Automatic cleaning ship

An automatic, hull-based technology, applied to motor vehicles, special-purpose vessels, non-electric variable control, etc., can solve problems such as low efficiency, small lake area, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] When the following terms such as "upper" and "lower", "right" and "left" or similar relative expressions are used in this embodiment, these only refer to the drawings and not necessarily the actual usage.

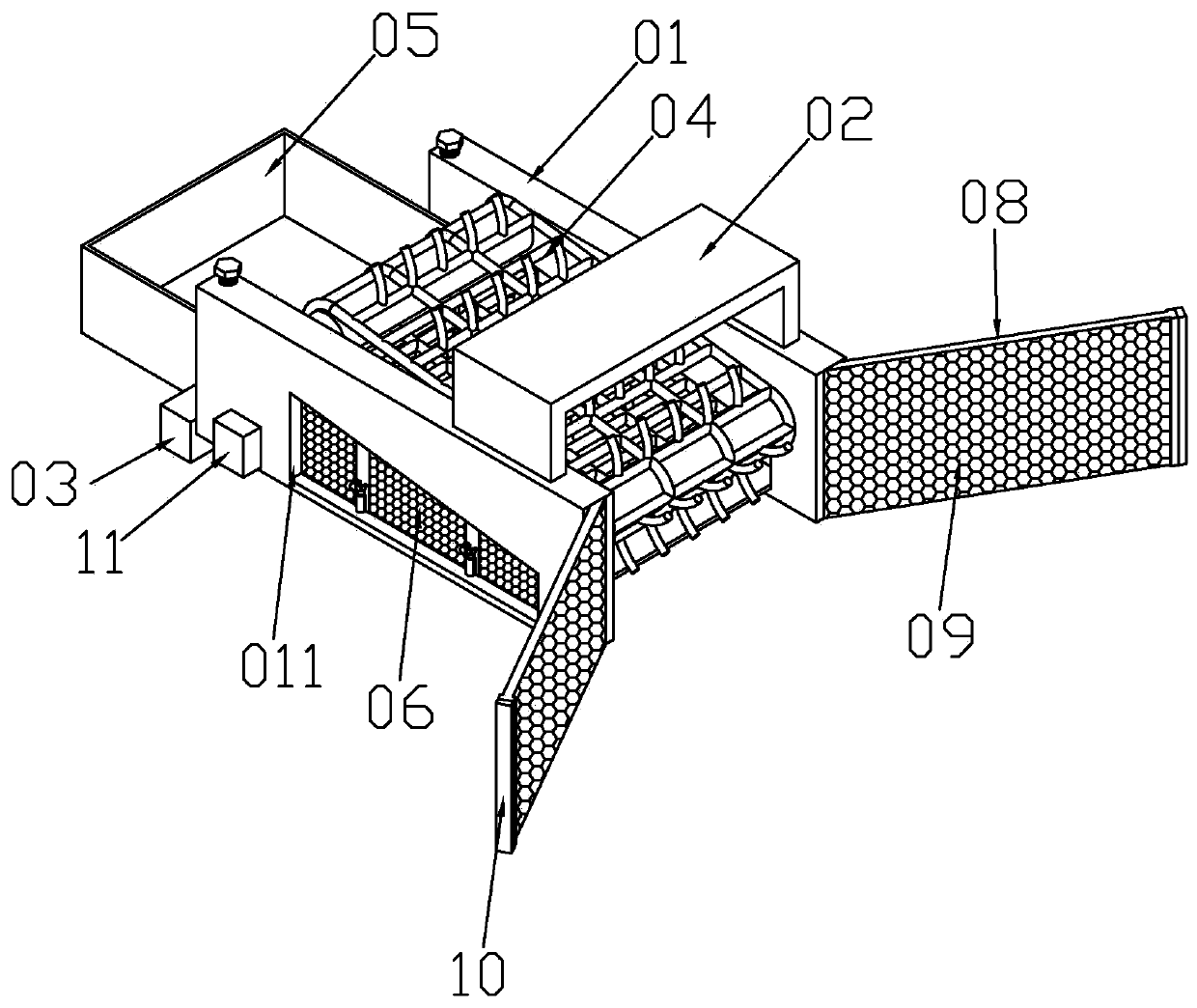

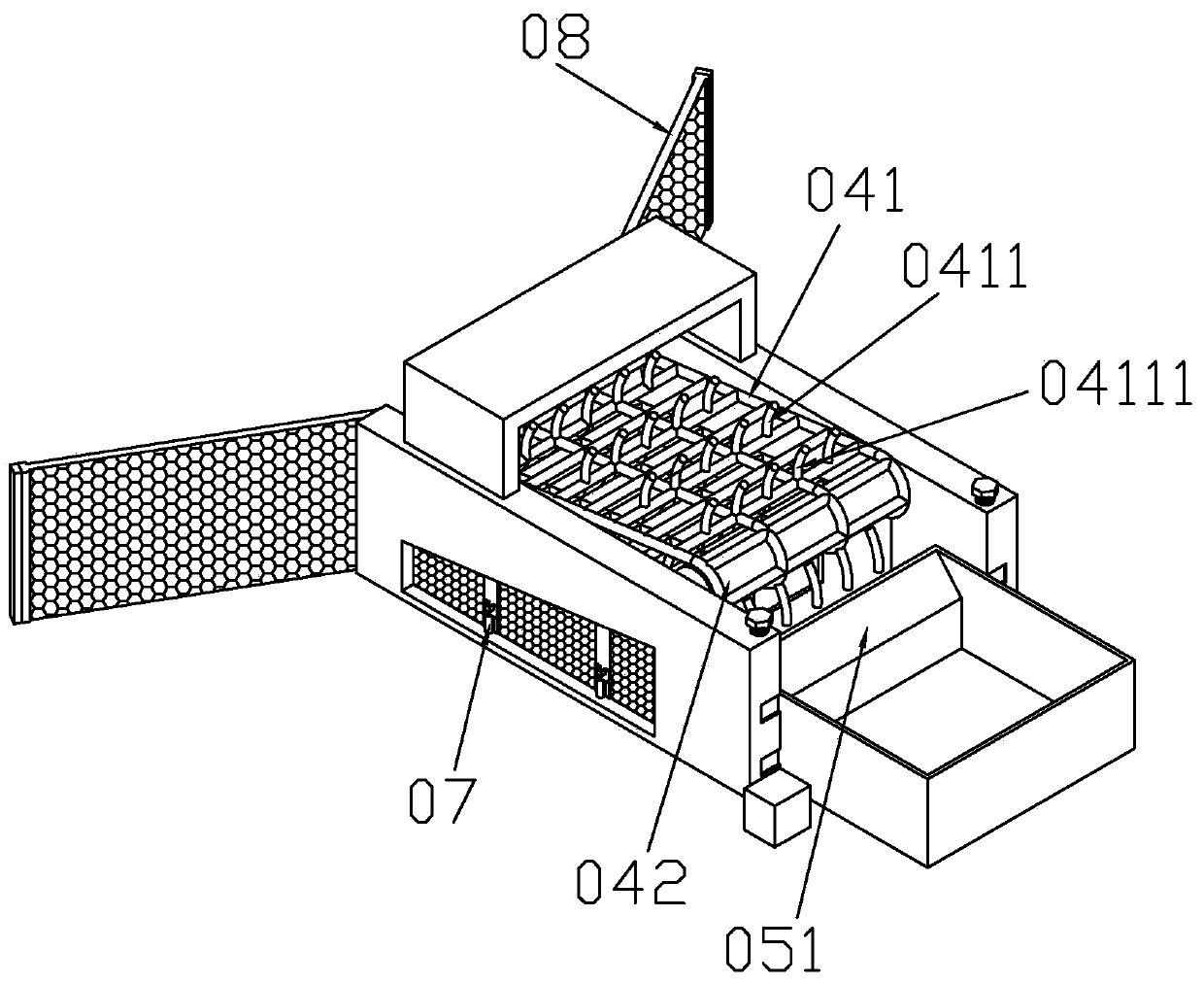

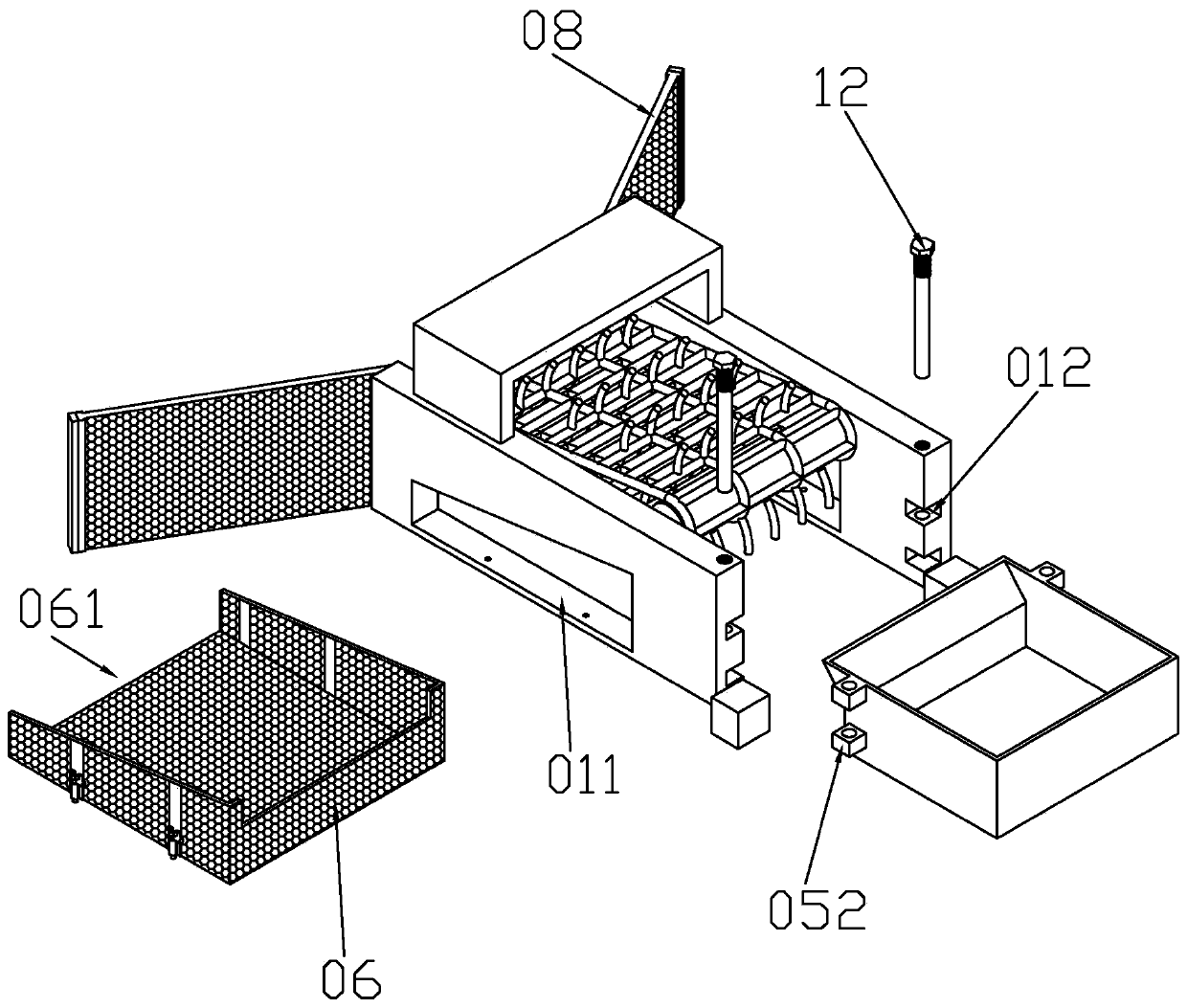

[0033] Specific embodiments of the present invention such as Figure 1-6As shown, an automatic cleaning ship includes a hull, and the hull includes two sub-hulls 01 with opposite sides. In this embodiment, the hull includes a control room 02, and the control device is arranged in the control room 02. The tails of the two sub-hulls 01 are all provided with There is a propeller 03, and the propeller 03 is electrically connected with the control device. The transmission device 04 and the storage frame 05 are arranged between the two sub-hulls 01 from front to back. Block 052, the sub-hull 01 is provided with a groove 012 for insertion of the plug-in block 052, and the plug-in block 052 and the groove 012 are provided with a fixed rod 12, and the fixed rod 12 is threaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com