Electronic device housing and preparation method for the same

A technology for electronic equipment and shells, applied in the field of electronic equipment shells and their preparation, can solve the problems of inability to transfer and absorb heat, poor temperature consistency, low heat dissipation efficiency, etc., achieve high latent heat, good consistency, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] In the second aspect, this implementation mode also provides a method for manufacturing the casing of the above-mentioned electronic device, the method includes the following steps:

[0101] (a) Weigh capric acid and lauric acid respectively, mix and heat, and stir continuously during the heating process until all capric acid and lauric acid are heated to a molten state to obtain the capric acid-lauric acid binary composite phase variable material;

[0102] (b) Place the shell body in a water bath at 38°C to 45°C, inject the capric acid-lauric acid binary composite phase change material into the hollow cavity, and after the injection is completed, put the shell body take out;

[0103] (c) Paste the heat conduction sheet on the inner layer of the housing body, and then attach the heat dissipation sheet to the heat conduction sheet.

[0104] The method for preparing the casing of an electronic device provided in this embodiment is to firstly heat capric acid and lauric ...

Embodiment 1

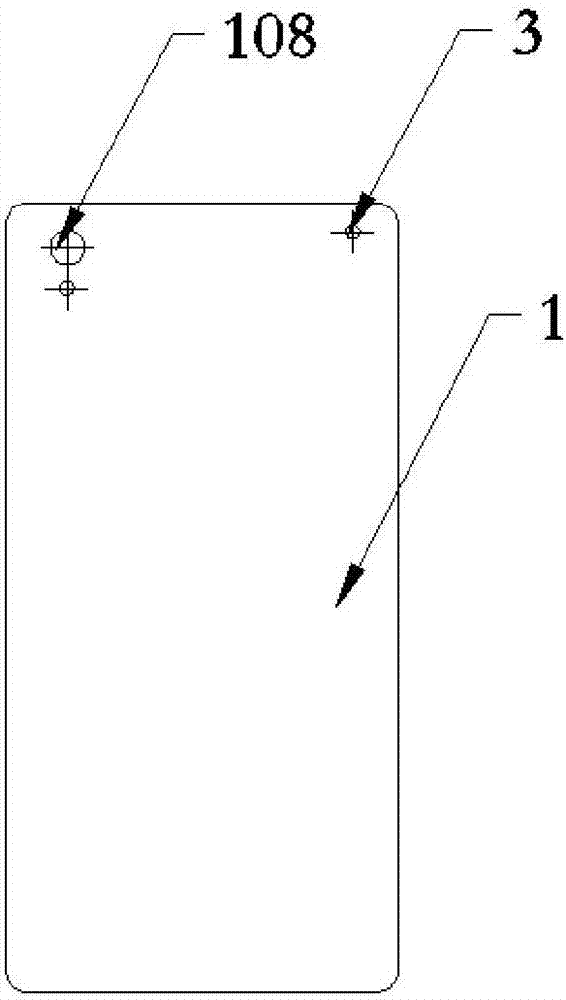

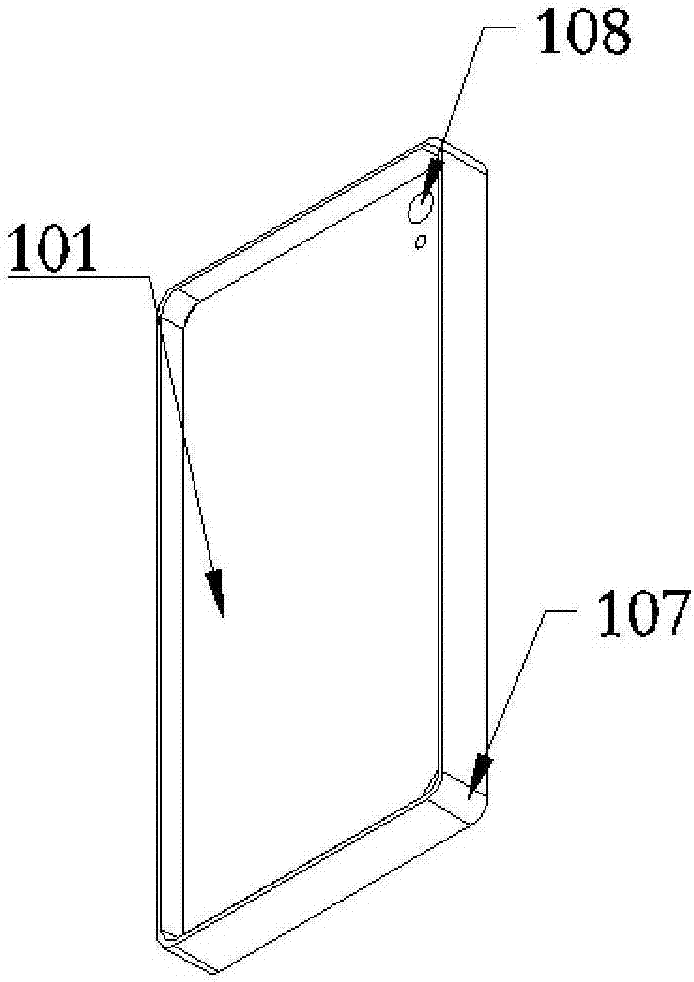

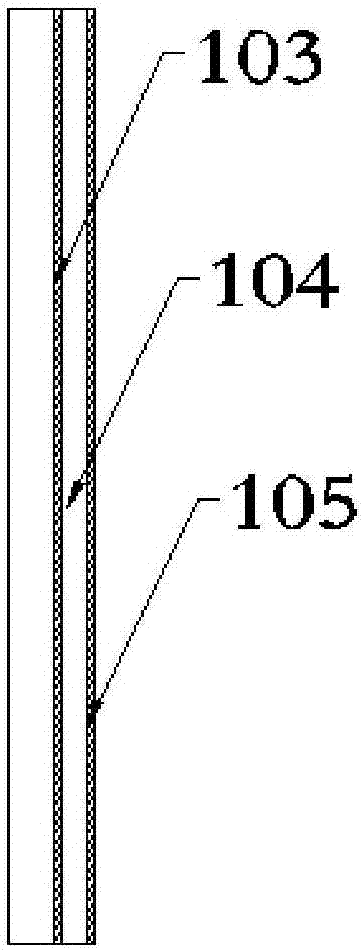

[0114] Such as figure 1 - Figure 6 As shown, this embodiment provides a casing of an electronic device, including a casing body 1, and the casing body 1 sequentially includes a heat sink 101, a heat conduction sheet 102, an inner layer 103 of the casing body, and a hollow cavity 104 from the inside to the outside. and the shell body outer layer 105; the hollow cavity 104 is filled with a phase change material 106, and the phase change material 106 includes capric acid-lauric acid binary composite phase change material.

[0115] The electronic device in this embodiment is a mobile phone.

[0116] Such as figure 2 As shown, the housing body 1 also includes a side wall 107 extending inward from the periphery of the outer layer 105 of the housing body. The outer layers 105 of the housing body are connected smoothly, and the other end is an arc that gradually converges toward the accommodation space. The housing body 1 is provided with a camera reserved hole 108 .

[0117] I...

Embodiment 2

[0126] Different from Example 1, in this example, the weight ratio of capric acid and lauric acid is 1:5, and the volume of the phase change material accounts for 90% of the volume of the hollow cavity.

[0127] The heat sink is a graphite heat sink; the heat conduction sheet is a heat conduction silica gel sheet; the inner layer of the shell body and the outer layer of the shell body are made of copper. Among them, the thermally conductive silica gel sheet is mainly prepared from the following raw materials in parts by weight: 90 parts of magnesium oxide, 2.5 parts of methyl vinyl silicone rubber, 6.5 parts of vinyl silica gel, 9 parts of dimethyl silicone oil, 1-ethynyl-1- 0.25 parts of cyclohexanol and 0.3 parts of platinum catalyst.

[0128] The thickness of the phase change material is 1.0mm, the thickness of the graphite heat sink is 0.1mm, the thickness of the thermal silica gel sheet is 0.2mm, the thickness of the inner layer of the shell body and the outer layer of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com