Pan-tilt structure based on double-parallelogram linkage mechanism

A technology of parallelogram and quadrilateral connecting rod, which is applied in the field of cloud platform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

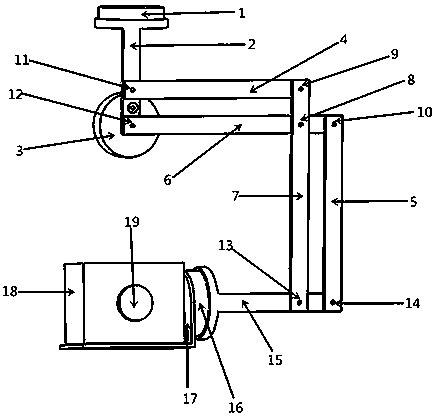

Embodiment 1

[0018] Example 1: Such as figure 1 As shown, the present invention provides a gimbal structure based on a double parallelogram linkage mechanism, which includes a pan axis motor 1, a pan axis connector 2, a roll axis motor 3, a double parallelogram linkage mechanism, and a pitch axis connector 15. Pitch axis motor 16 and bearing member 17. The photographing equipment mounted on the carrier 17 may be a camera, a video camera, and other photographing devices. In this embodiment, the photographing equipment takes the camera 18 as an example to illustrate the beneficial effects of the present invention. The camera 18 can be fixed to the carrier 17 by a locking member. Of course, it is understandable that the shooting equipment can also be other types of cameras or surveillance cameras, etc. The pan / tilt can be used as an auxiliary device for photography, photography, and monitoring, and can be used in manned aircraft, carriers, automobiles, ships, robots, and movies. Shooting and ...

Embodiment 2

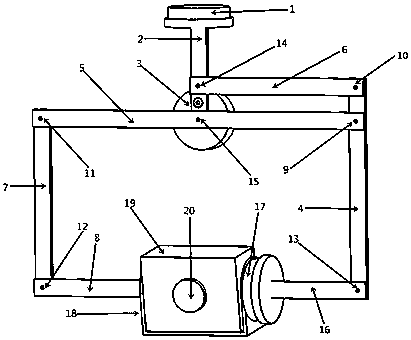

[0024] Example 2: Such as figure 2 As shown, another pan-tilt structure based on a double parallelogram linkage mechanism provided by the present invention includes a pan axis motor 1, a pan axis connector 2, a roll axis motor 3, a double parallelogram linkage mechanism, and a pitch axis connection Piece 16, pitch axis motor 17 and bearing piece 18. The photographing equipment mounted on the carrier 18 may be a camera, a video camera, and other photographing devices. In this embodiment, the photographing equipment takes the camera 19 as an example to illustrate the beneficial effects of the present invention. The camera 19 can be fixed to the carrier 18 by a locking member. Of course, it is understandable that the shooting equipment can also be other types of cameras or surveillance cameras, etc. The pan / tilt can be used as an auxiliary device for photography, photography, and monitoring, and can be used in manned aircraft, carriers, automobiles, ships, robots, and movies. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com