Phase change energy storage cooling device of disc brake

A disc brake, phase-change energy storage technology, applied in the components of the brake, brake type, heat storage equipment, etc., can solve the problem of limited heat dissipation, achieve the effect of reducing temperature, easy installation, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

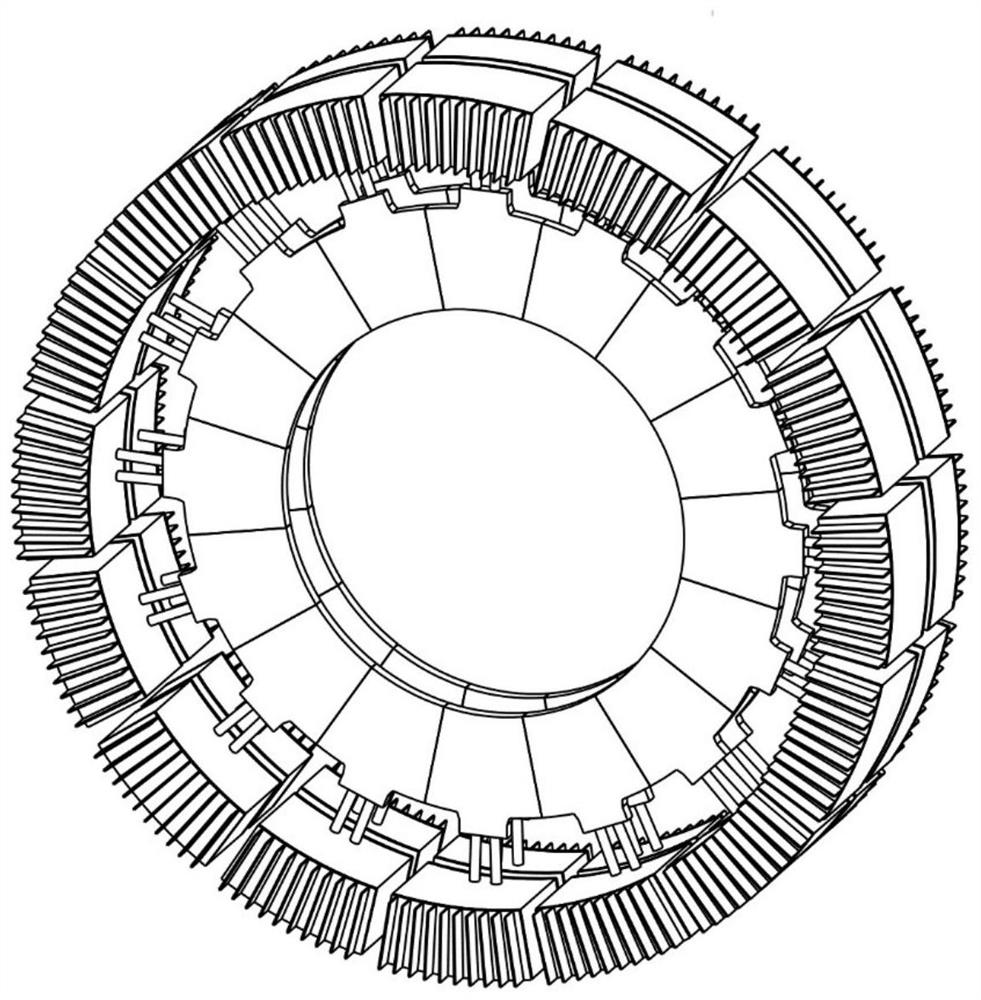

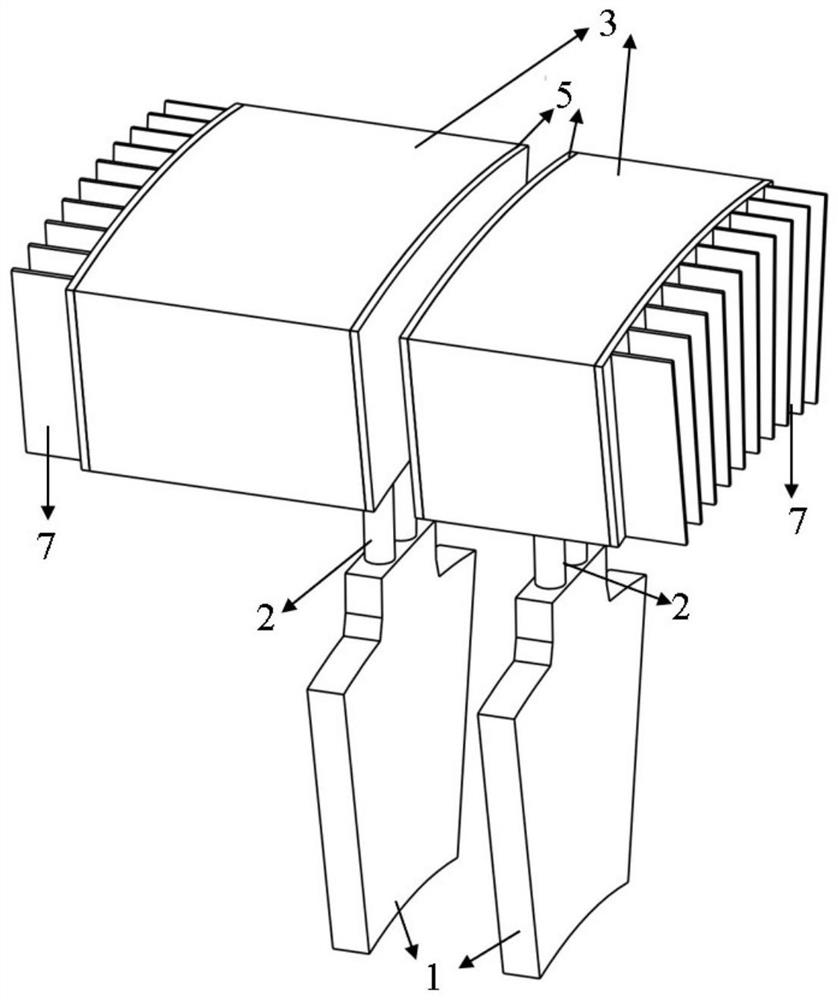

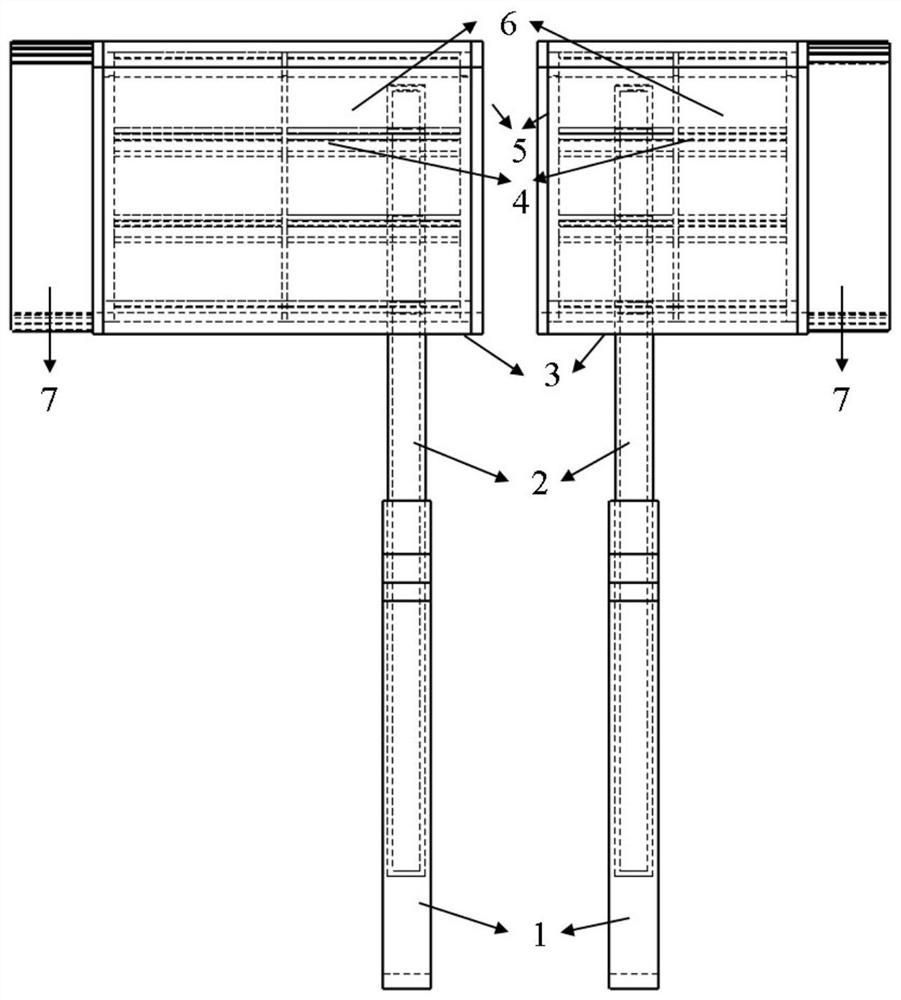

[0042] see figure 2 , 3 It is a structural schematic diagram of a group of heat-absorbing modules of a phase-change energy-storage cooling device for a disc brake. The phase-change energy-storage cooling device of the present invention is composed of sixteen groups of heat-absorbing modules. Each group of heat-absorbing modules includes a group of mercury heat pipe heat transfer modules and a group of Pb-based alloy phase change material energy storage modules, in which the heat pipe heat transfer module consists of 4 image 3 The middle heat pipe 2 is composed, and the phase change material energy storage module is composed of two device shells and the phase change material therein. The embodiment of the present invention includes: the static disc core plate 1 is a part of the disc brake, the heat pipe 2 transfers the heat from the static disc core plate 1 to the Pb-based alloy phase change material 6, and the Pb-based alloy phase change material 6 is spread on the phase ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com