Large-diameter steel strip winding pipe die and winding method thereof

A large-diameter, steel-belt technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as the inability to use tapered pipe production, affecting production efficiency and product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0154]为了使本发明的目的、技术方案及优点更加清楚明白,以下结合实施例,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅仅用以解释本发明,并不用于限定本发明。

[0155]下面结合附图1至2及具体实施例对本发明的应用原理作进一步描述。

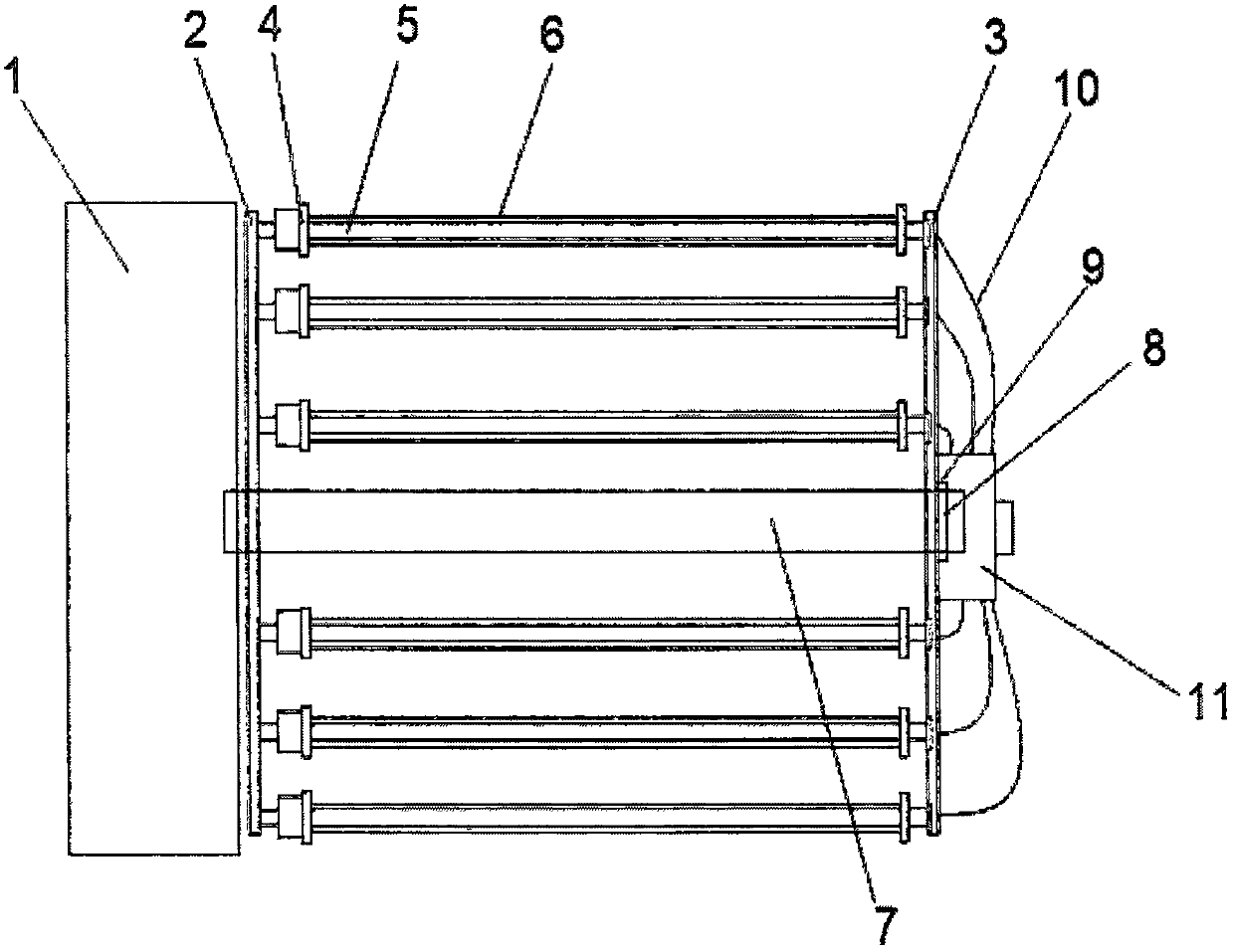

[0156]本发明实施例提供的大口径钢带缠绕管模具包括:机组主轴1、第一支撑圆盘2、第二支撑圆盘3、档盘4、滚轴5、滚筒6、芯轴7、销孔8、销轴9、液压管10、液压泵11;

[0157]第一支撑圆盘2设置在机组主轴1上,第一支撑圆盘2上设置有若干档盘4,档盘4上安装有滚筒6,滚筒6内安装有滚轴5;滚筒6的末端安装在第二支撑圆盘3上,滚筒6的两端分别与设置在滚轴5上的两个档盘4相连接;芯轴7贯穿设置在第一支撑圆盘2与第二支撑圆盘3中部,芯轴7穿过第二支撑圆盘3外的一端设有销孔8,销轴9插在销孔8内;

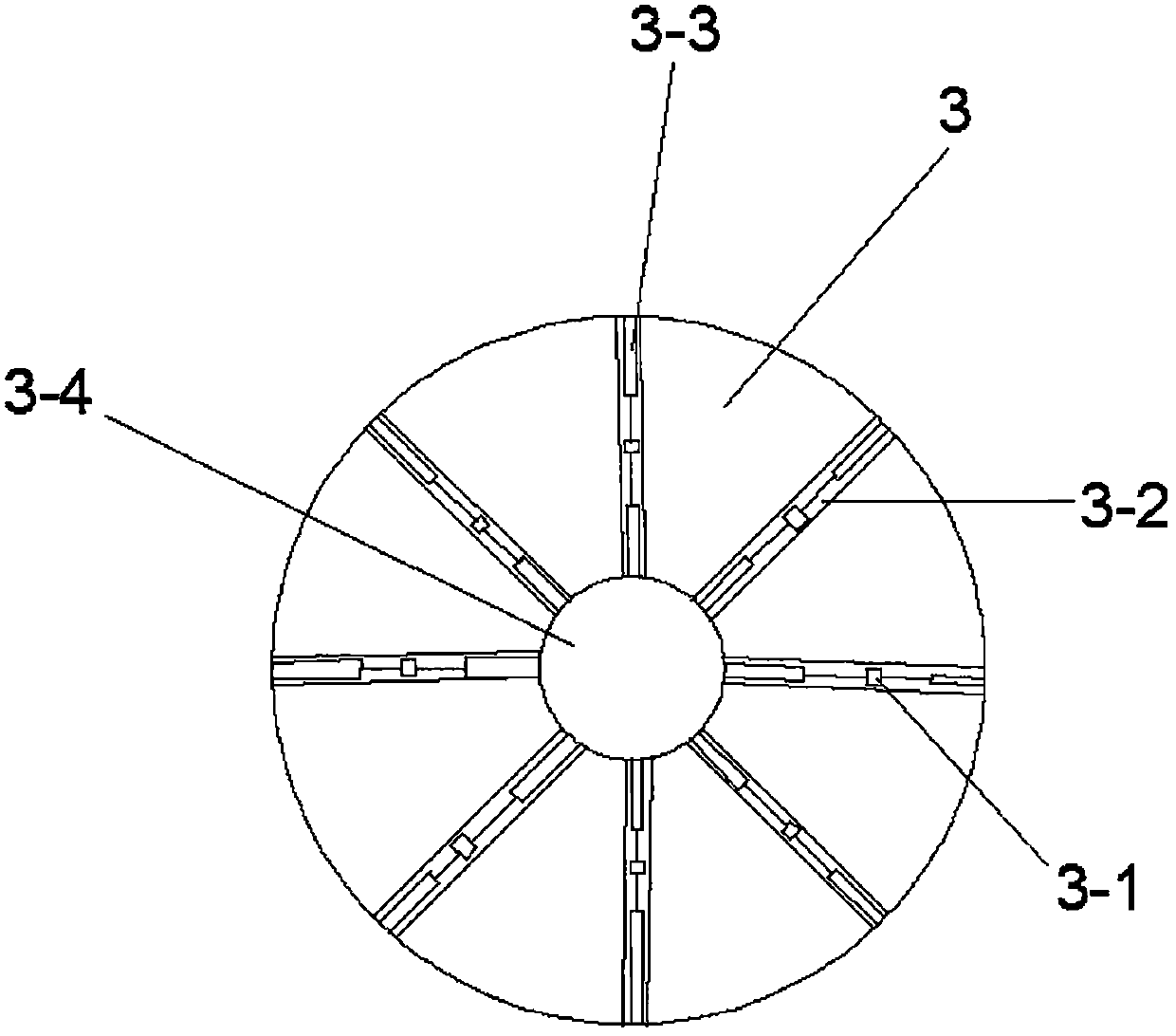

[0158]第二支撑圆盘3上设有圆盘内孔3-4和固定槽3-2,固定槽3-2的前端与第二支撑圆盘的内径连接,固定槽3-2的后端与圆盘内孔3-4的外径连接;固定槽3-2内设有液压杆3-3,液压杆3-3的前端与第二支撑圆盘3的内径连接,液压杆3-3的后端与圆盘内孔3-4的外径连接,液压杆3-3的中部设有锁紧槽3-1;第二支撑圆盘3的外端中心处安装有液压泵11,液压泵11的输出端与液压管10的输入端连接,液压管10的输出端与液压杆3-3的输入端连接。

[0159]所述的滚轴5环绕芯轴7设置;所述的滚筒6组成的包络面的直径大于第一支撑圆盘2和第二支撑圆盘3的外径;所述的锁紧槽3-1的宽度与滚轴5的轴径相等,锁紧槽3-1的长边所在方向与第二支撑圆盘3的径向方向平行;所述的第一支撑圆盘2、第二支撑圆盘3和滚筒6的外轮廓呈直筒状。

[0160]所述的滚筒6两端设有用于调节滚筒6位置的档盘4,所述档盘4套装在滚轴5上,所述档盘4与滚轴5螺纹配合,所述的滚筒6与滚轴5间隙配合,所述的滚筒6两端设有用于使得各滚筒6同步转动的传动链,所述滚筒6两端的外圆表面上设有用于安装该传动链的环形凹槽,传动链的外缘轮廓位于滚筒6组成的包络面内。

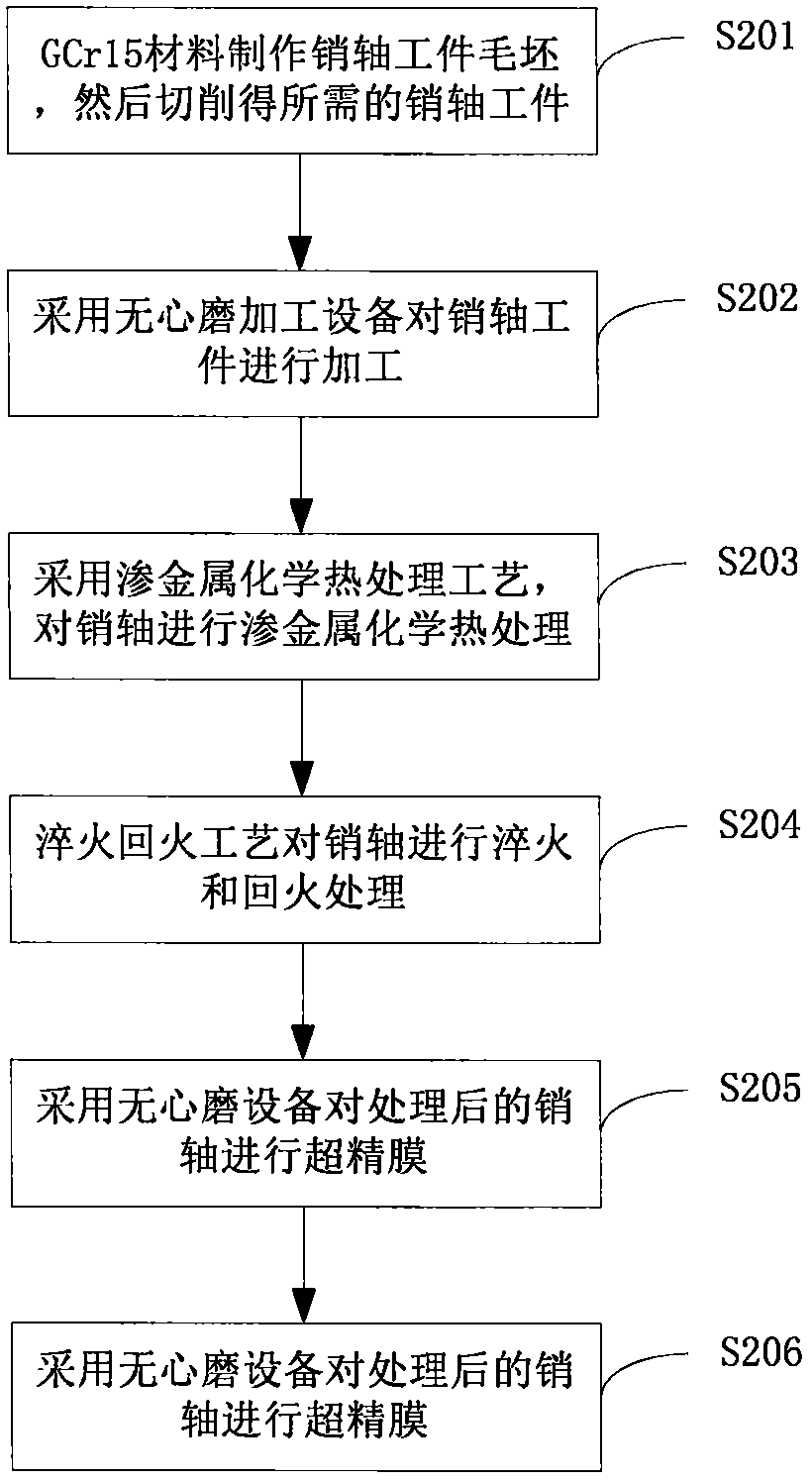

[0161]如图3所示:本发明实施例提供的机组主轴1的加工方法包括以下步骤:

[0162]S101、选料:选取无缝钢管原料,从原料上切割下符合长度的管段;

[0163]S102、端部加热:将上述管段的一端加热至1050-1100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com