Intelligent carbon sliding plate bracket roll bending machine with supporting function and operation method thereof

A carbon skateboard and bracket rolling technology, which is applied in the field of intelligent carbon skateboard bracket roll bending machines, can solve the problems of low bending efficiency, height adjustment of roll bending machines, and high labor intensity of workers, so as to increase comfort and improve bending efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

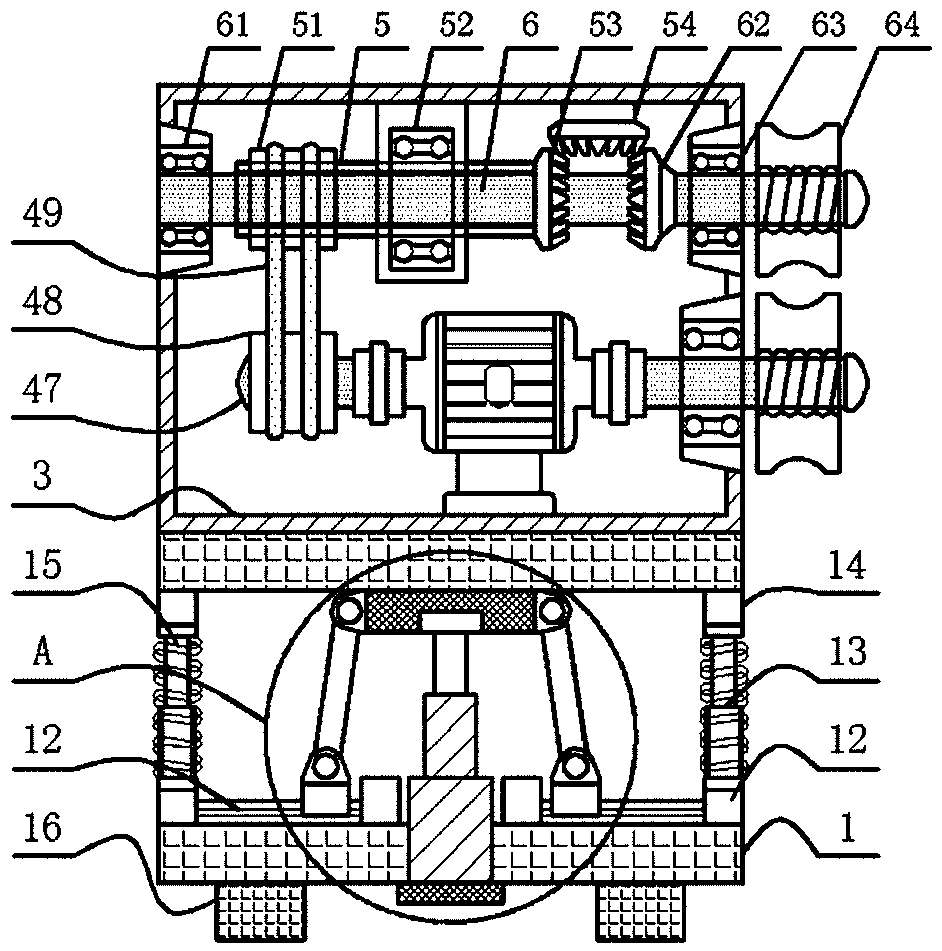

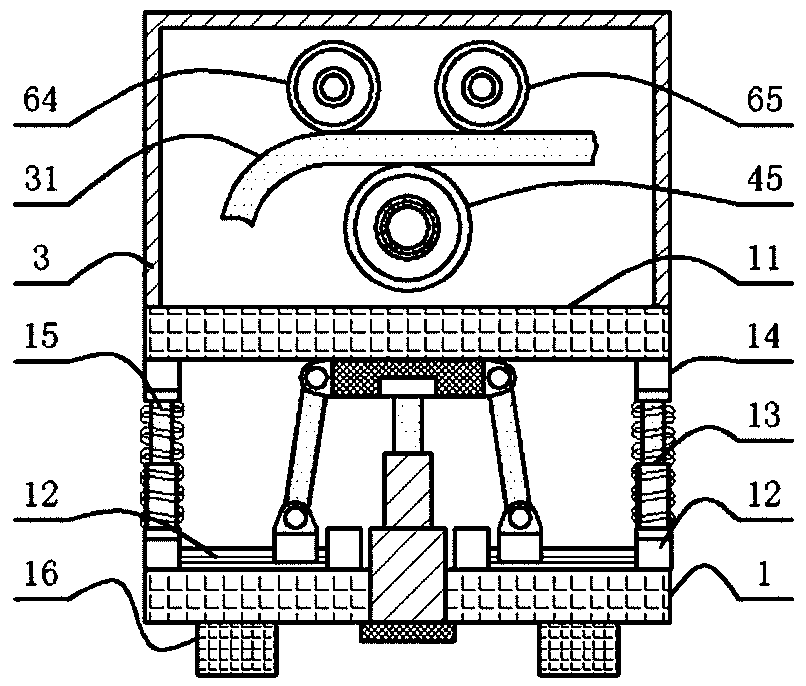

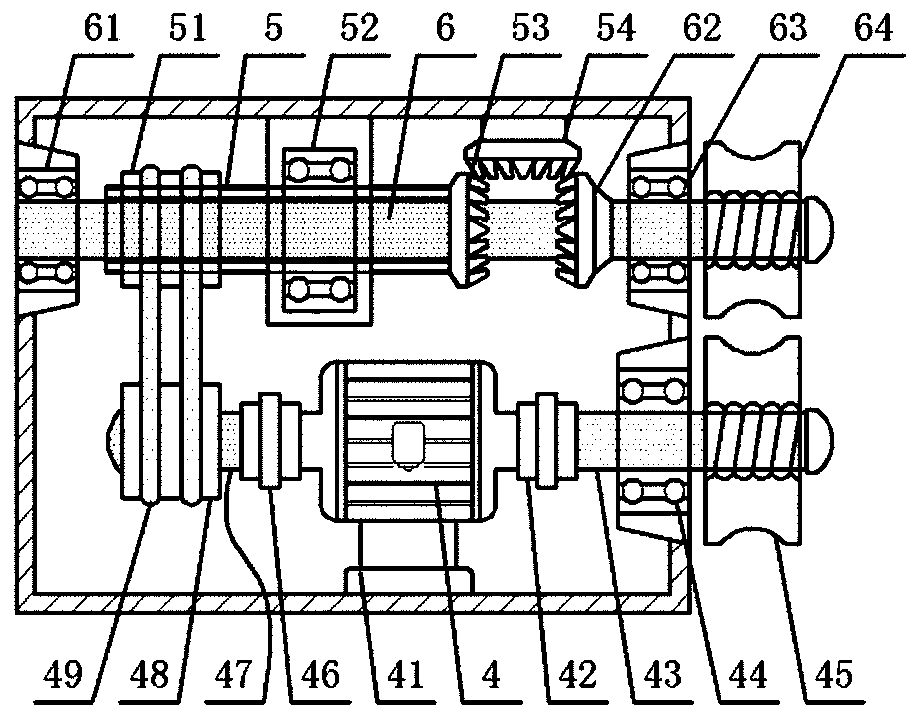

[0039] Embodiment 1: see Figure 1-5 , an intelligent carbon skateboard bracket roll bending machine with supporting functions, including an upper base plate 11, a lower base plate 1, and a rectangular box 3, the upper base plate 11 and the lower base plate 1 are rectangular plates, and the upper base plate 11 is located parallel to the lower base plate 1, a rectangular box 3 is arranged on the top surface of the upper bottom plate 11, support members are provided between the four corners of the bottom surface of the upper bottom plate 11 and the four corners of the top surface of the lower bottom plate 1, and the upper bottom plate 11. A rectangular plate 17 is arranged at the center of the bottom surface. The bottom surface of the rectangular plate 17 is recessed with a fixing groove, and a fixing plate is installed in the fixing groove. The top surface of the lower bottom plate 1 is recessed with a cylinder hole, and a cylinder hole is installed in the cylinder hole. 2. The...

Embodiment 2

[0050] Example 2: see Figure 6 , in this embodiment, the present invention also proposes an operation method of an intelligent carbon skateboard bracket bending machine with a supporting function, including the following steps:

[0051] Step 1, the cylinder 2 communicates with the external air source through the air pipe, and the motor 4 is electrically connected with the external power supply through the wire; the lifting of the cylinder rod of the cylinder 2 is controlled, and the rectangular box 3 is adjusted to a suitable height;

[0052] Step 2, the cylinder rod of the cylinder 2 is raised and lowered, the fixed plate at the top of the cylinder rod lifts up the rectangular plate 17, and the second hinge seat on the left and right ends of the rectangular plate 17 drives the first hinge seat and the slider 23 through the hinge rod 24, and the slider 23 Sliding back and forth along the slide rail 22;

[0053] At the same time, the telescopic rod 13 between the four corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com