Method for operating motor vehicle brake system with anti-lock braking system and device for carrying out method

An anti-lock braking system, a technology for motor vehicles, applied in the direction of brakes, etc., can solve the problems of high braking pressure, increased NVH value roughness, etc., and achieve the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

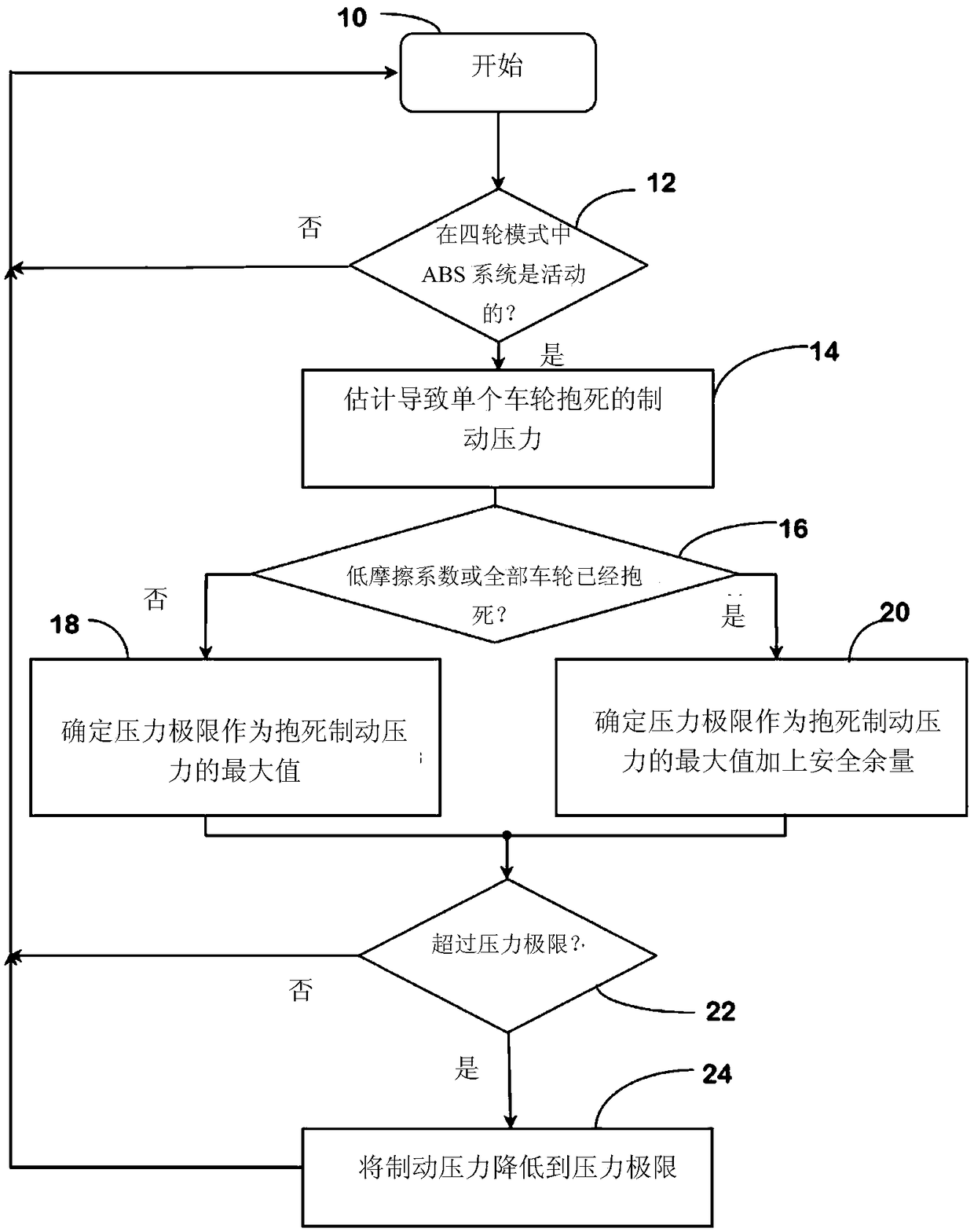

[0030] This method is usually implemented as a background loop in the case of microprocessor-based brake controllers. Individual steps of the method can—if technically meaningful—thus be omitted, replaced by other steps or their sequence changed.

[0031] After the start 10 of the method, in a step 12 it is queried whether the braking system is in ABS mode for all four wheels. If not, the process waits until the condition exists. Of course, the program can also be implemented as part of the corresponding four-wheel ABS control program and can be called up in the same way; query 12 would then be superfluous.

[0032] Alternatively, it is conceivable to use the invention in other states where a limitation of the brake pressure is foreseen, for example in certain ESP states.

[0033] If a four-wheel ABS mode is present, then in step 14 the brake pressures that will cause the wheels of each of the four wheels to lock are estimated. For this purpose, in the case of ABS control, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com