Steering and braking in-line skate or roller ski

a technology of inline skates and roller skis, applied in the direction of skateboards, skis, sport apparatus, etc., can solve the problems of not steering, limiting the overall performance of skates in terms of speed, handling, range of terrain,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

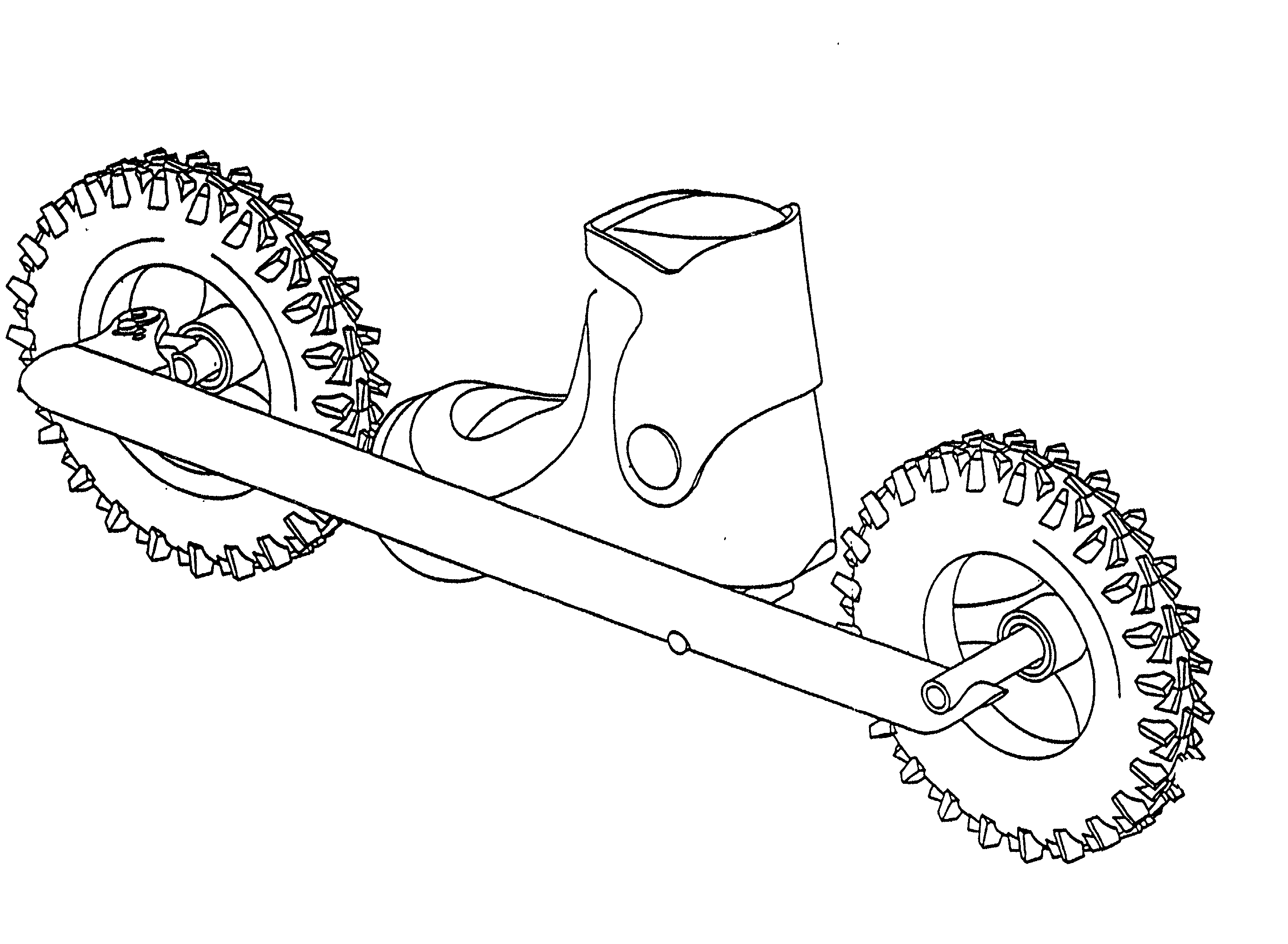

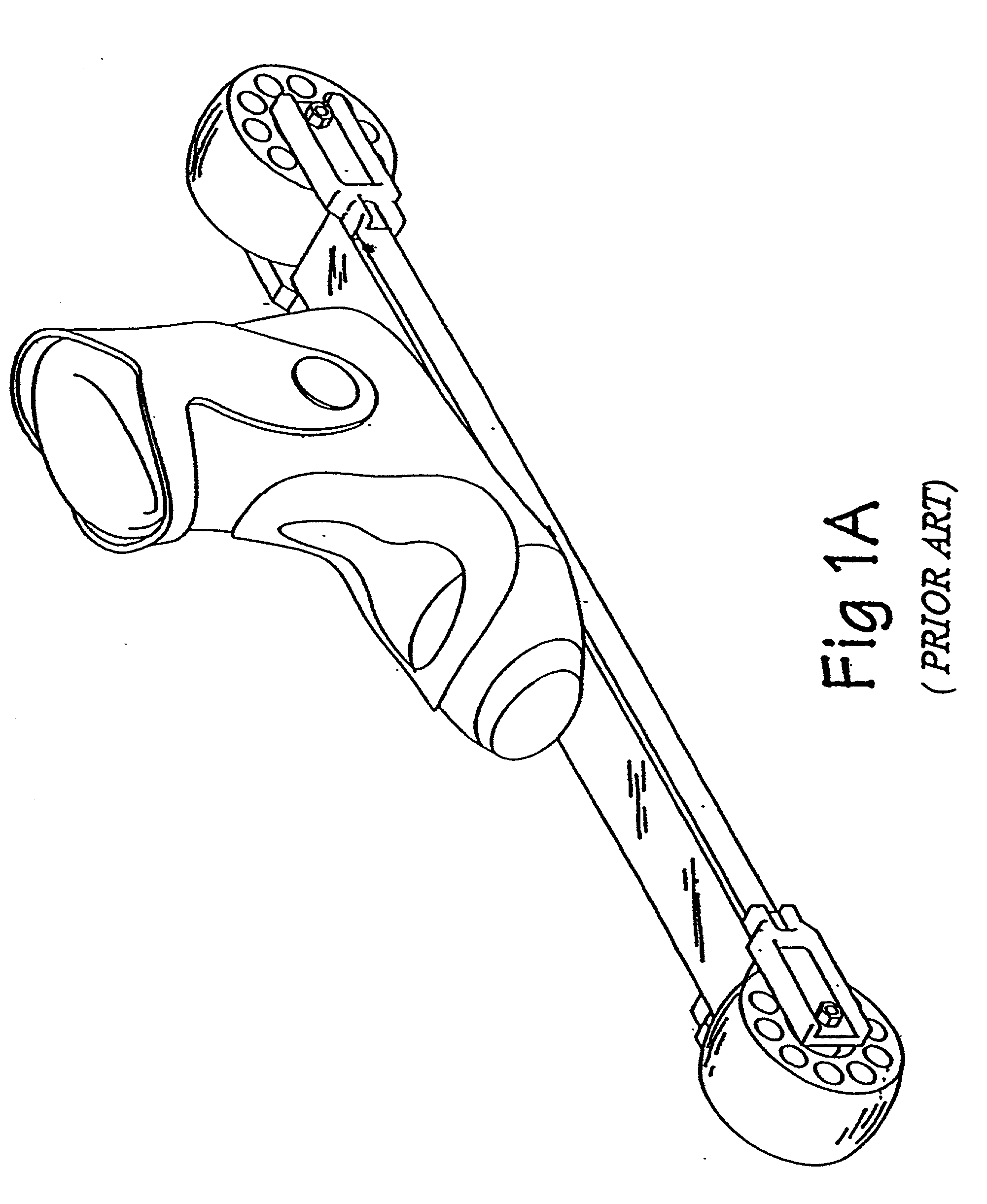

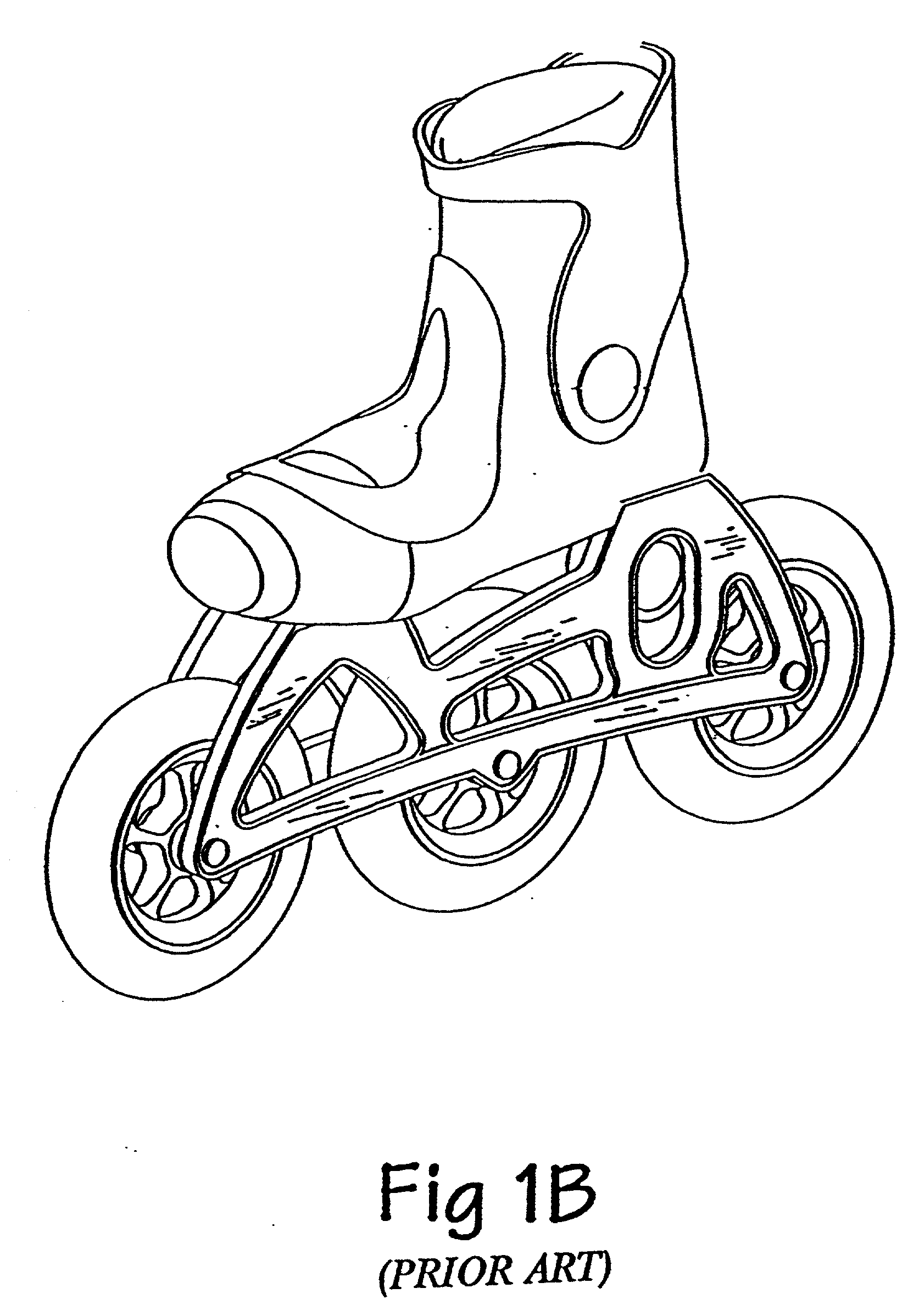

[0051] The invention will be discussed following a brief review of relevant features of certain prior art wheeled sports devices. In illustrating embodiments of the invention, certain preferred as well as several necessary mechanical components will be shown, for which common mechanical or automotive terminology is employed, with corresponding elements in different embodiments bearing the same numeral, but possibly an alphabetic suffix a.b . . . to distinguish among them. Among the elements appearing in the figures are a tire 10, wheel 11, damper sealing boot 12, wheel bearing assembly 13, wheel support assembly 14, kingpin 15, steering pivot assembly 16, damper housing 17, centering force mechanism 18, damper piston 19, steering link 20, chassis 21, steering axis 22, tire patch 23, fluid chamber 24, connecting pin 25, steering stop pin 26, steering lockout hole 27, steering limit track 28, suspension pivot 29, suspension link 30, and wheel rotation axis 31.

[0052] A survey of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com