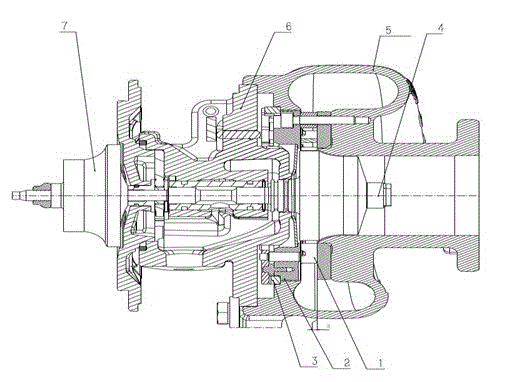

Adjustable nozzle for turbosupercharger

An adjustable nozzle technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems affecting the engine's response ability and lag, and achieve the effect of simple structure and technical improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

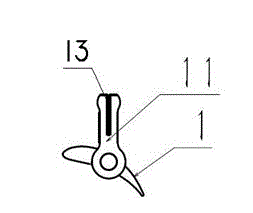

[0023] Such as image 3 As shown, the elastic driven rocker arm 11 is a pivot arm with a longitudinal slot in the middle of the upper section, and the upper section of the pivot arm has a longitudinal slot 13 that runs through to the upper end of the pivot arm. The longitudinal slot 13 makes the upper end of the rotating arm have a certain possibility of elastic loading, so that the upper end of the rotating arm can be compressed and clamped in the groove of the driving disc.

Embodiment 2

[0025] Such as Figure 4 As shown, the elastic driven rocker arm 11 is composed of two symmetrical single arms 12, and the two single arms 12 are fixed as one body with a longitudinal gap.

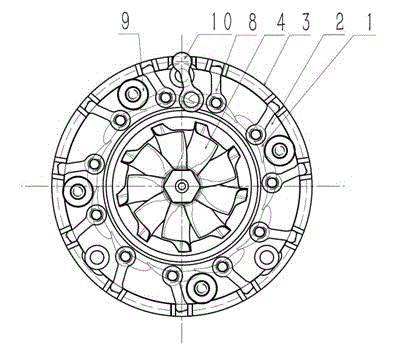

[0026] Since the present invention provides a mechanical part that can be elastically loaded, that is, the elastic driven rocker arm 11, which replaces the rigid driven rocker arm, can be elastically compressed and assembled in the groove of the drive disc 3, and always keep in contact with the drive disc 3, so It can effectively remove the hysteresis of the rotational movement of the guide vanes. As long as the driving demand of the engine is transmitted to the drive disc 3 through the actuator, the drive disc 3 will immediately drive the elastic driven rocker arm 11 to rotate clockwise or counterclockwise to realize the guide The adjustable nozzle formed by the rotation of the flow vane enables the turbine to obtain the required flow change immediately, and fully improves the response ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com