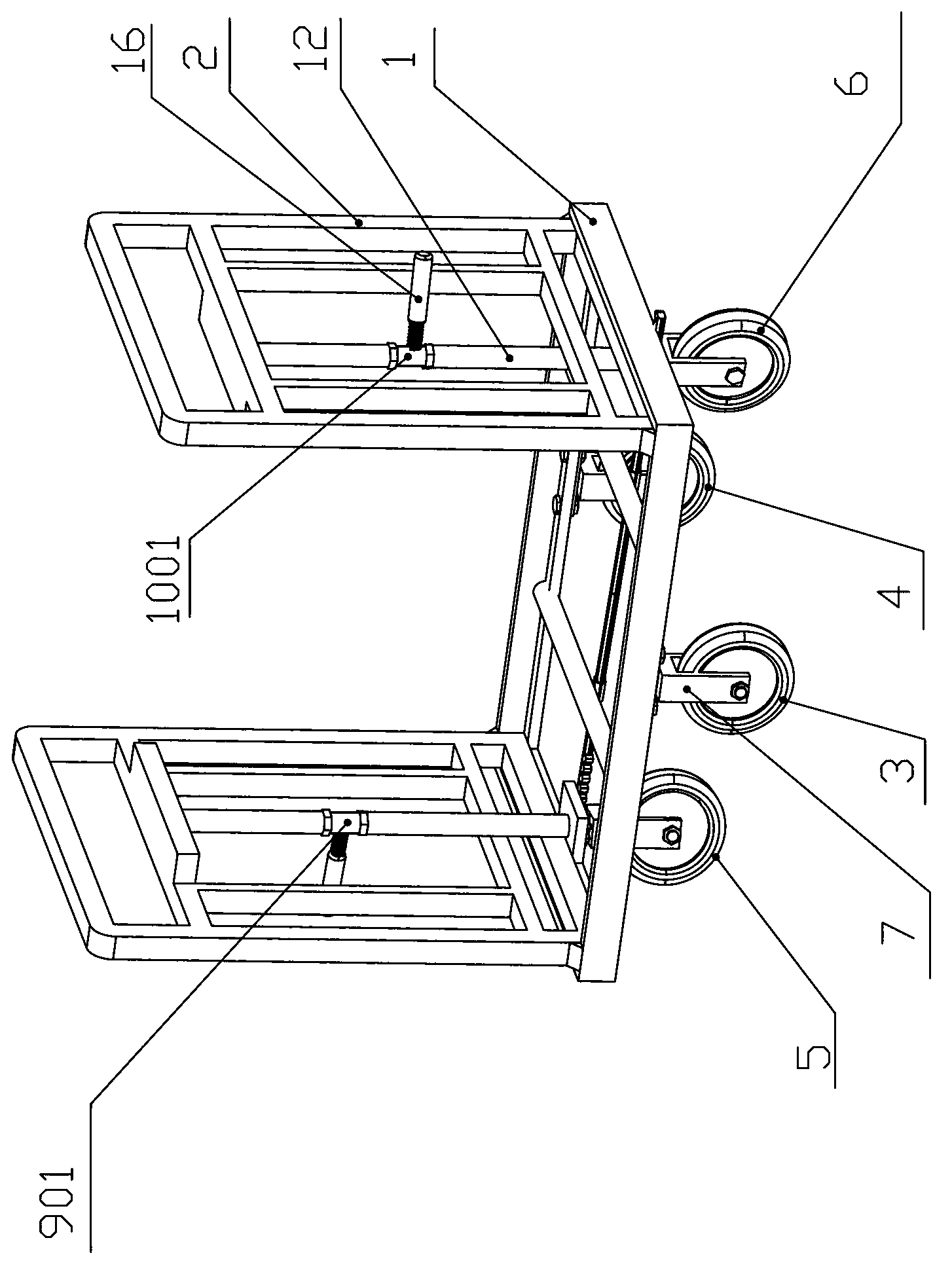

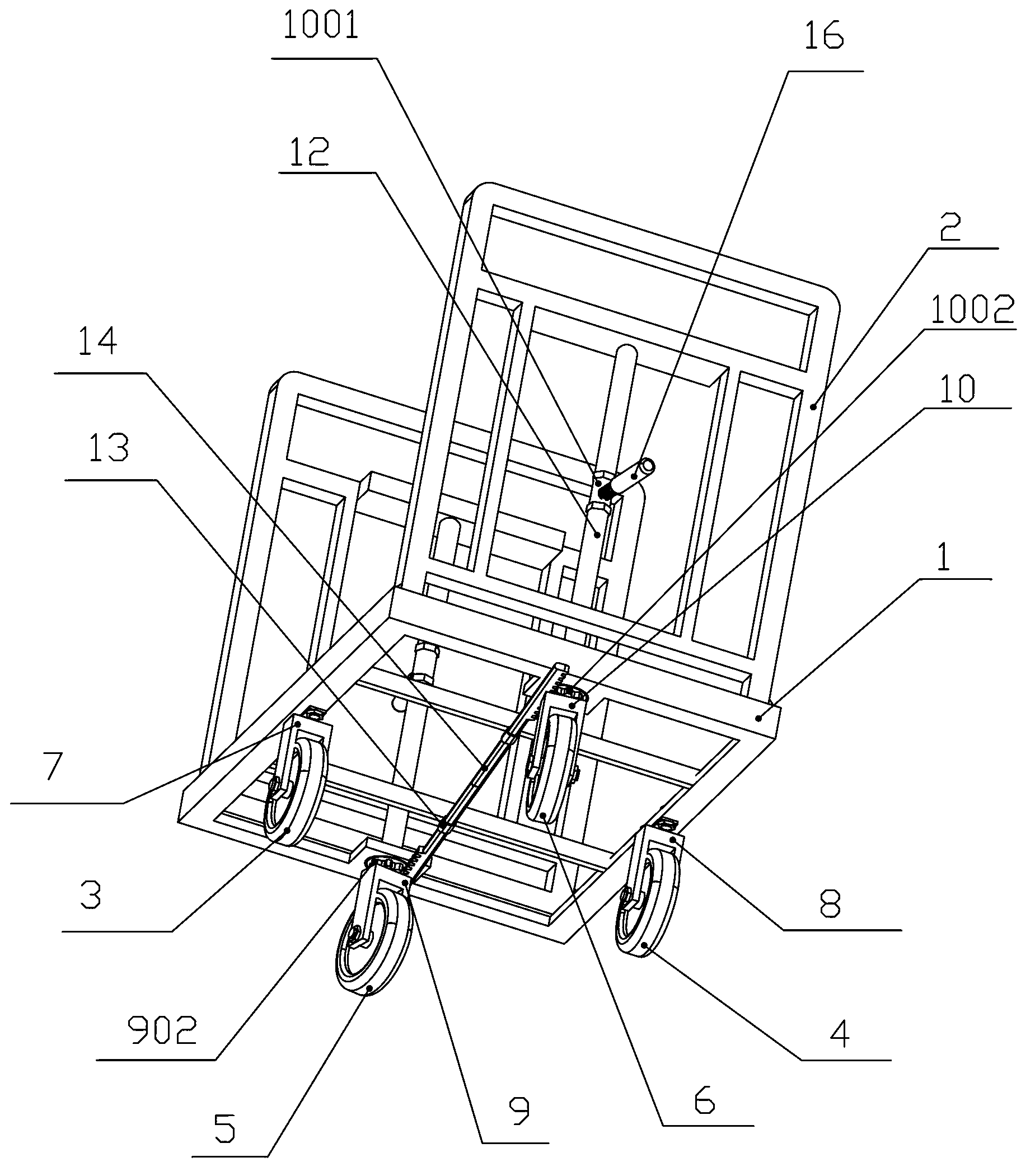

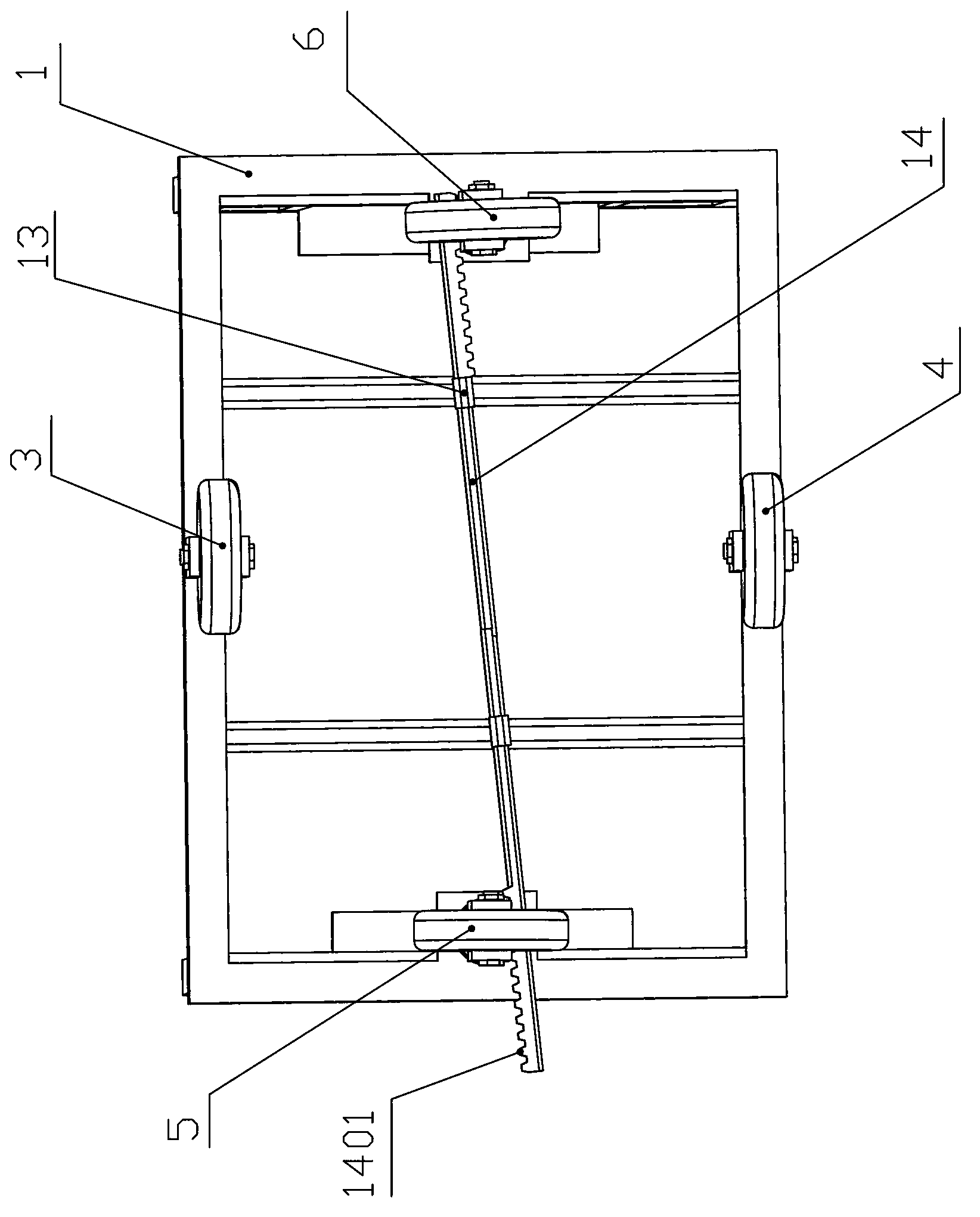

Four-wheeled hand truck capable of achieving pivot steering

The invention relates to a four-wheeled hand truck, in particular to a four-wheeled hand truck capable of achieving pivot steering. The four-wheeled hand truck comprises a frame, handles connected with the frame, a left roller, a right roller, a front roller and a rear roller, the left roller and the right roller are fixed and arranged at middle positions of two sides of the frame, the front roller and the rear roller are arranged at middle positions of the front end and the rear end of the frame and capable of steering, and a rotating link gear capable of rotating synchronously in opposite directions is arranged between a front roller support and a rear roller support. When the four-wheeled hand truck is pushed forward linearly, rolling shafts of the front roller and the rear roller and rolling shafts of the left roller and the right roller are adjusted to be parallel, and the four-wheeled hand truck can easily keep moving forward linearly; and when the rolling shaft of the front roller is adjusted to be perpendicular to the rolling shaft of the rear roller, the rolling shafts of the front roller and the rear roller are perpendicular to the rolling shafts of the left roller and the right roller, and the four-wheeled hand truck can achieve pivot steering.

Owner:王金虎

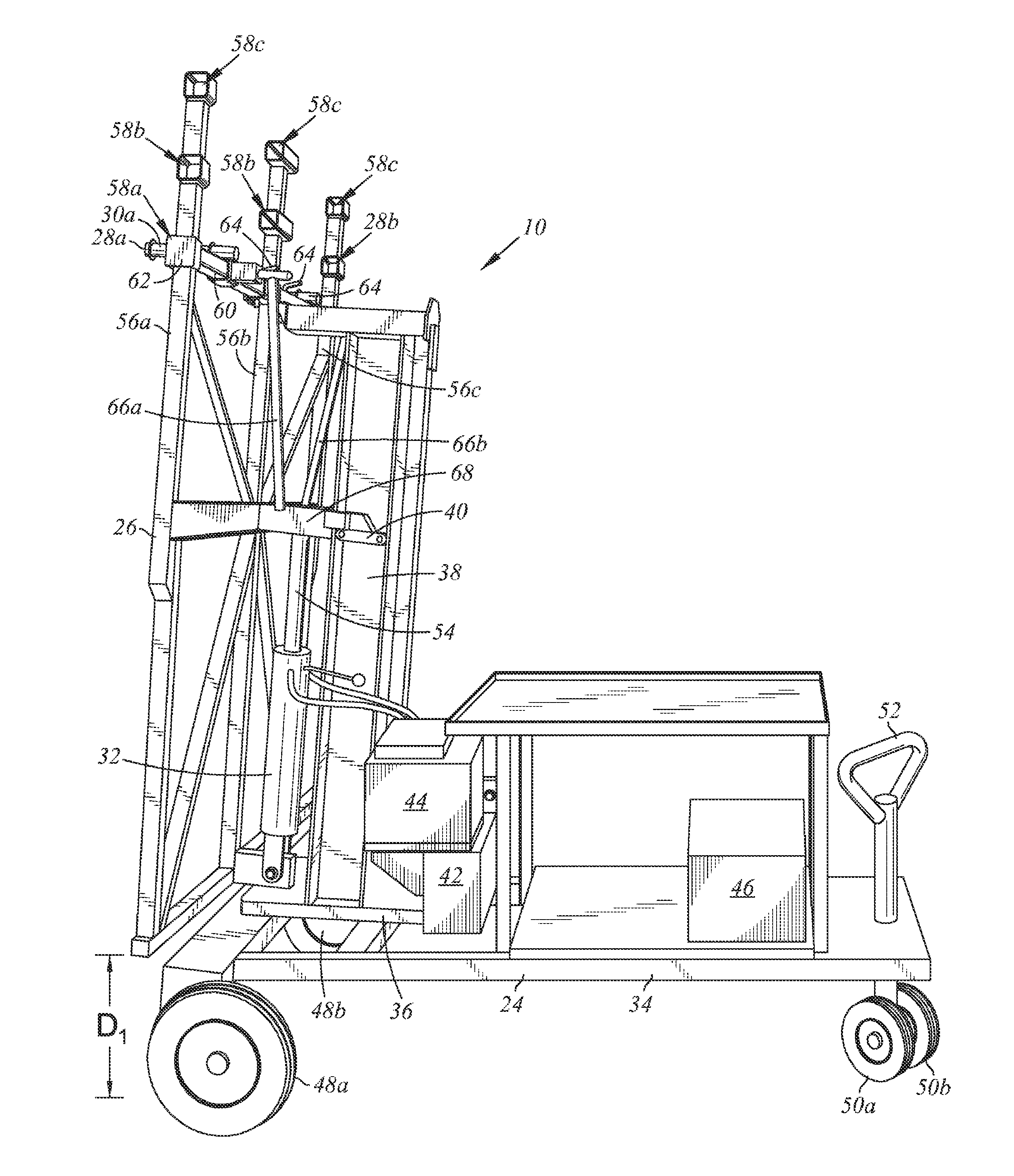

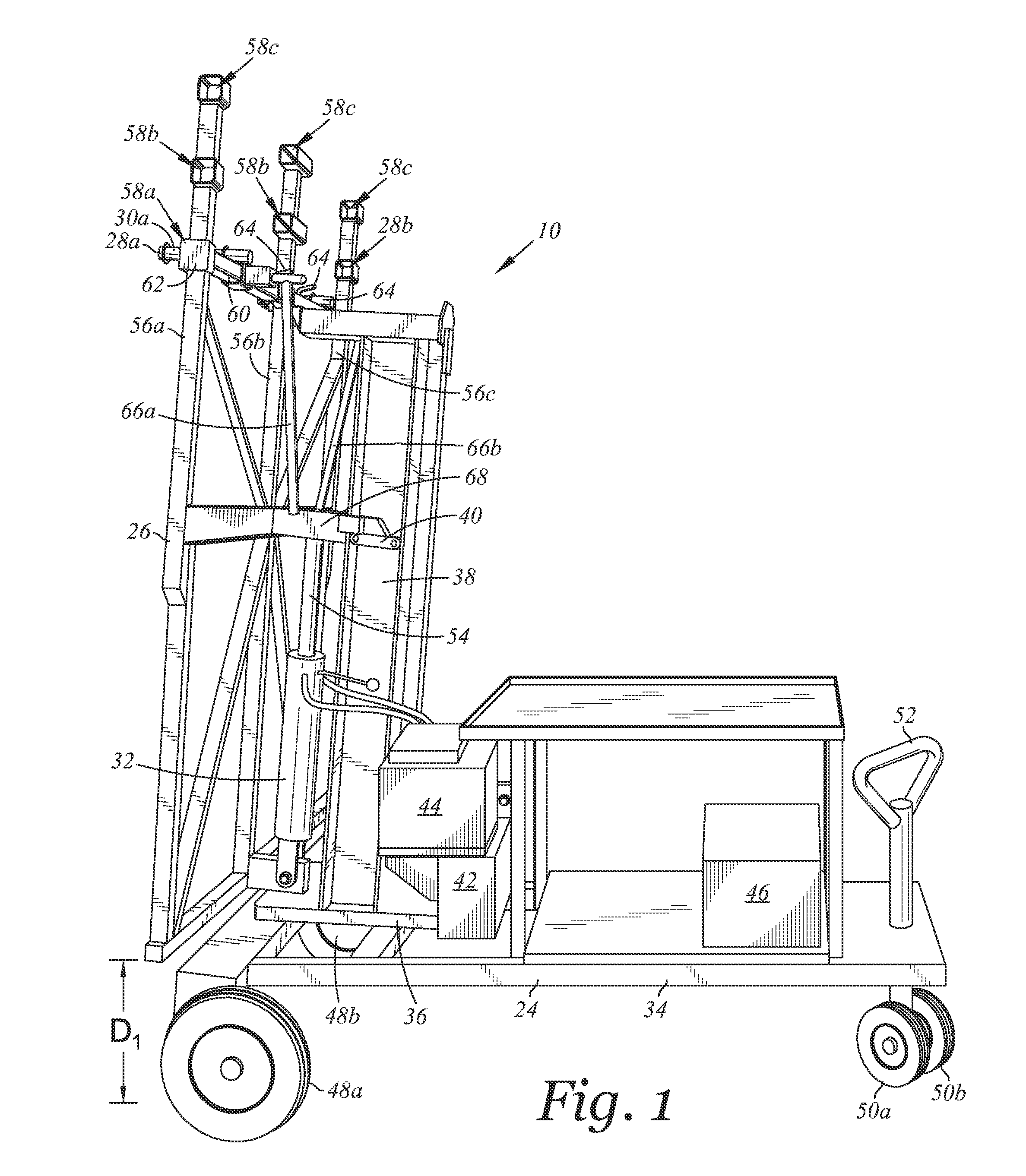

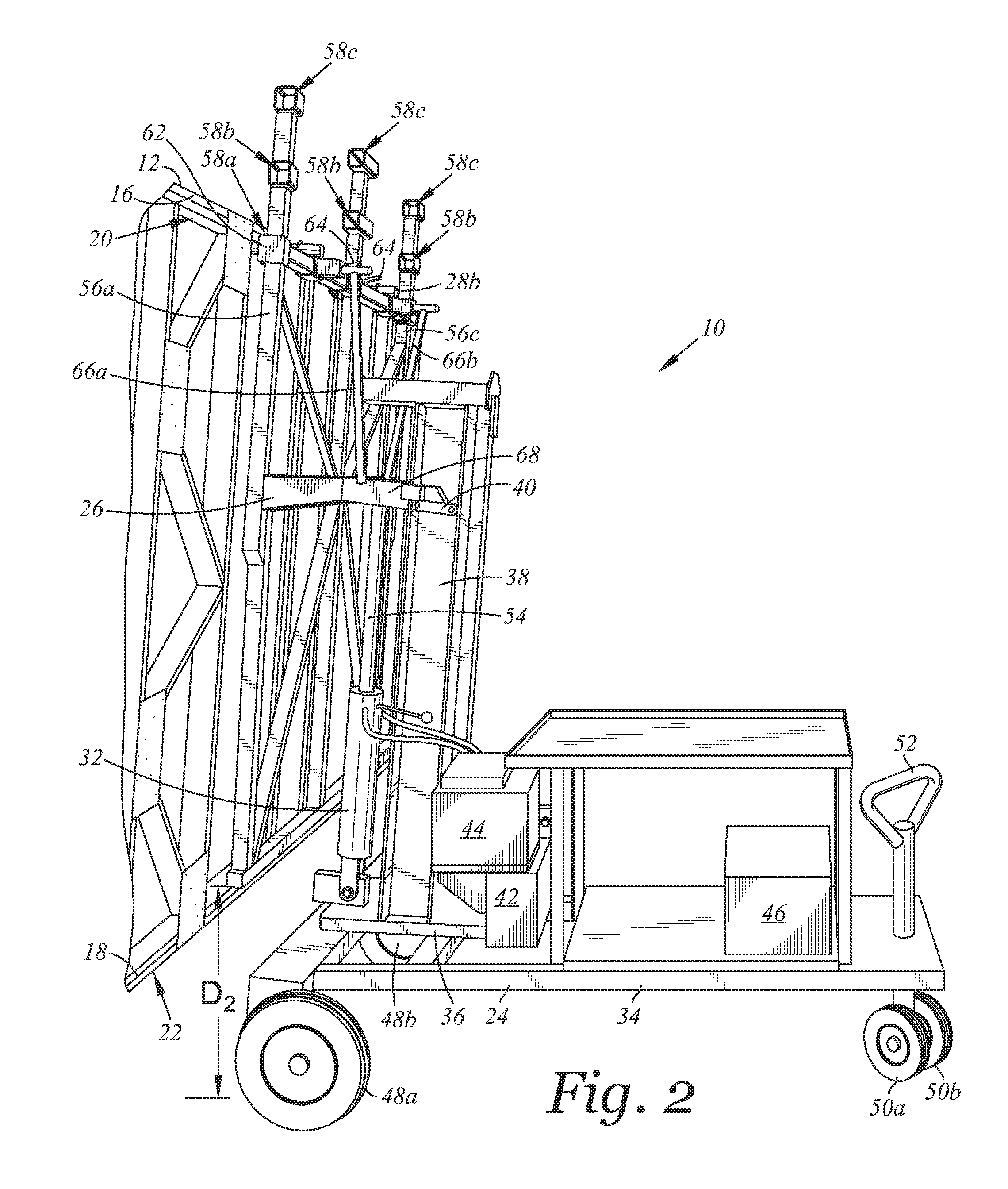

Wall lifting, transport and positioning device with roller pins

InactiveUS8966860B2Solve the quick positioningPrecise alignmentWallsPublic buildingsBraced frameActuator

A wall lifting, transport and positioning device for use with a wall section upon a worksite surface. The wall section has a top plate with a lower top plate side and a bottom plate with a lower bottom plate side. The device includes a wheeled hand cart housing, a support frame, a pair of roller pins, and a lifting actuator. Each of the roller pins including an outer cylindrical element configured to rotate relative to the support frame with the top plate being positioned in contact with the outer cylindrical element for translation of the wall section in a direction along the top plate. The lifting actuator is sized and configured to translate the roller pins upward relative to the wheeled hand cart housing with the outer cylindrical elements being positionable in contact with the lower top plate side. A method of positioning a wall section is also provided.

Owner:HOVENIER FRED E +1

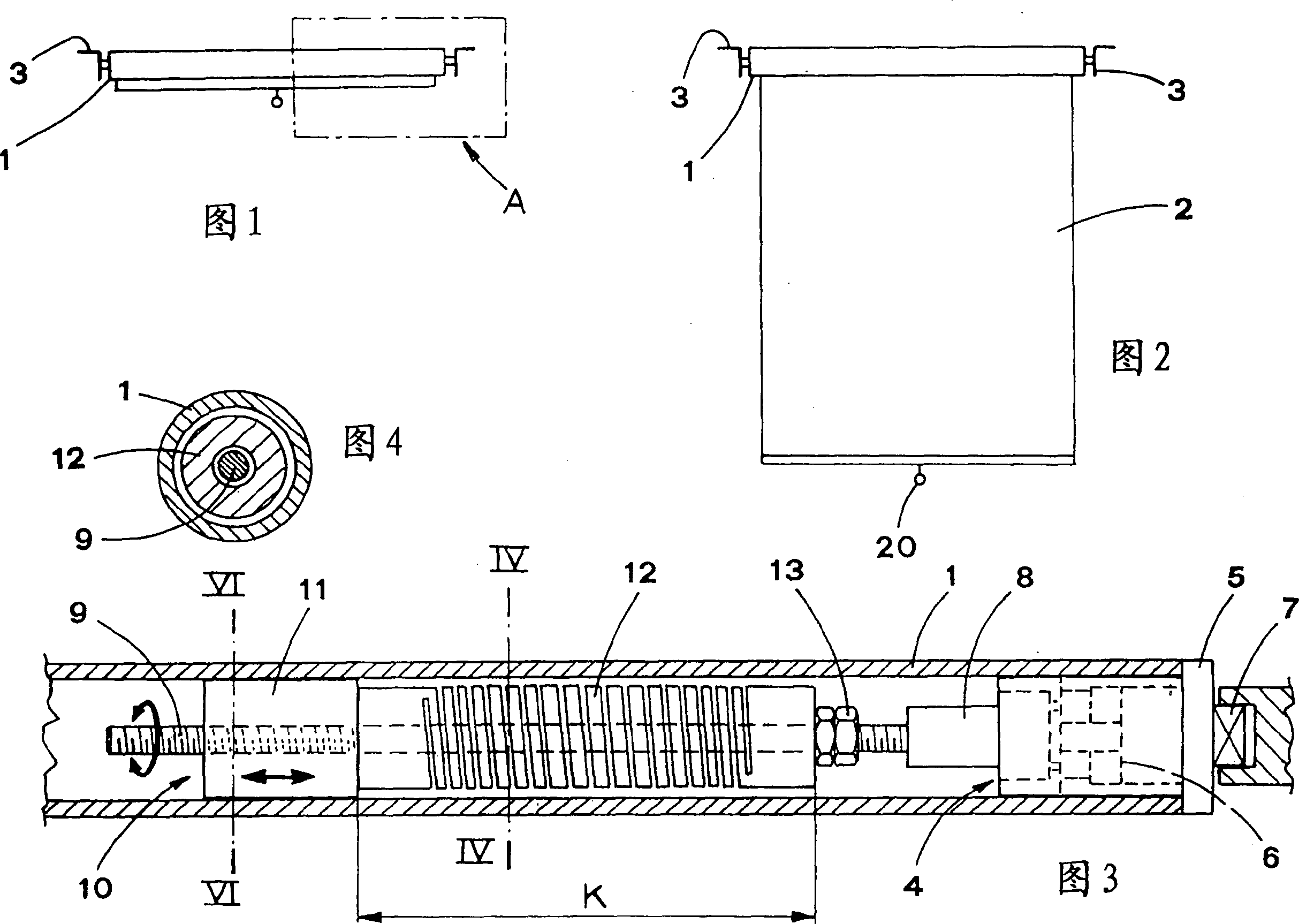

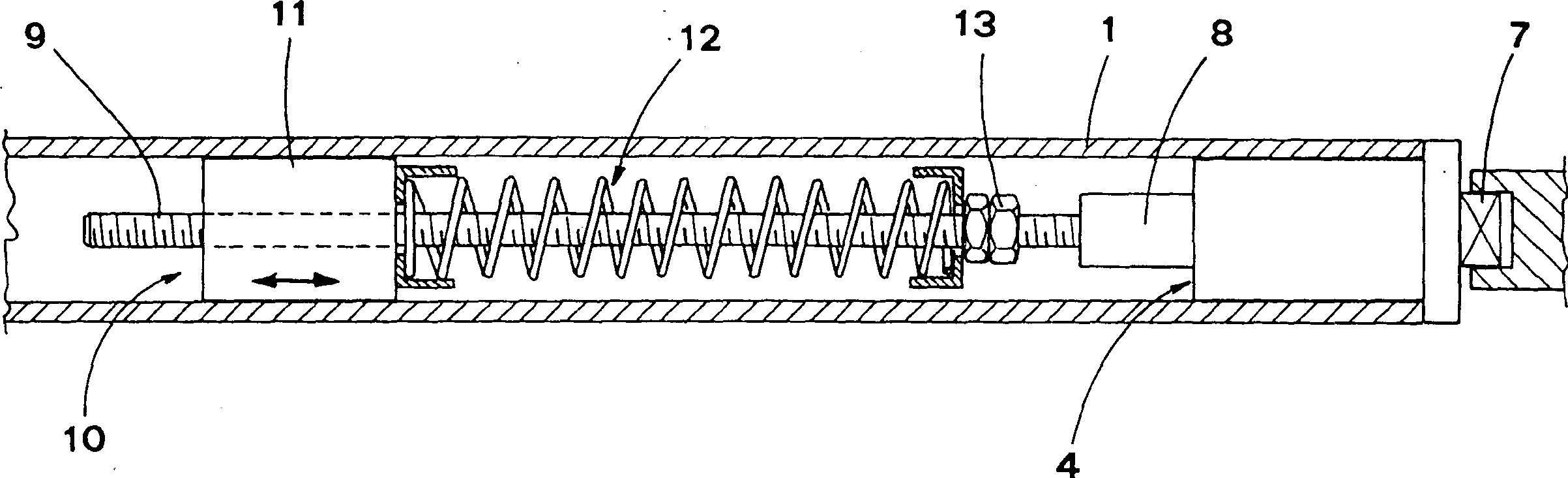

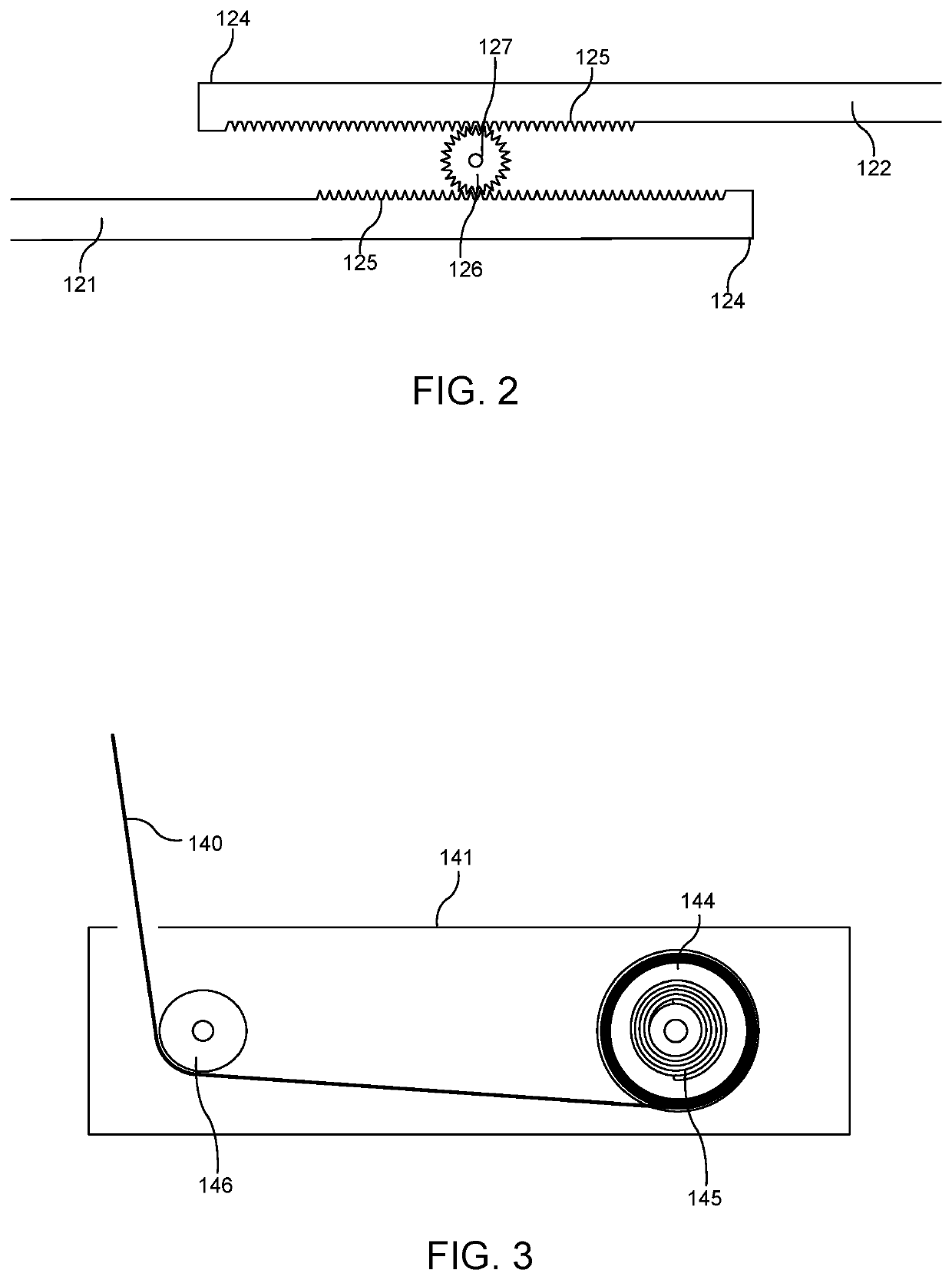

Friction device for roll-up curtains and the like

InactiveCN1266366CPrevent fallingPowerfulLight protection screensCounterweightsFriction effectReduction drive

A friction device (10), applied to roll-up curtains and the like, includes a tubular roller (1), on which the curtain (2) rolls up, and which is rotatably carried on a horizontal axis. The friction device (10) includes a threaded shaft (9), situated axially inside the roller (1) and connected to the roller (1) by interposition of an angular speed reducer group (4). A body (11), mounted sliding axially inside the roller (1), is screw-coupled with the threaded shaft (9), so as to translate axially due to the shaft (9) rotation during unrolling or rolling up of the curtain (2) on the roller (1). One or more elastic members (12), subjected to pressure or counter-thrust, are compressed, on opposite ends, between abutment means (13) and a surface of the body (11), to determine a friction effect, which varies as a function of the rotation direction of the roller (1).

Owner:GENINGS ITAL

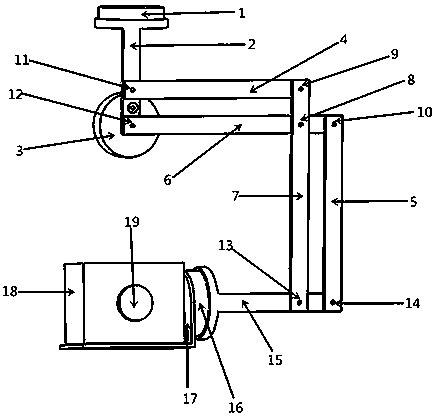

Pan-tilt structure based on double-parallelogram linkage mechanism

The invention provides a pan-tilt structure capable of achieving pitching shooting vision maximizing of shooting equipment. The pan-tilt structure comprises a heading shaft motor, a heading shaft connecting piece, a transverse roller motor, a double-parallelogram linkage mechanism, a pitching shaft connecting piece and a pitching shaft motor. The heading shaft motor is rotationally connected withthe heading shaft connecting piece. A stator part of the transverse roller motor is fixedly connected with the heading shaft connecting piece. A rotor part of the transverse roller motor is rotationally connected with one connecting rod of the double-parallelogram linkage mechanism. The transverse roller motor rotates to drive the whole double-parallelogram linkage mechanism to move parallelly. One connecting rod of the double-parallelogram linkage mechanism is rotationally connected with the heading shaft connecting piece. The pitching shaft connecting piece is rotationally connected with thedouble-parallelogram linkage mechanism. A rotor part of the pitching shaft motor is rotationally connected with the pitching shaft connecting piece. A stator part of the pitching shaft motor is fixedly connected with a bearing piece for carrying the shooting equipment.

Owner:李海活

Plate stacking and automatic beating mechanism

PendingCN107902422AIncrease spacingAccurate whereaboutsConveyorsStacking articlesGround rollerEngineering

The invention discloses a plate stacking and automatic beating mechanism. The plate stacking and automatic beating mechanism comprises a transporting belt for moving plates, and the left side and theright side of the tail end of the transporting belt are both connected with roller shafts. The roller shafts are fixedly mounted on swinging frames, and the distance between the left roller shaft andthe right roller shaft is adjusted through swinging of the swinging frame. The roller shafts and the transporting belt are consistent in height, a rail is arranged on the ground between the left roller shaft and the right roller shaft, and a trolley is arranged on the rail. A supporting rod is arranged above the rail, and a vertically-downward baffle is arranged on the supporting rod. The plates falling on the trolley are slapped, and thus the plates on the trolley are tidy and orderly.

Owner:安徽戎发冲压机器人有限公司

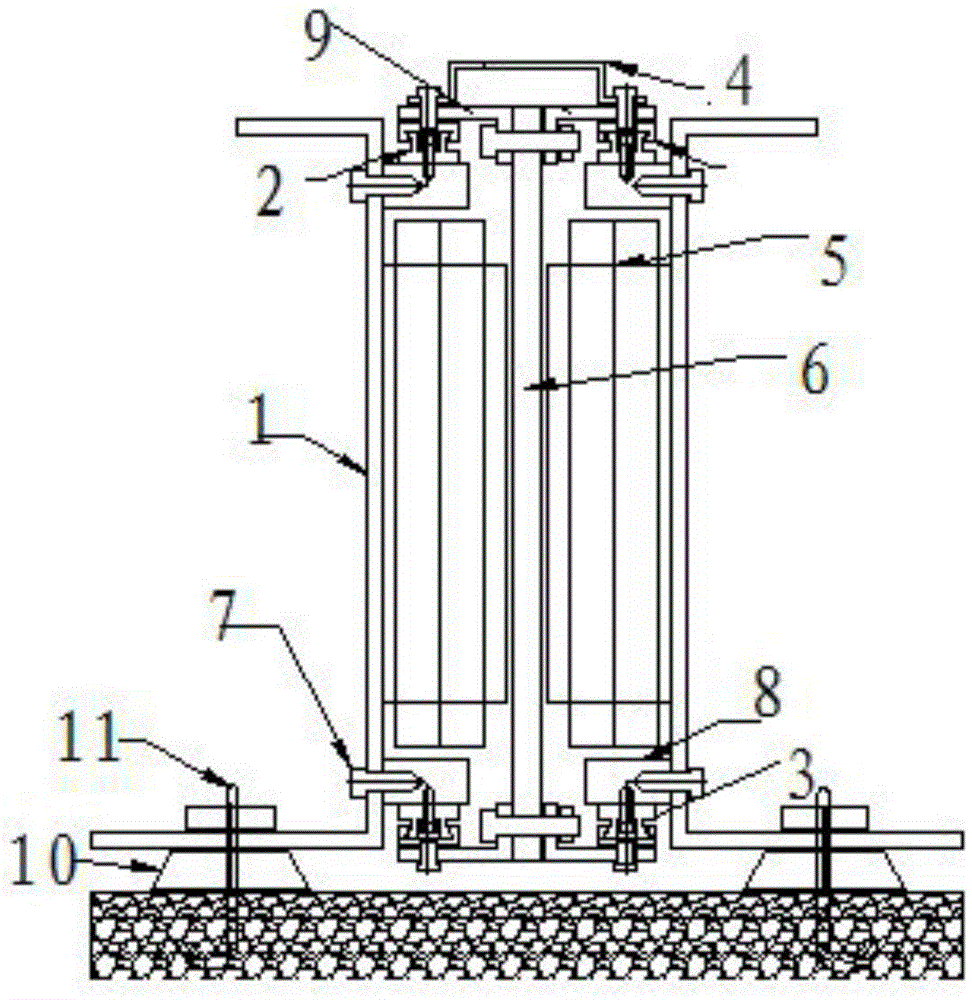

Drilling hydraulic propulsion equipment for geological exploration

ActiveCN111425151AReasonable structureHigh degree of automationDrilling rodsConstructionsMud systemsMarine engineering

The invention discloses drilling hydraulic propulsion equipment for geological exploration. The drilling hydraulic propulsion equipment comprises a carrying platform, a drilling mechanism and a mud supply mechanism, wherein the carrying platform is a traction type flat plate transport vehicle, and the flat plate transport vehicle is provided with a pair of rollers connected through a roller. The drilling hydraulic propulsion equipment has the beneficial effects that the structure is reasonable, the automation degree is high, an electrically-driven hydraulic pump is adopted as rotating and vertical power of the drilling mechanism, thus the equipment is enabled to complete drilling by means of hydraulic power, the noise is low, and the running friction is small; meanwhile, the running trackof a drill rod is limited in cooperation with a stabilizing ring and a stabilizing semi-ring to keep the drill rod rotating stably, noise and friction caused by shaking are reduced, and a matched mudsystem is arranged, so that the lubrication degree of drilling is increased, the noise is low, and the loss is reduced; and the noise and the loss in the operation process are reduced to the maximum extent through mutual cooperation of the structures, and the operation stability of the equipment is improved in multiple aspects.

Owner:孔令智

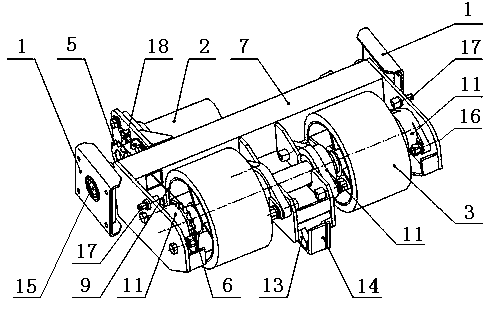

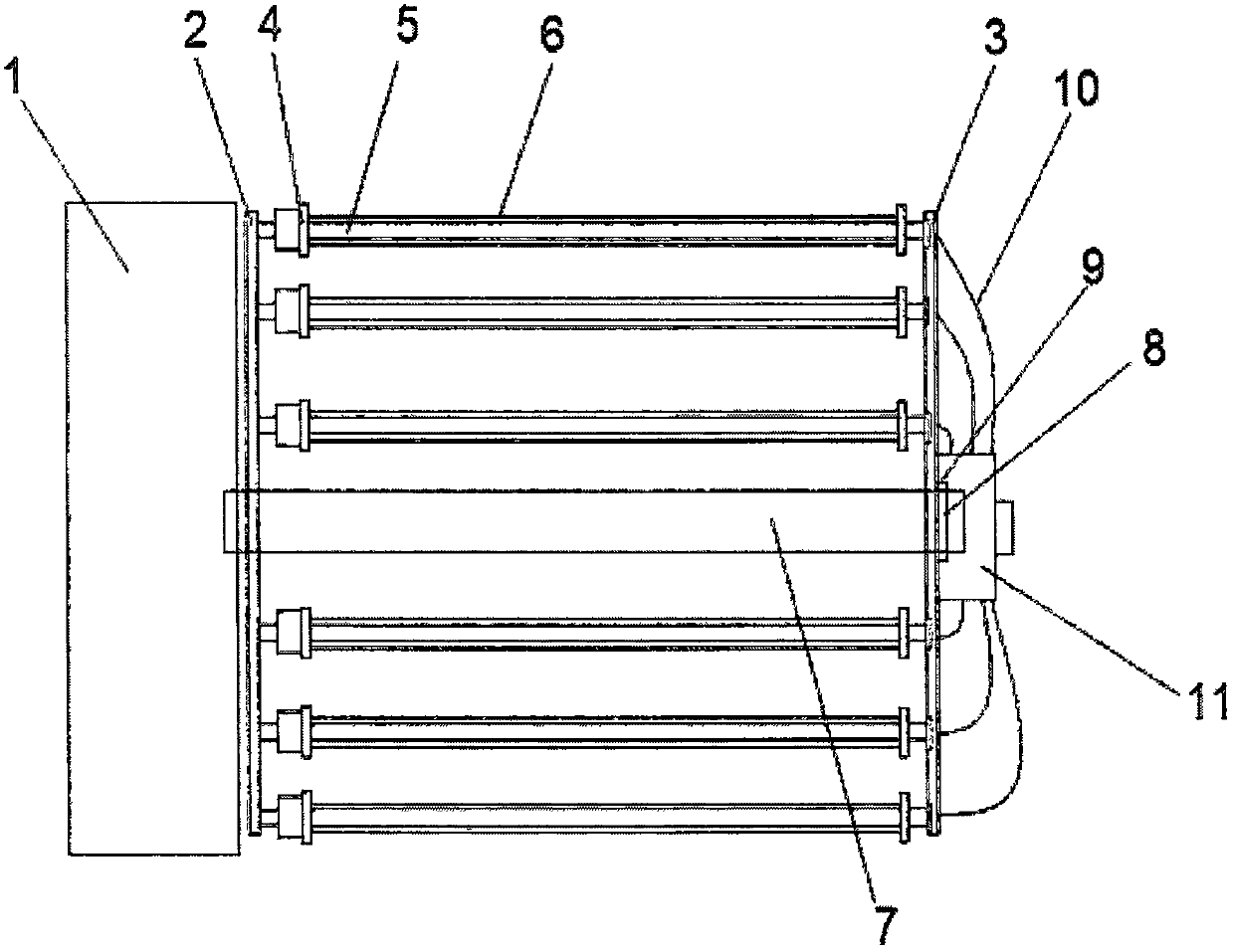

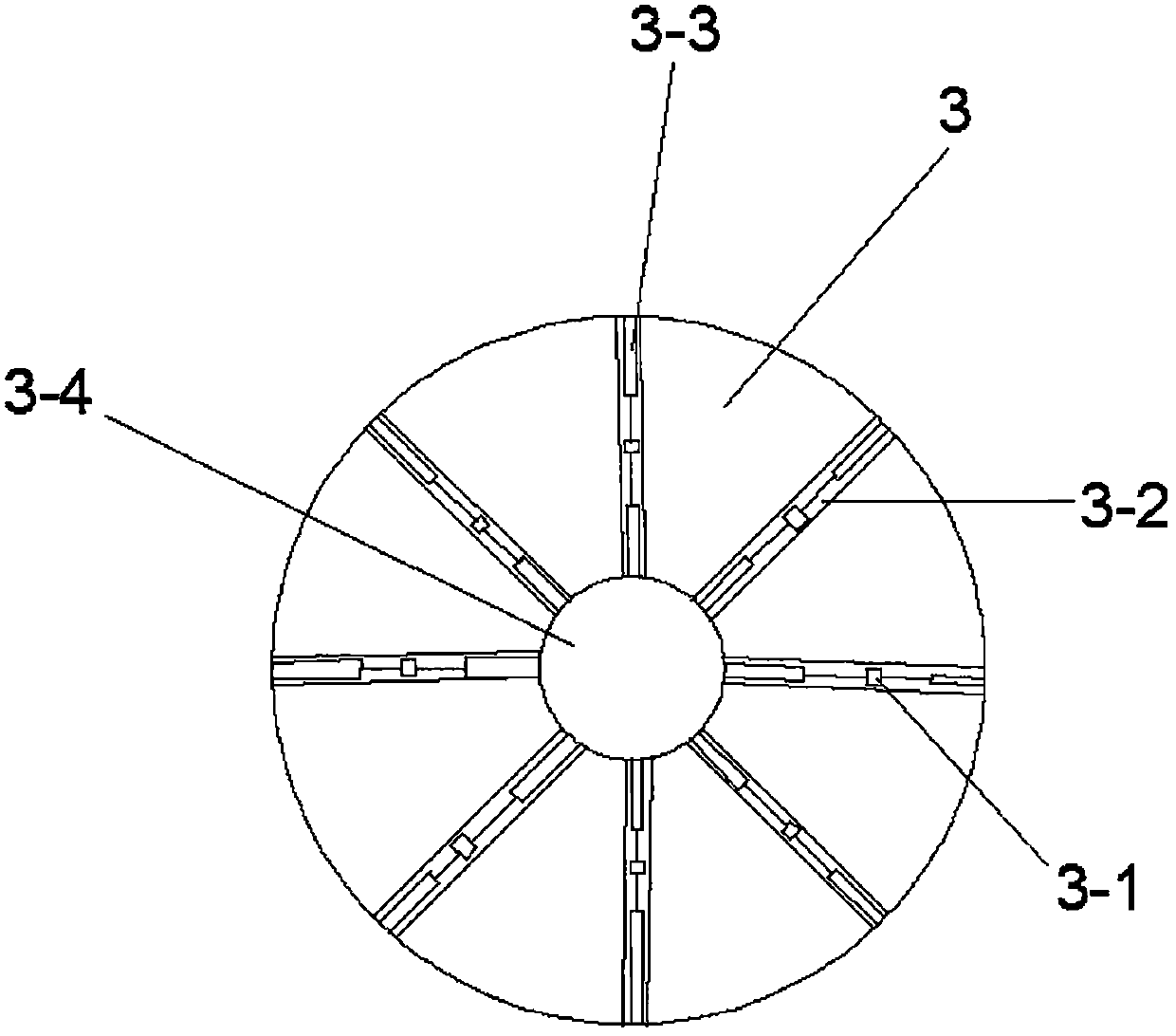

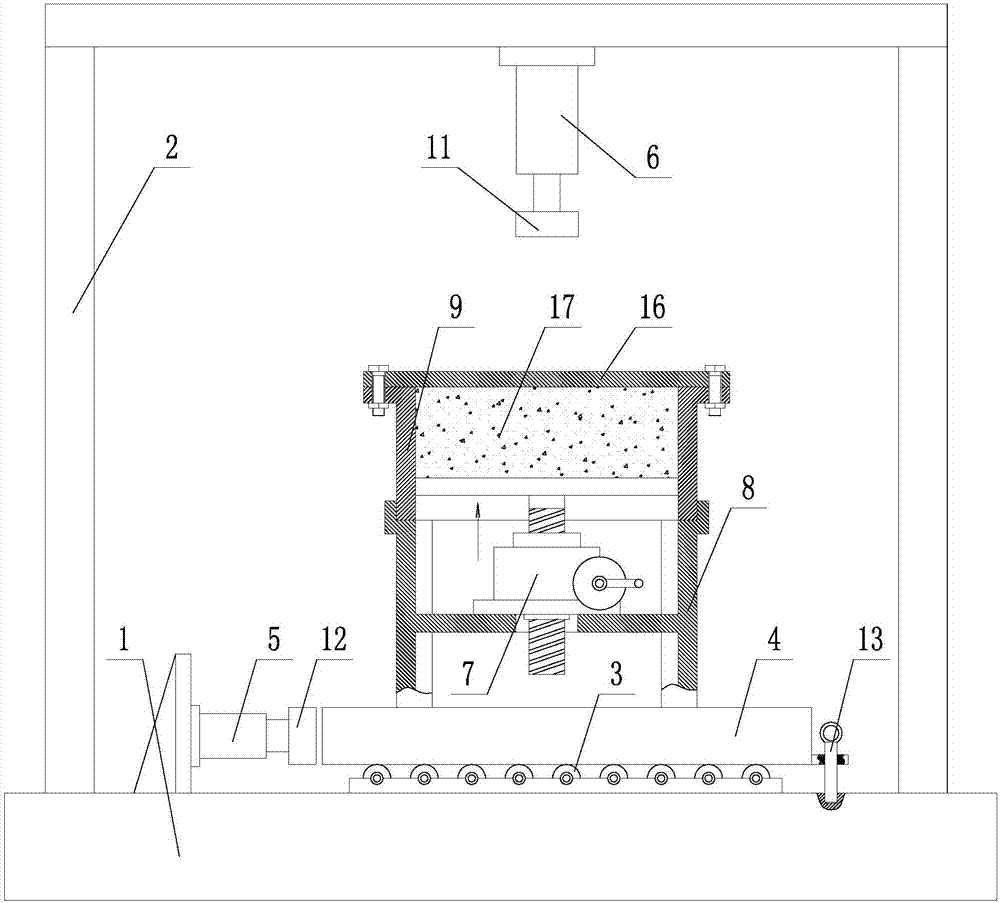

Large-diameter steel strip winding pipe die and winding method thereof

ActiveCN107790557AGuaranteed release effectImprove molding qualityShaping toolsData acquisitionEngineering

The invention discloses a large-diameter steel strip winding pipe die and a winding method of the large-diameter steel strip winding pipe die. A first supporting disc is arranged on a unit spindle, aplurality of gear discs are arranged on the first supporting disc, rollers are installed on the gear discs, and rolling shafts are installed in the rollers. The tail ends of the rollers are installedon a second supporting disc, and the two ends of each roller are connected with the two gear discs arranged on the corresponding rolling shaft correspondingly. A mandrel is arranged in the middle of the first supporting disc and the middle of the second supporting disc in a penetrating mode, a pin hole is formed in the end, penetrating out of the second supporting disc, of the mandrel, and a hingepin is inserted into the pin hole. The winding method comprises the steps that sampling is conducted through a high-frequency data acquisition card; the step length voltage value is calculated; the step length voltage value is converted into pressure data, and detection information is sent; the speed of a motor is adjusted according to the detection information, and a hydraulic rod is adjusted tocontrol the appearance structure of the die at the same time. By the adoption of the large-diameter steel strip winding pipe die and the winding method, the forming quality of pipelines is improved,the formed pipelines are closely attached to the surface of the die and easily fall off, the production efficiency and the product quality are improved, and the large-diameter steel strip winding pipedie and the winding method can be used for producing straight pipes and taper pipes.

Owner:胜利油田兴达高祥新材料有限责任公司

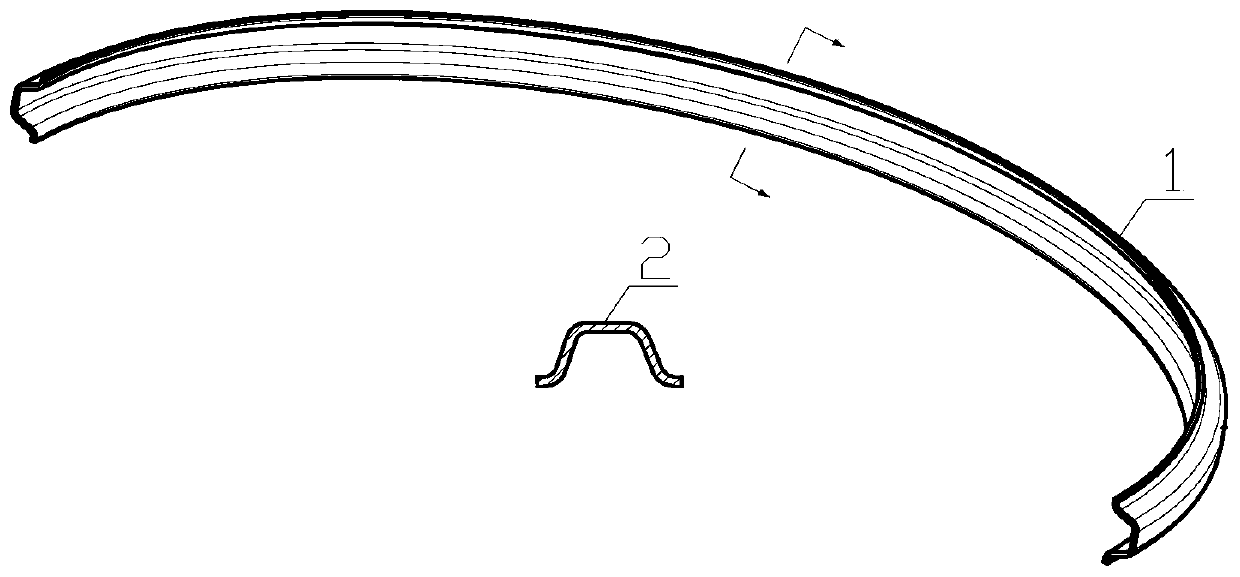

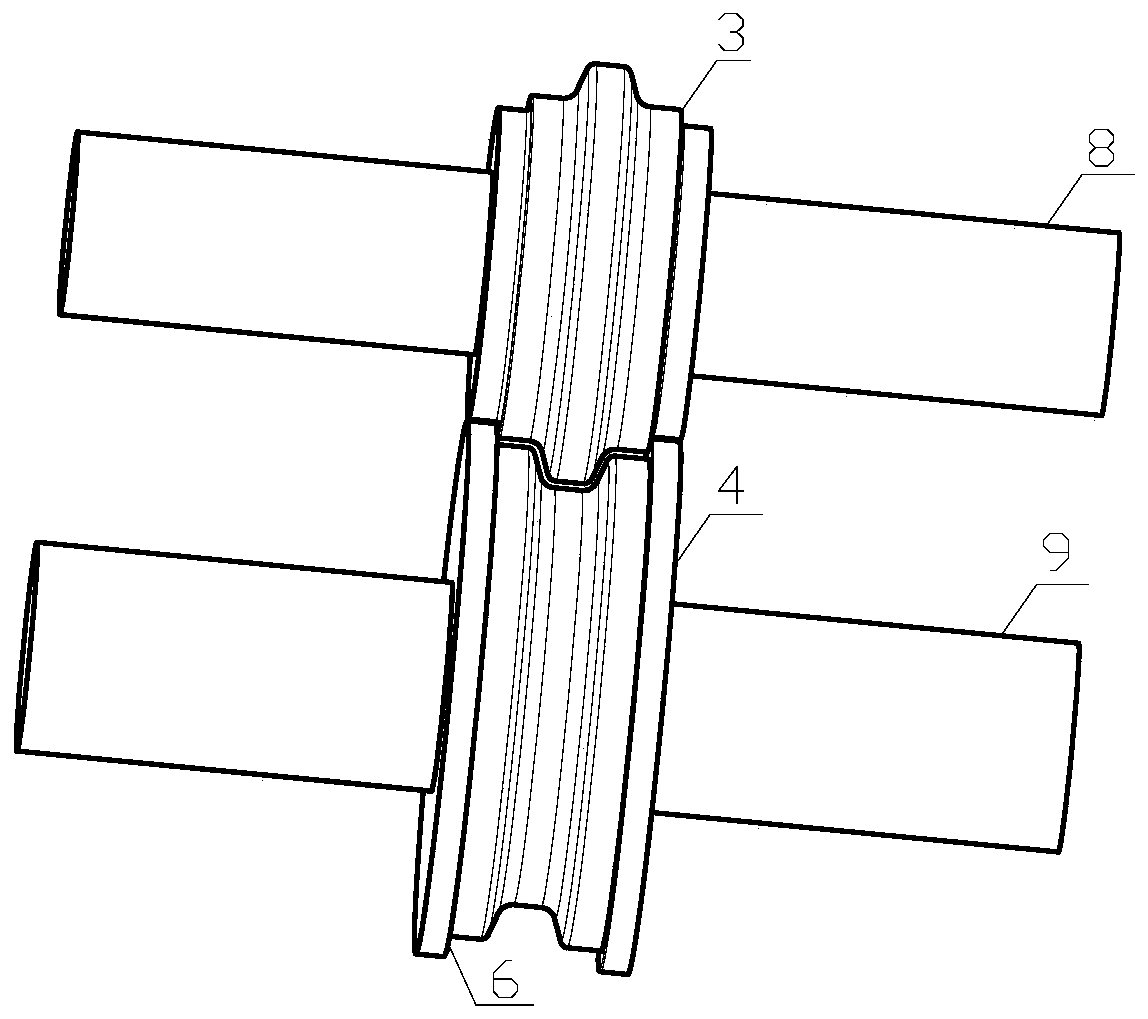

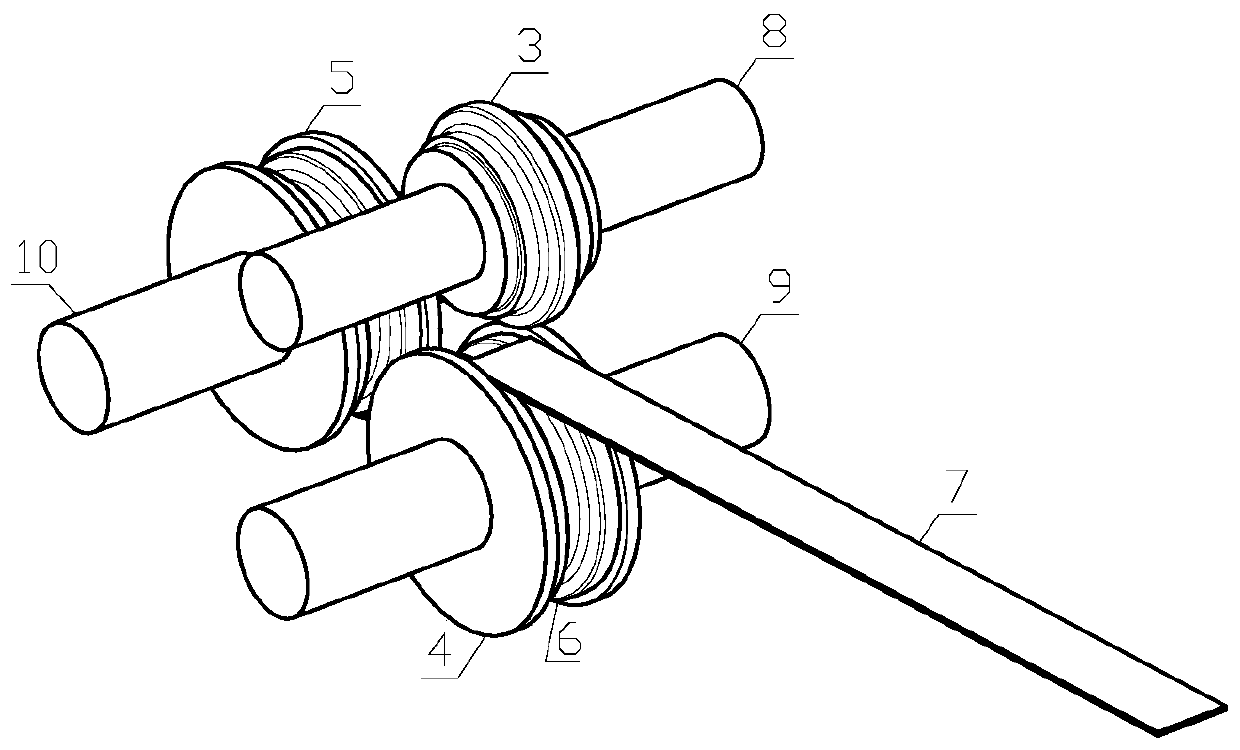

Roll bending forming die and forming method of large-curvature semi-arc-shaped pipe orifice reinforcing part

InactiveCN110639988ASimple structureSimple and convenient installation methodEngineeringStructural engineering

The invention discloses a roll bending forming die and a forming method of a large-curvature semi-arc-shaped pipe orifice reinforcing part. The forming die comprises a forming cam, a forming concave wheel and a driven concave wheel; the forming cam, the forming concave wheel and the driven concave wheel are respectively mounted on three different rollers of an asymmetric three-axis roller bendingmachine; during forming, blank positioning is carried out firstly, then the relative position relation between the forming cam, the forming concave wheel and the driven concave wheel is set, then thethree-axis roll bending device is used for forming, and finally, the pipe orifice reinforcing part passes between the three synchronous rotating rollers and continuously generates axial and longitudinal plastic bending deformation, so that the required cross-sectional shape and the radian shape are obtained.

Owner:XIAN AIRCRAFT IND GROUP

Automatic cleaning ship

The invention discloses an automatic cleaning ship comprising a ship body, a controlling device is arranged on the ship body, the ship body comprises two branch ship bodies. A propeller is arranged onthe tail portion of each branch hull, the propeller is electrically connected with the controlling device; a conveying device and a storage frame are sequentially arranged between the two branch shipbodies from front to back. The conveying device comprises a net-shaped conveying belt, a rolling shaft and a driving part for driving the rolling shaft to rotate. A plurality of rows of fishing assemblies are arranged on the net-shaped conveying belt in the moving direction. The propeller pushes the ship body to advance and steer when the automatic cleaning ship works, meanwhile, the rolling shaft is driven by the driving part to drive the net-shaped conveying belt to move, salvage is conducted through a salvage assembly, large floaters can be salvaged and conveyed into the storage frame through the net-shaped conveying belt, the net-shaped conveying belt is beneficial to draining of the floaters, and the water amount in the storage frame is reduced.

Owner:浙江舒环环境工程有限公司

Roller conveyor

PendingCN112061670AFix hard-to-deliver problemsSolve the problem of easy slippage with the rollerPackagingRoller-waysTransmission beltElectric machinery

The invention discloses a roller conveyor, and relates to the field of conveying equipment. The roller conveyor comprises a supporting component, a first conveying component is arranged on the inner side of the supporting component, and an adjusting component is arranged at one end of the supporting component. A mounting component is arranged at the bottom end of the supporting component, and a friction component is arranged on the outer wall of the first conveying component. Through the arrangement of conveying belts, a motor, a supporting seat, an adjusting plate and a rubber cone, the supporting seat and an adjusting seat are clamped in the adjusting plate, an object with an irregular shape is placed on a roller way, the two sides of the object are clamped on the two conveying belts, and the motor drives the conveying belts to convey through two rolling shafts. When the conveying belts move, the object is driven by a plurality of rubber blocks on the conveying belts to move on the roller way, so that the irregular object can be conveyed under the driving of the two conveying belts and a plurality of rollers. Thus, the problem that the object with the irregular shape is difficultto convey is effectively solved.

Owner:浙江八八机械有限公司

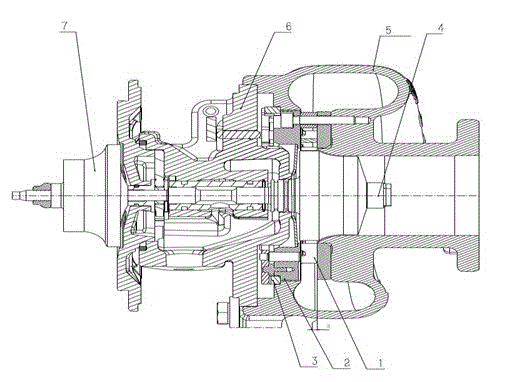

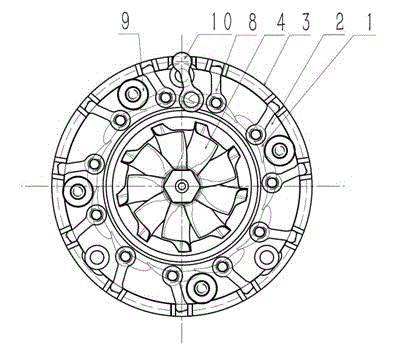

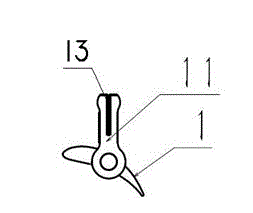

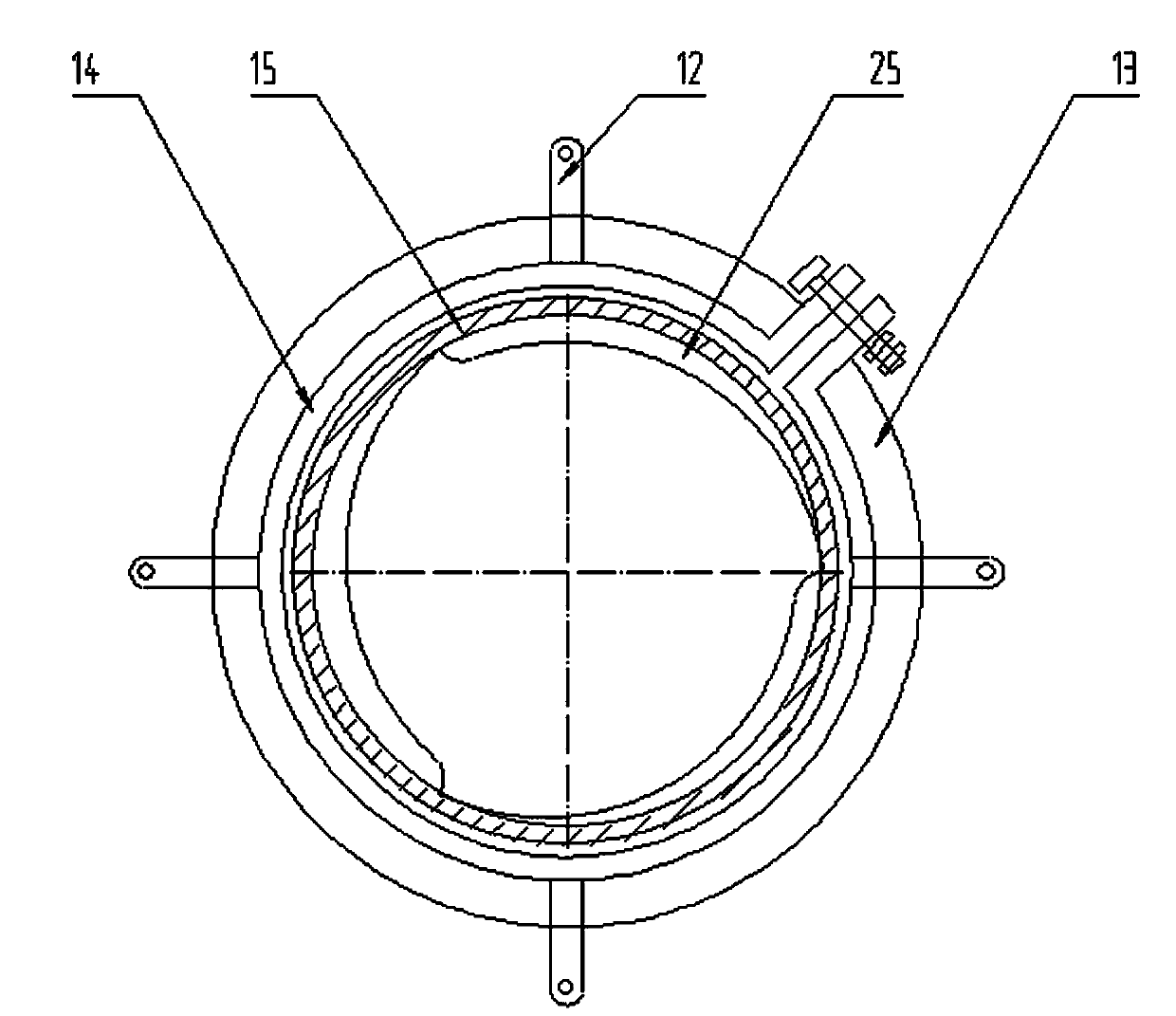

Adjustable nozzle for turbosupercharger

InactiveCN103147846ASimple structureSignificant improvementInternal combustion piston enginesEngine componentsTurbochargerRolleron

The invention provides an adjustable nozzle that can improve the reaction sensitivity of a supercharged engine effectively and is applicable to a variable turbosupercharger. The adjustable nozzle comprises guide blades, a blade seat, a driving disk, a driving rocker arm and driven rocker arms, wherein the guide blades are mounted on the blade seat; the driving disk and the blade seat are mounted coaxially through a plurality of rollers; one end of each driven rocker arm and the guide blades are mounted coaxially; the other ends of the driven rocker arms are arranged in a notch of the driving disk in a clamping manner; when the driving rocker arm drives the driving disk to rotate, the driving disk transmits rotary motion to the driven rocker arms through the rollers; the driven rocker arms drive the guide blades to rotate, and are elastic arms; and one end of each elastic arm is elastically compressed and arranged in the notch of the driving disk in a clamping manner, and contacted with the driving disk all the time. The adjustable nozzle is simple and easy in structure, and an effect of technical performance improvement is remarkable.

Owner:汉美综合科技(常州)有限公司

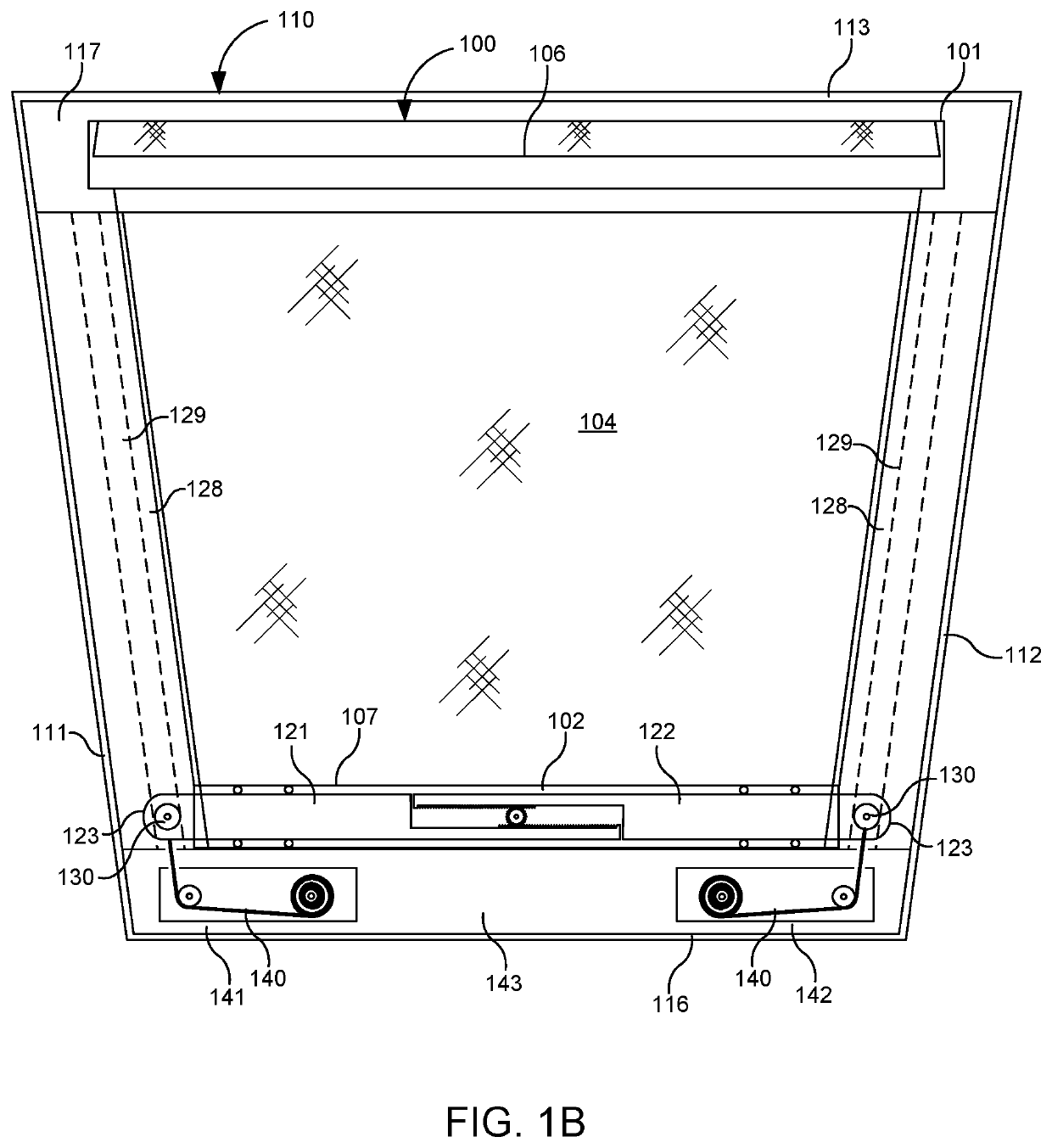

Roller shade for non-rectangular windows

A roller shade adapted to be installed in a non-rectangular structural opening comprising a roller tube, a shade material, a hem bar, a shade drive unit adapted to rotate the roller tube, and a pair of longitudinal side channels adapted to be attached to the sides of the structural opening. The shade material comprises a shape that corresponds to the shape of the structural opening to substantially cover thereof. The hem bar may be extendable and may comprise a pair of wheels at its opposite terminal ends. Each wheel is adapted to be retained by and travel within one of the longitudinal channels which are adapted to guide the hem bar assembly along the side jambs and control an extension of the extendable hem bar as the shade material is rolled on or unrolled from the roller tube and the distance between the side jambs changes. The roller shade may further comprise a pair of tension modules adapted to be attached opposite from the roller tube. Each tension module comprises a retractable cable attached to the hem bar proximate to one of the wheels to provide tension on the hem bar assembly.

Owner:CRESTRON ELECTRONICS

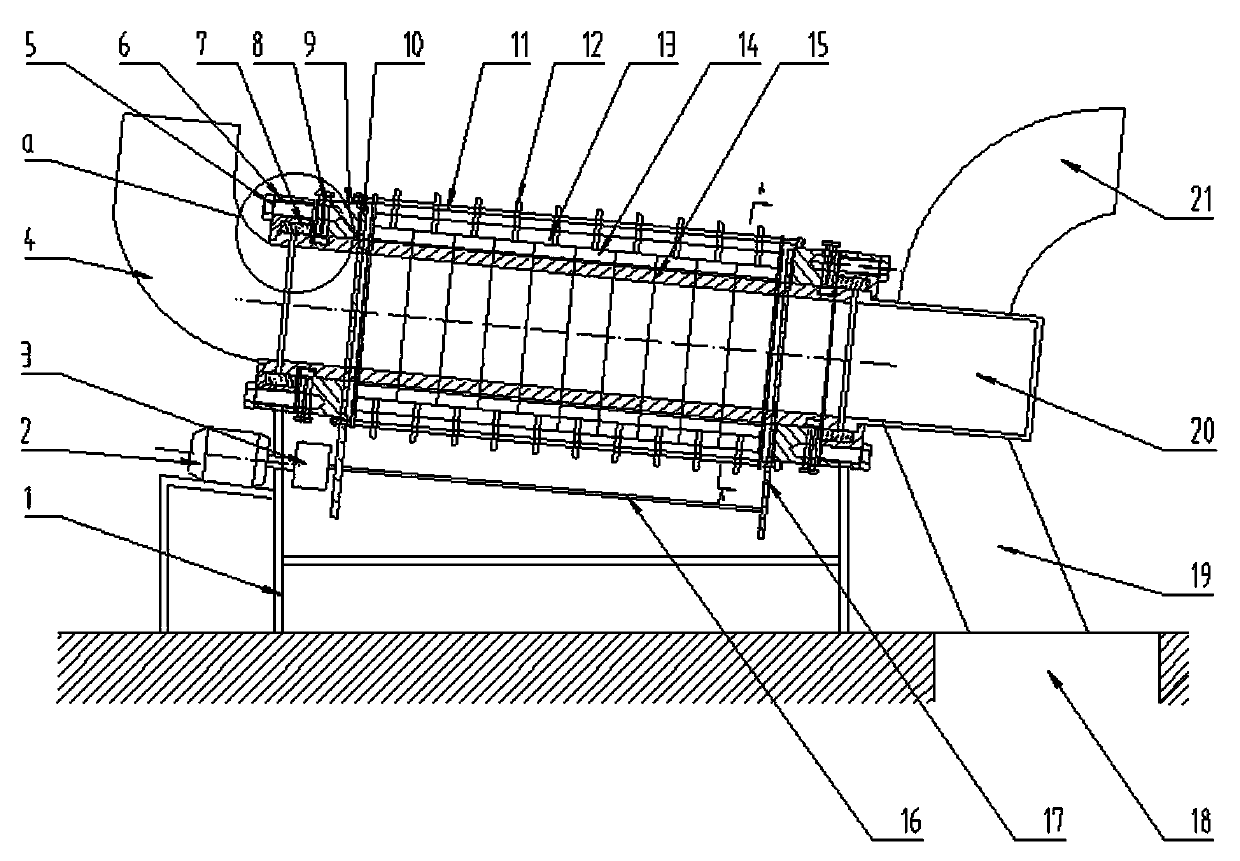

Biomass dry-distillation, pyrolysis and gasification device

InactiveCN103555350ADry distillationReduce manufacturing costChemical industryBiofuelsElectric machineDrive shaft

The invention discloses a biomass dry-distillation, pyrolysis and gasification device, comprising an oblique cylinder; the cylinder is provided with a feed pipe and a material receiving cavity, wherein the material receiving cavity is provided with an air outlet pipe and a deslagging pipe, the outer wall of the cylinder is provided with a cylinder gear, a transmission shaft connected with a driving motor and a gearbox is arranged below the cylinder, the transmission shaft is provided with a transmission shaft gear, two ends of the cylinder are provided with clamping slots, a plurality of rollers are arranged in the clamping slots, and each roller is wrapped by a roller adjustment pressing ring; two ends of the cylinder are provided with the material receiving cavity and the feed pipe and are respectively connected with an inner flange ring and an outer flange ring through bolts, and the inner flange ring is provided with an oiling type adjusting bolt; the oiling type adjusting bolt props against the roller adjustment pressing rings; the joint part between the outer flange ring and the cylinder is provided with a packing strip; a spiral groove plate is arranged in the cylinder, a cross bar is arranged outside the cylinder, the cross bar is connected with a suspender, the suspender is connected with a plurality of electric heating coils, the cylinder is wrapped by the electric hearing coils, and the electric heating coils are further wrapped by insulating layers. According to the biomass dry-distillation, pyrolysis and gasification device, energy is saved, consumption is reduced, and production cost of enterprises is greatly reduced.

Owner:叶安生

A mechanical lifting type construction machinery transfer device

The invention discloses a mechanical lifting type construction machinery transfer device, which comprises a main frame, the rear end of the main frame is provided with an equipment inlet, and the lower end of the main frame is uniformly covered with rollers, and the left and right ends of the rollers are It forms a bearing connection structure with the left and right sides of the main frame. The upper end of the right side wall behind the main frame is fixedly installed with a mounting seat, and the inner side of the mounting seat forms a hinged structure with the right end of the movable stop rod, and the left side wall at the rear of the main frame The upper end of the main frame is fixedly installed with a fixed bayonet, and the left side of the front surface of the main body frame is fixedly installed with a motor, and the shaft end of the motor and the left end of the transmission shaft form a fixed connection structure. The mechanical lifting type construction machinery transfer device can easily and quickly place the construction machinery on the transfer device for transportation, and the operation steps are simple and convenient, reduce the labor intensity of the staff, and can adapt to relatively complex terrain.

Owner:湖南慧盟重工科技有限公司

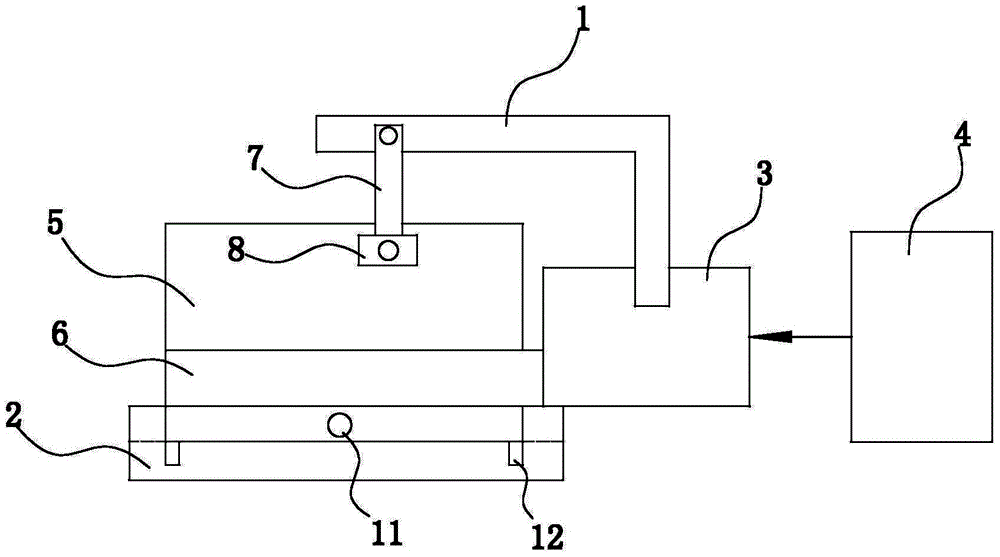

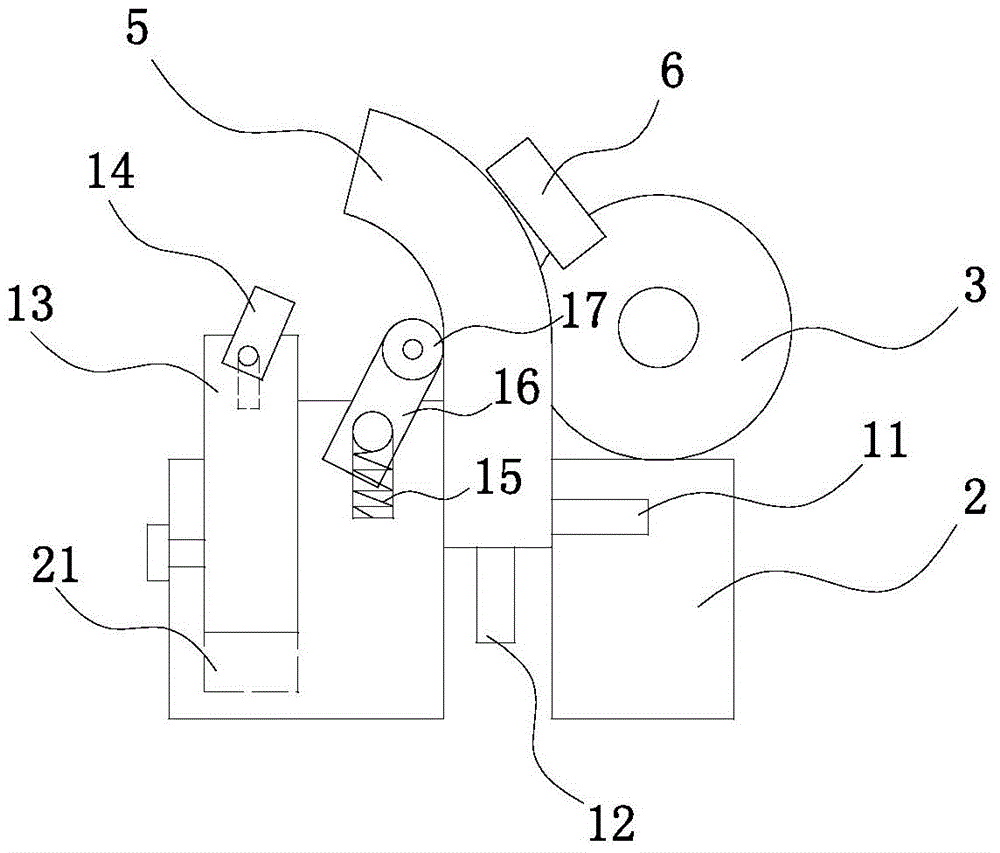

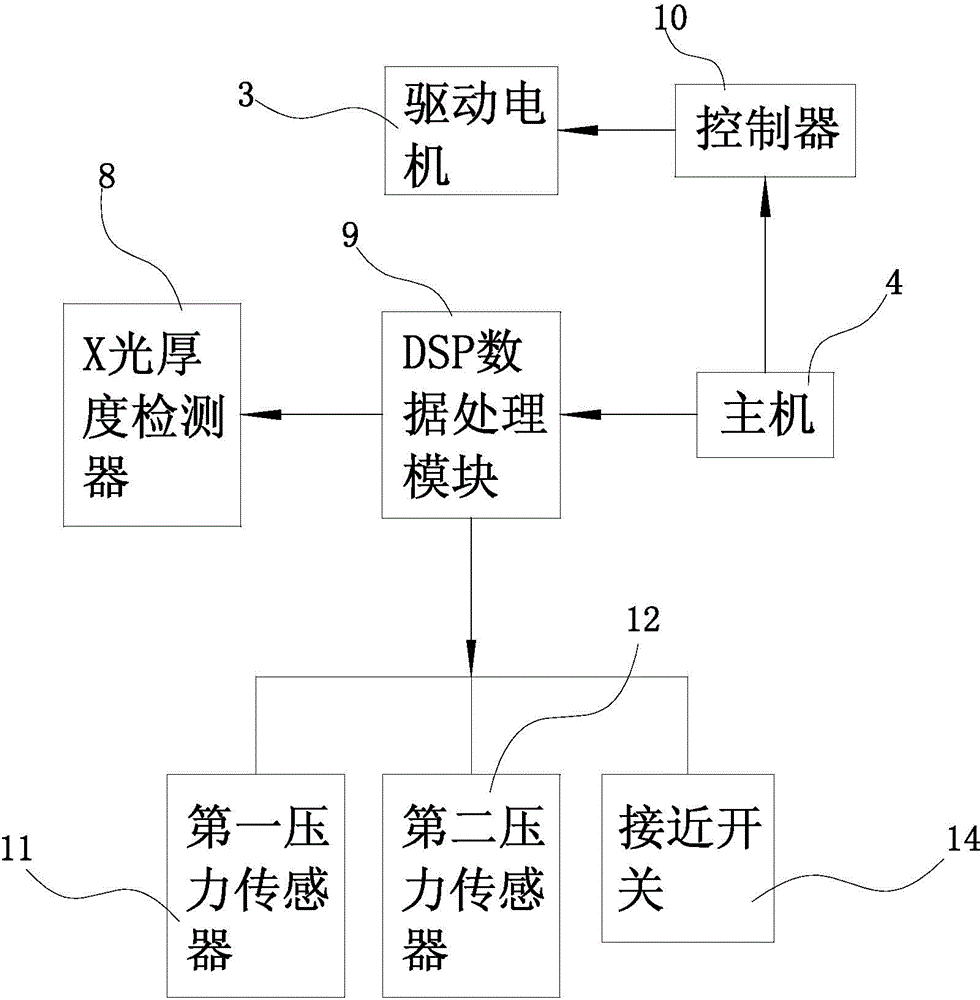

Bending device and method based on rolling bending and torque controlling

InactiveCN104942085AAvoid influencePrevent looseningMetal-working feeding devicesMetal working apparatusAutomatic controlX-ray

The invention relates to a bending device and method based on rolling bending and torque controlling. The bending device comprises a driving motor, a clamping fixing seat and a host which are installed on a rack; a bending shaft is installed on the driving motor, and a work piece is arranged on the clamping fixing seat; the bending device further comprises an X-ray thickness detector which is installed on the rack through a support, and a proximity switch, a first pressure sensor, a second pressure sensor and a roller which are installed on the clamping fixing seat; the first pressure sensor and the second pressure sensor are located on the side face and the bottom face of the work piece respectively, and the roller is located on the concave face side of the work piece. According to the bending device and method, the pressure sensors are adopted to control the clamping force, and therefore excessive deformation and looseness of sheet metal are avoided; bending is performed with the most suitable torque, and therefore the machining quality is improved; the proximity switch is arranged to automatically control the bending angel, and therefore excessive bending is prevented; the inner concave face of the work piece is rolled by the roller, and therefore cracks and burrs at the concave face are decreased.

Owner:SUZHOU BIANTONG SENSING TECH

Device and method for measuring frictional angle of interface of retaining wall and contact soil

PendingCN107036914AIncrease flexibilityThe value of the interface friction angle is close toMaterial strength using steady shearing forcesClimate change adaptationFriction angleRolleron

The invention relates to a device and a method for measuring a frictional angle of an interface of a retaining wall and contact soil. The device comprises a base, a counter-force frame, a roller slide rail, a bearing sliding table, a shear force applying cylinder, a loading force applying cylinder, a screw rod lifter, a screw rod lifter mounting rack, a retaining wall sample shearing box and a contact soil sample shearing box; the counter-force frame and the roller slide rail are fixedly arranged on the base; the loading force applying cylinder is vertically fixed at the top end of the counter-force frame; the shear force applying cylinder is horizontally and fixedly arranged on the base; pressure sensors are arranged at the ends of piston rods of the loading force applying cylinder and the shear force applying cylinder; the contact soil sample shearing box, the retaining wall sample shearing box, the screw rod lifter mounting rack, the bearing sliding table and the roller slide rail are arranged from top to bottom on the base. The method comprises the following steps: preparing the sample; mounting the sample; applying a loading force till reaching a preset value; applying a shear force to the contact soil sample, shearing and damaging; repeating multiple sets of shear damaging tests; and fitting the straight line of the loading force and the shear force, wherein an inclined angle of a fitting straight line is the frictional angle of the interface.

Owner:LIAONING TECHNICAL UNIVERSITY

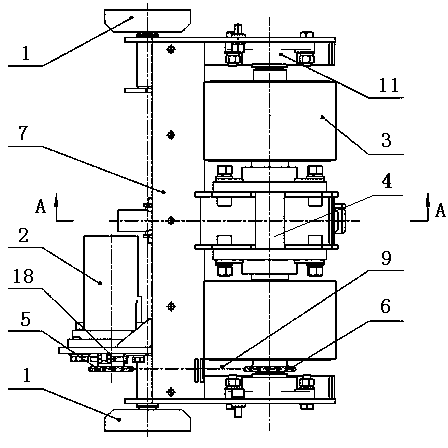

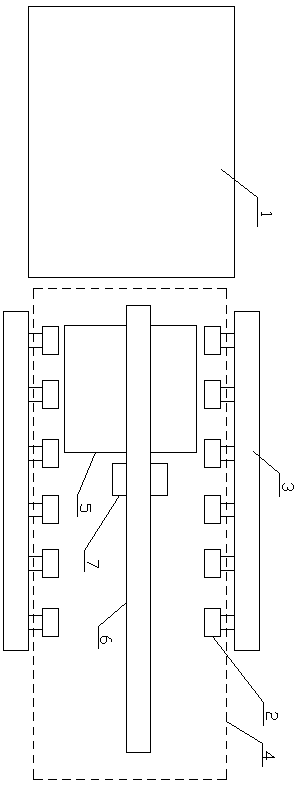

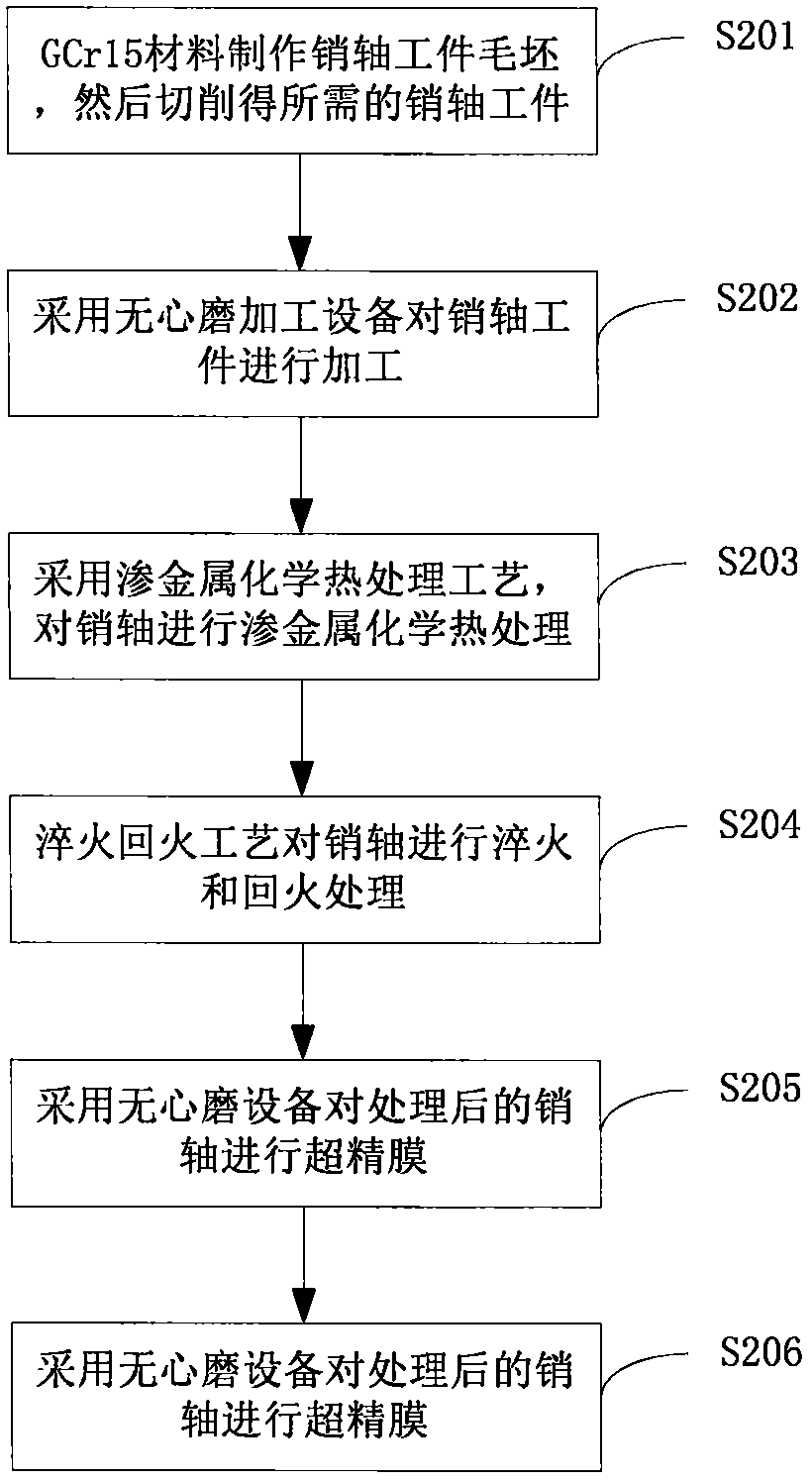

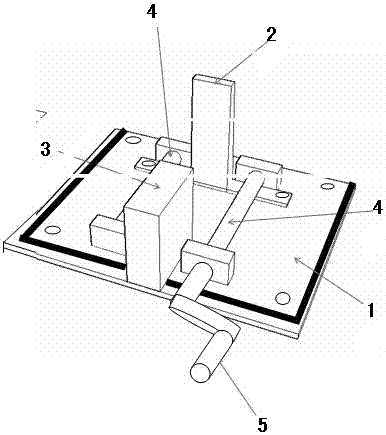

Multi-stage cylinder line marking and drilling safety tool, multi-stage cylinder line marking method and multi-stage cylinder drilling machining method

PendingCN107052862AClamp firmlyImprove securityMeasurement/indication equipmentsOther workshop equipmentStructural engineeringRolleron

The invention belongs to machining devices, and particularly relates to a multi-stage cylinder line marking and drilling safety tool, a multi-stage cylinder line marking method and a multi-stage cylinder drilling machining method. The multi-stage cylinder line marking and drilling safety tool comprises a horizontal base plate. A vertical supporting baffle is fixedly installed on the front portion of the base plate. A clamping mechanism which faces the supporting baffle and can horizontally move forwards and backwards is installed on the rear portion of the base plate. A pair of horizontal rolling shafts which are parallel to each other are installed on the two sides of the base plate, the two ends of each horizontal rolling shaft are installed on supporting bases through bearings, and a rocking handle which can drive the horizontal rolling shafts to rotate is installed at the end of at least one horizontal rolling shaft. The external circumference of a cylindrical workpiece can be installed between the two horizontal rolling shafts and is tangent with the horizontal rolling shafts, and the two axial ends of the cylindrical workpiece can be axially clamped and fixed or released by the clamping mechanism and the supporting baffle facing the clamping mechanism. The multi-stage cylinder line marking and drilling safety tool is simple in structure, high in clamping accuracy, good in stability and high in safety, and convenient to operate and firm to clamp.

Owner:JIANGYIN GIANSUN MOLD

Mechanical lifting type engineering machinery transfer device

The invention discloses a mechanical lifting type engineering machinery transfer device which comprises a main body frame, an equipment inlet is formed in the rear end of the main body frame, rollingshafts are evenly distributed at the lower end of the main body frame, and the left ends and the right ends of the rolling shafts and the left side and the right side of the main body frame form bearing connecting structures; a mounting seat is fixedly mounted at the upper end of the right side wall behind the main body frame, the inner side of the mounting seat and the right end of the movable stop lever form a hinged structure, a fixed bayonet is fixedly mounted at the upper end of the left side wall behind the main body frame, and a motor is fixedly mounted on the left side of the front endsurface of the main body frame; and the shaft end of the motor and the left end of the transmission shaft form a fixed connection structure. According to the mechanical lifting type engineering machinery transfer device, engineering machinery can be conveniently, simply and rapidly placed on the transfer device to be carried, the operation steps are simple and convenient, the labor intensity of workers is reduced, and the mechanical lifting type engineering machinery transfer device can adapt to complex terrains.

Owner:湖南慧盟重工科技有限公司

An automatic real-time monitoring device for deformation of ultra-deep underground diaphragm wall and its working method

ActiveCN110258664BGood transmission effectImprove work performanceFoundation testingLoad-engaging elementsSlurry wallSlide plate

The invention discloses an automatic real-time monitoring device for the deformation of an ultra-deep underground continuous wall, which comprises a wire frame, a fixing frame is installed on the outside of the wire frame, a side plate is installed on the outside of the wire frame, and a roller, and the roller is located at the bottom position on the wire rack, a slide plate is installed on one end of the roller shaft, and a lifting hook is arranged on the outside of the present invention, which facilitates the lifting effect of the present invention through the lifting hook, and avoids road conditions in the construction environment. Under bad conditions, the situation of moving by the crane reduces the problem that the present invention cannot walk due to the poor road surface during the working process. Carrying out relatively easy moving work increases the moving ability of the present invention, and the roller is provided with a slide plate and a protective frame, which can protect the roller through the protective frame and increase the working capacity of the roller.

Owner:GUANGDONG YUANTIAN ENG

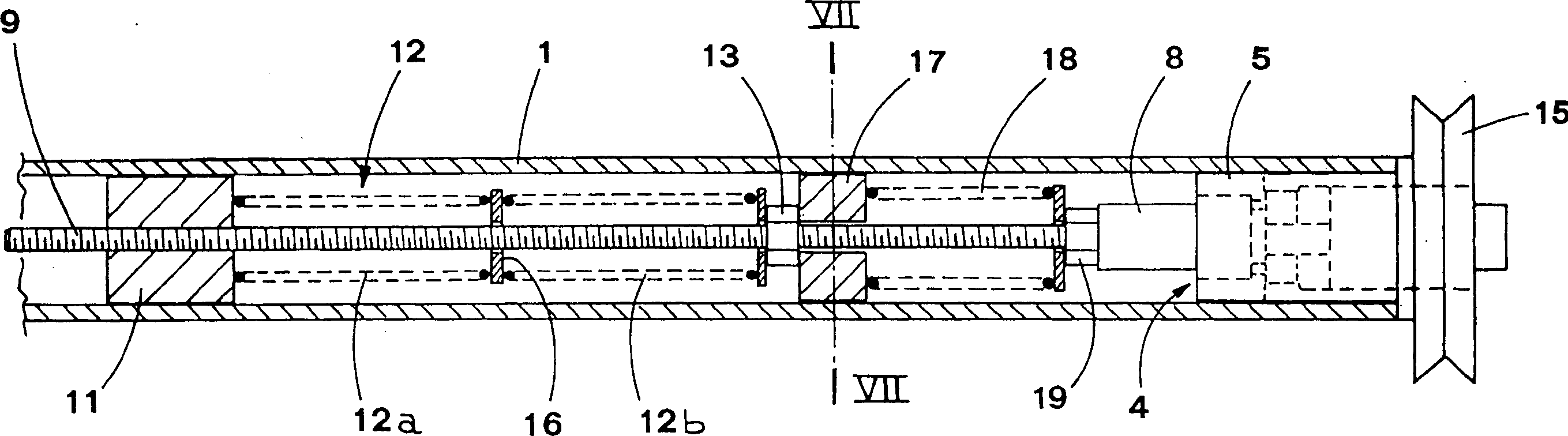

Electromagnetic catapult

InactiveCN104554815ASimple structureImprove performanceLaunching/towing gearElectric machineCatapult

The invention discloses an electromagnetic catapult. The electromagnetic catapult comprises a power mechanism, a guide rail mechanism, and a traction mechanism arranged on the guide rail mechanism; the power mechanism comprises a linear motor which is arranged in a motor bracket; the guide rail mechanism comprises an upper crossing roller shaft slide rail and a lower crossing roller shaft slide rail which are symmetrically arranged at the upper end and the lower end of the motor bracket; the traction mechanism comprises a traction bracket. The electromagnetic catapult has the beneficial effects of being simple in structure and stable in performance; meanwhile, the slide rail structure is arranged, so that the problem of excessively large frictional resistance during catapulting can be solved, and as a result, the use performance of the electromagnetic catapult is effectively improved; the electromagnetic catapult has a good market prospect.

Owner:亚欧益盟科技(北京)有限公司

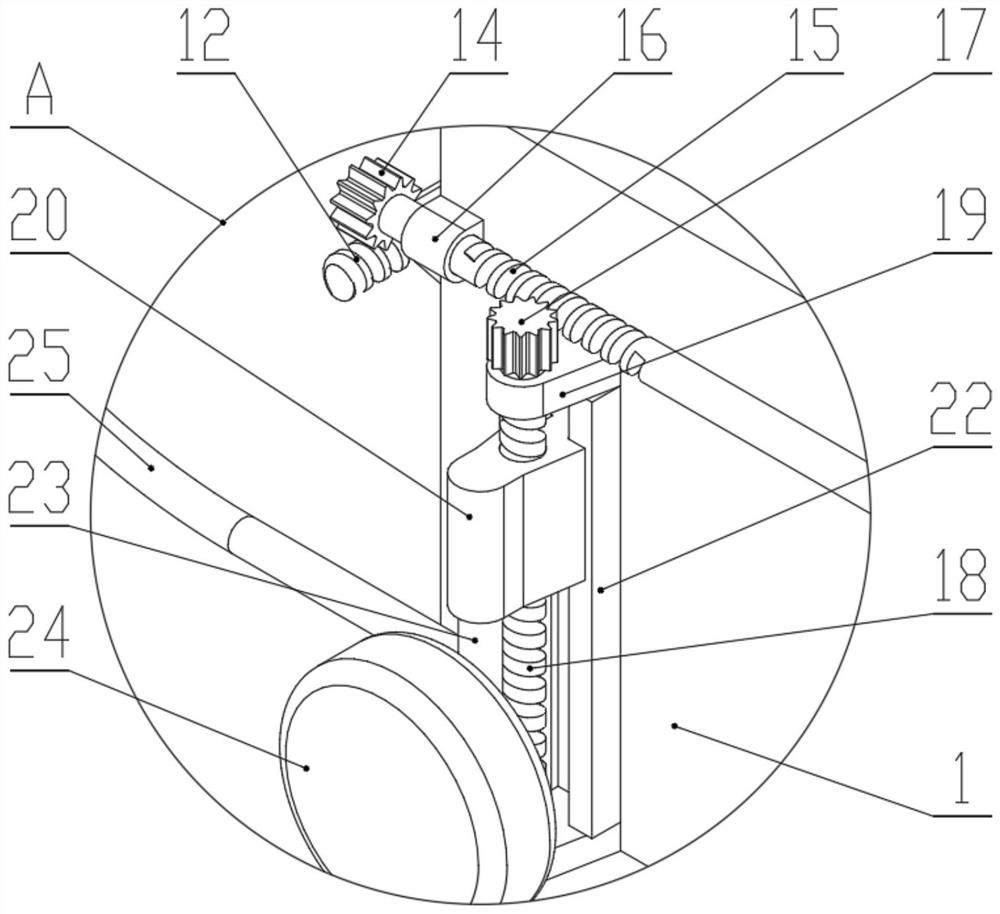

Roller carrier capable of automatically adapting to rolling shaft and automatically locking and application method of roller carrier

PendingCN113560918AAchieve supportSimple structurePositioning apparatusMetal-working holdersGear wheelControl engineering

Owner:宁苏辉

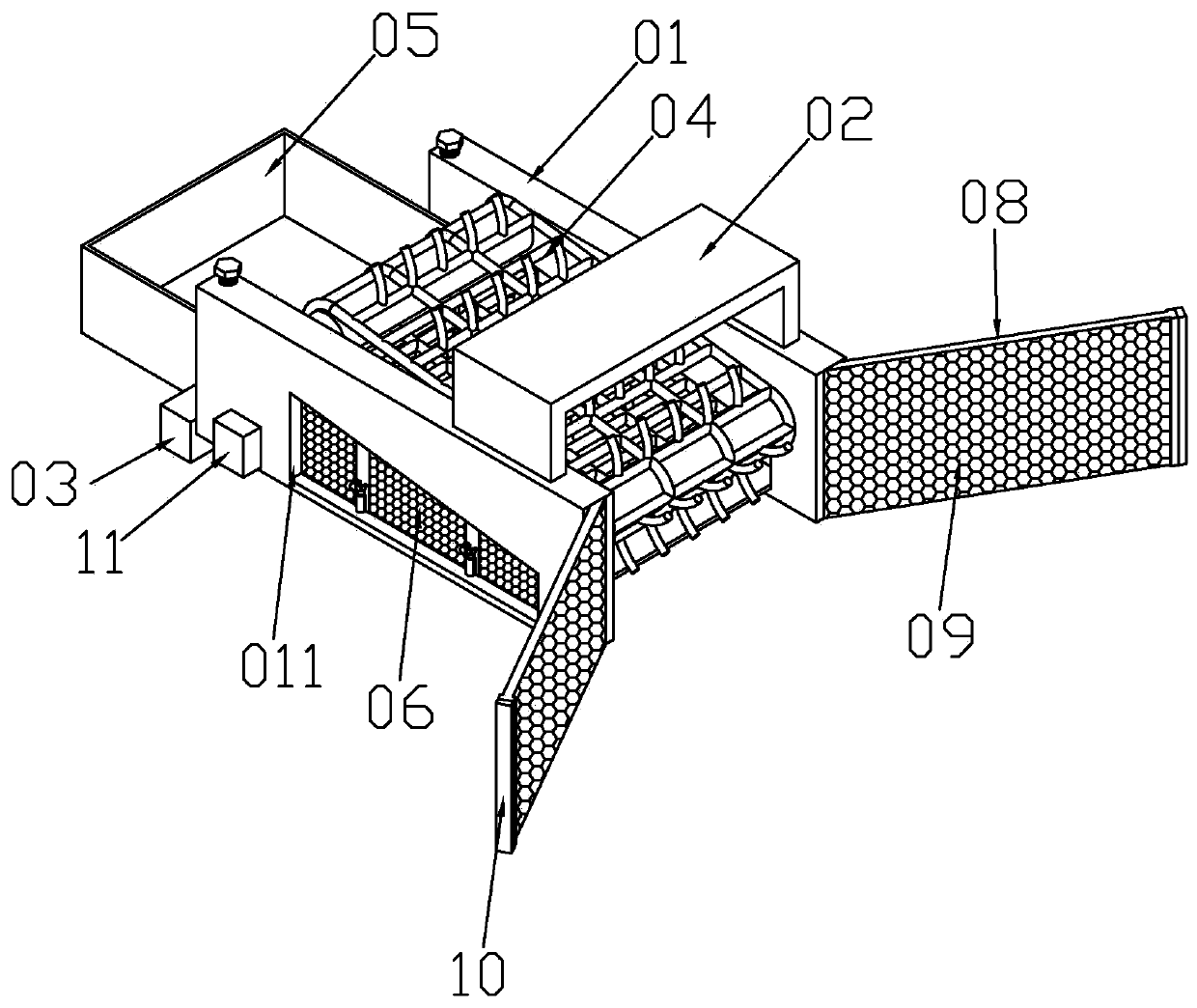

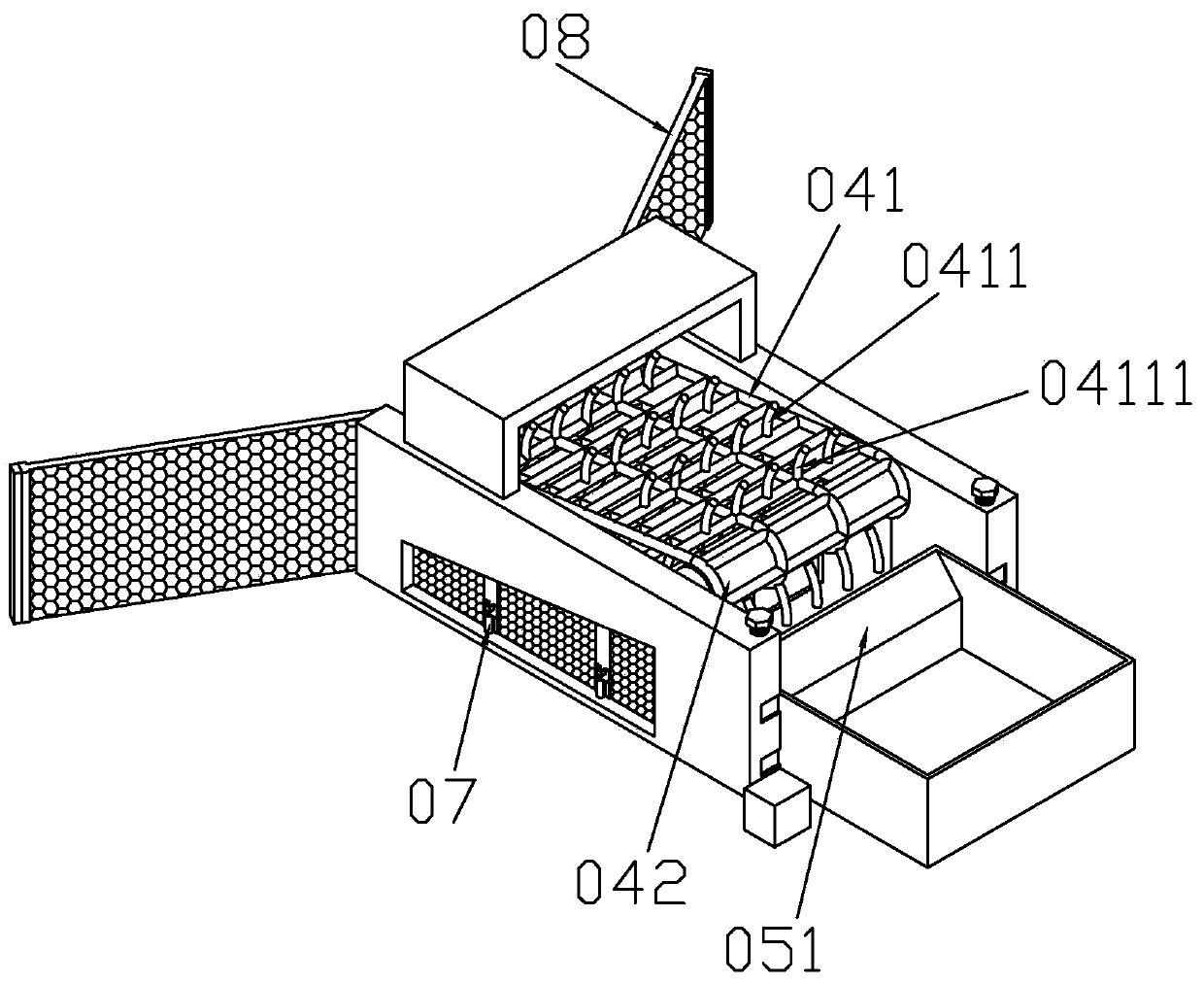

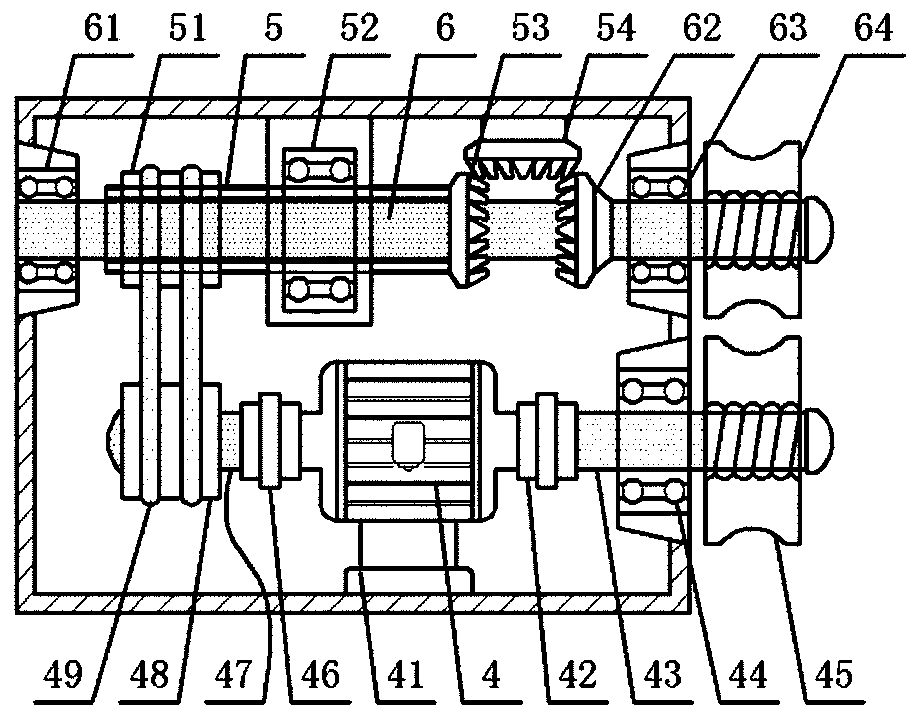

Intelligent carbon sliding plate bracket roll bending machine with supporting function and operation method thereof

ActiveCN111001685AImprove comfortImprove roll bending efficiencyShaping toolsPower current collectorsDrive shaftCoupling

The invention discloses an intelligent carbon sliding plate bracket roll bending machine with a supporting function, which comprises an upper bottom plate, a lower bottom plate and a rectangular box,wherein the rectangular box is arranged on the top surface of the upper bottom plate, supporting pieces are arranged between the upper bottom plate and the lower bottom plate, an air cylinder is mounted on the top surface of the lower bottom plate, and the top end of an air cylinder rod is fixedly connected with a rectangular plate on the bottom surface of the upper bottom plate through a fixing plate; a motor is arranged in the rectangular box; the left end of a motor shaft on the left end surface of the motor is in transmission connection with the left sides of two roller cylinders through atransmission mechanism; the right end of a motor shaft on the right end surface of the motor is movably connected with a main roller assembly through a first coupling; driven shafts penetrating through the roller cylinders are arranged in the roller cylinders, and steering mechanisms are arranged between the right sides of the roller cylinders and the corresponding driven shafts. The invention further discloses an operation method of the intelligent carbon sliding plate bracket roll bending machine with the supporting function. According to the invention, the problem that the height of the roll bending machine cannot be adjusted according to the height of a worker is effectively solved, the comfort of the worker is increased, and the roll bending efficiency is improved at the same time.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

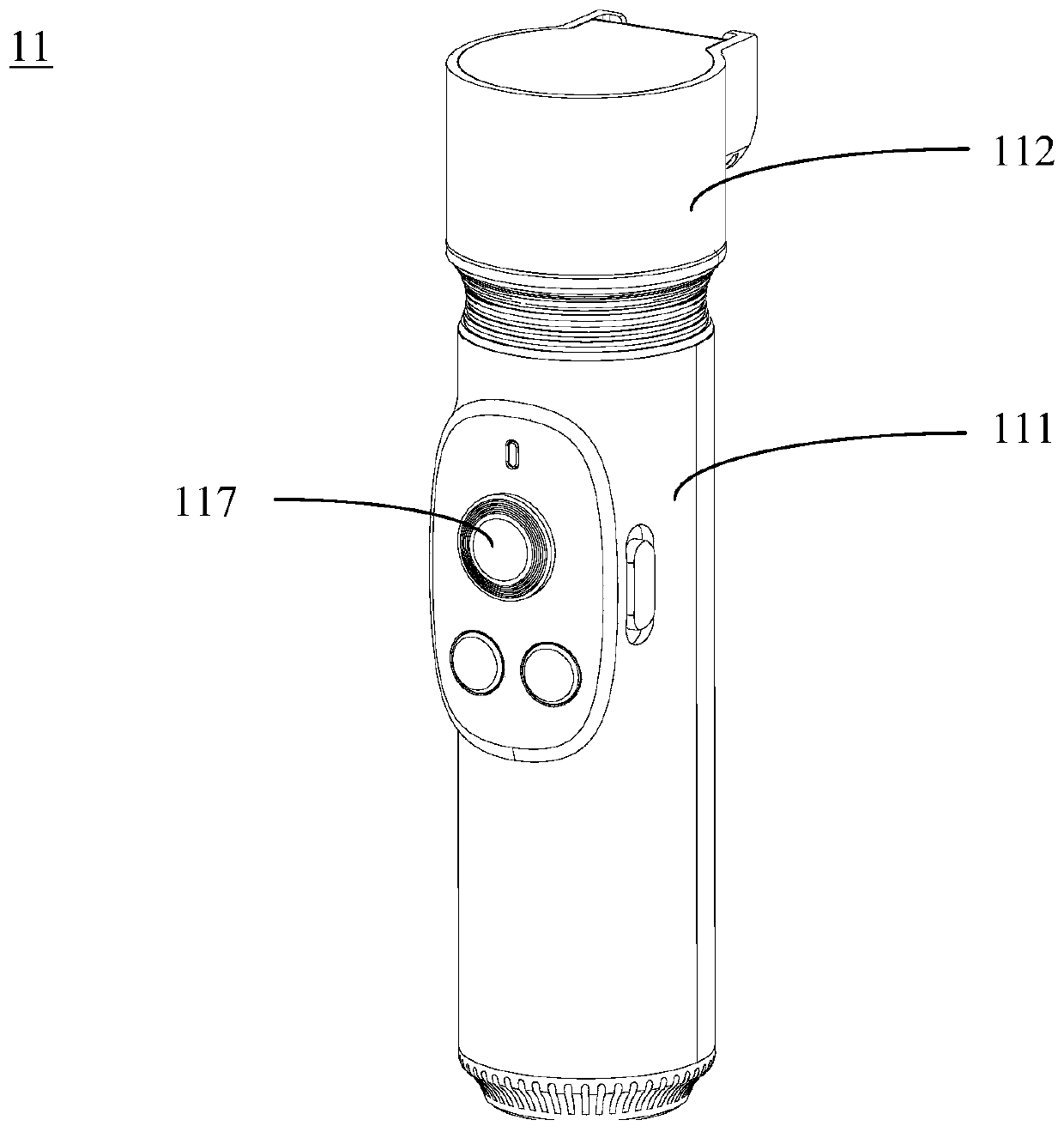

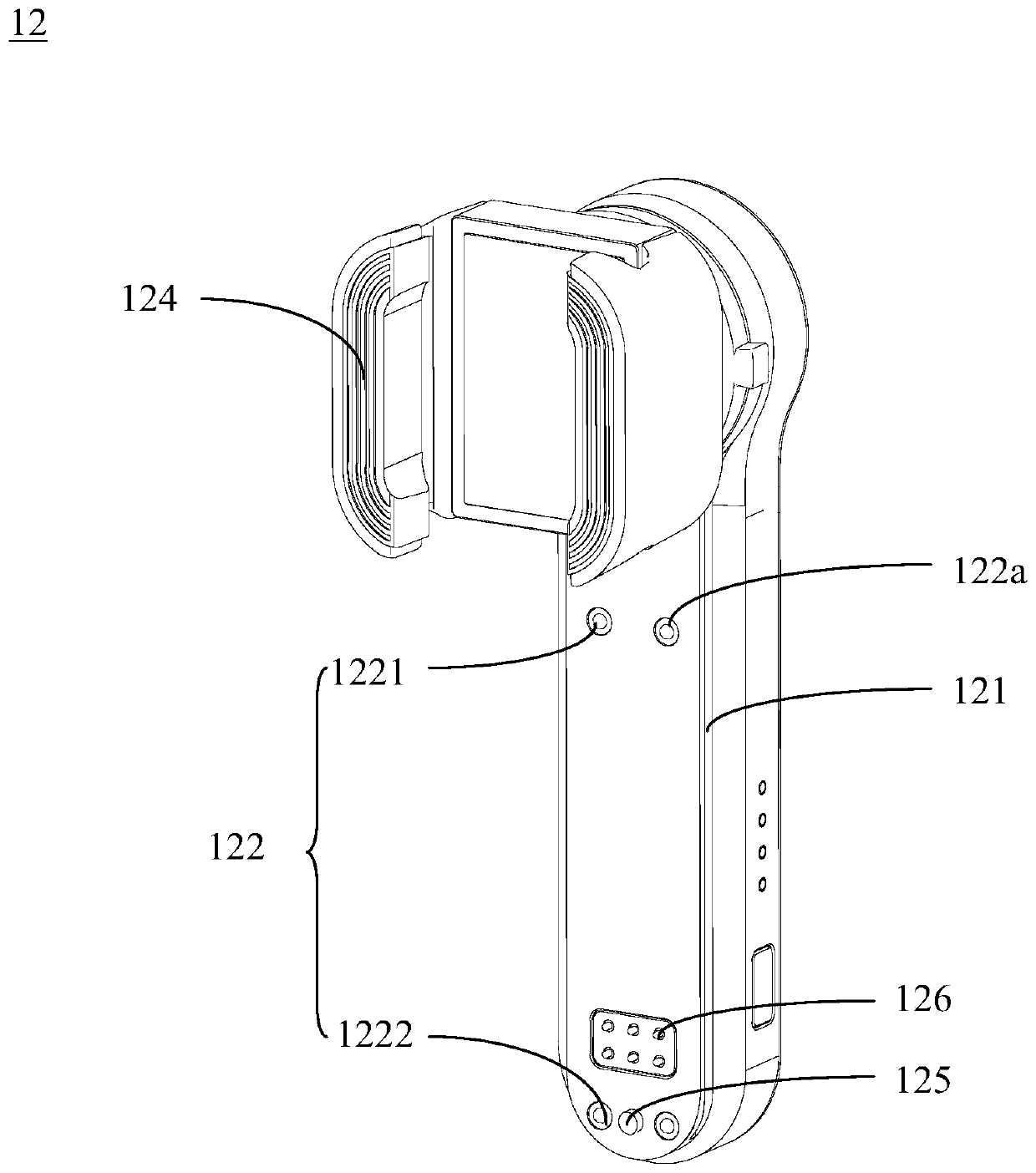

Stabilizer

ActiveCN111271554ASmall footprintImprove convenienceStands/trestlesCamera body detailsElectric machineryEngineering

The present invention relates to a stabilizer configured to rotate about a heading axis and a transverse roller for stabilizing a photographing device. The stabilizer comprises a handle with a headingaxis motor, and a connecting arm, wherein a first connecting piece is arranged on the side surface of the handle; a clamping piece driven by a transverse roller motor is arranged on the far end partof the connecting arm, and a second connecting piece matched and connected with the first connecting piece is arranged on the side surface of the connecting arm, so that the connecting arm is able tomove in a far side direction or a near side direction relative to the handle and is able to move to a storage state with reduced occupied space.

Owner:GUILIN ZHISHEN INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com