Drilling hydraulic propulsion equipment for geological exploration

A technology for geological exploration and propulsion equipment, applied to drilling equipment, drill pipes, drill pipes, etc., can solve the problems of affecting the hearing of operators, aggravating noise pollution, large mechanical friction, etc., and achieve stable rotation, high degree of automation, and friction in operation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

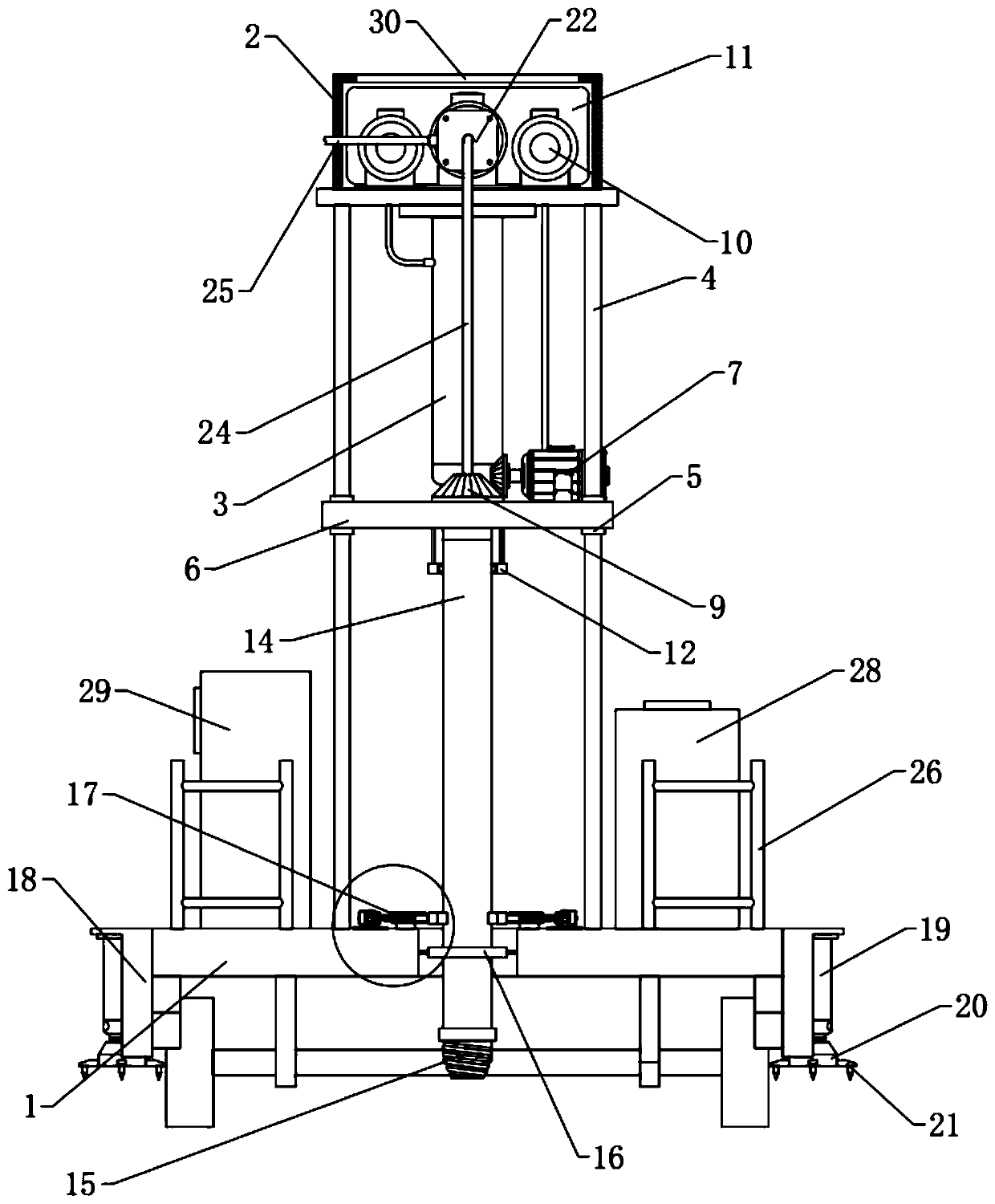

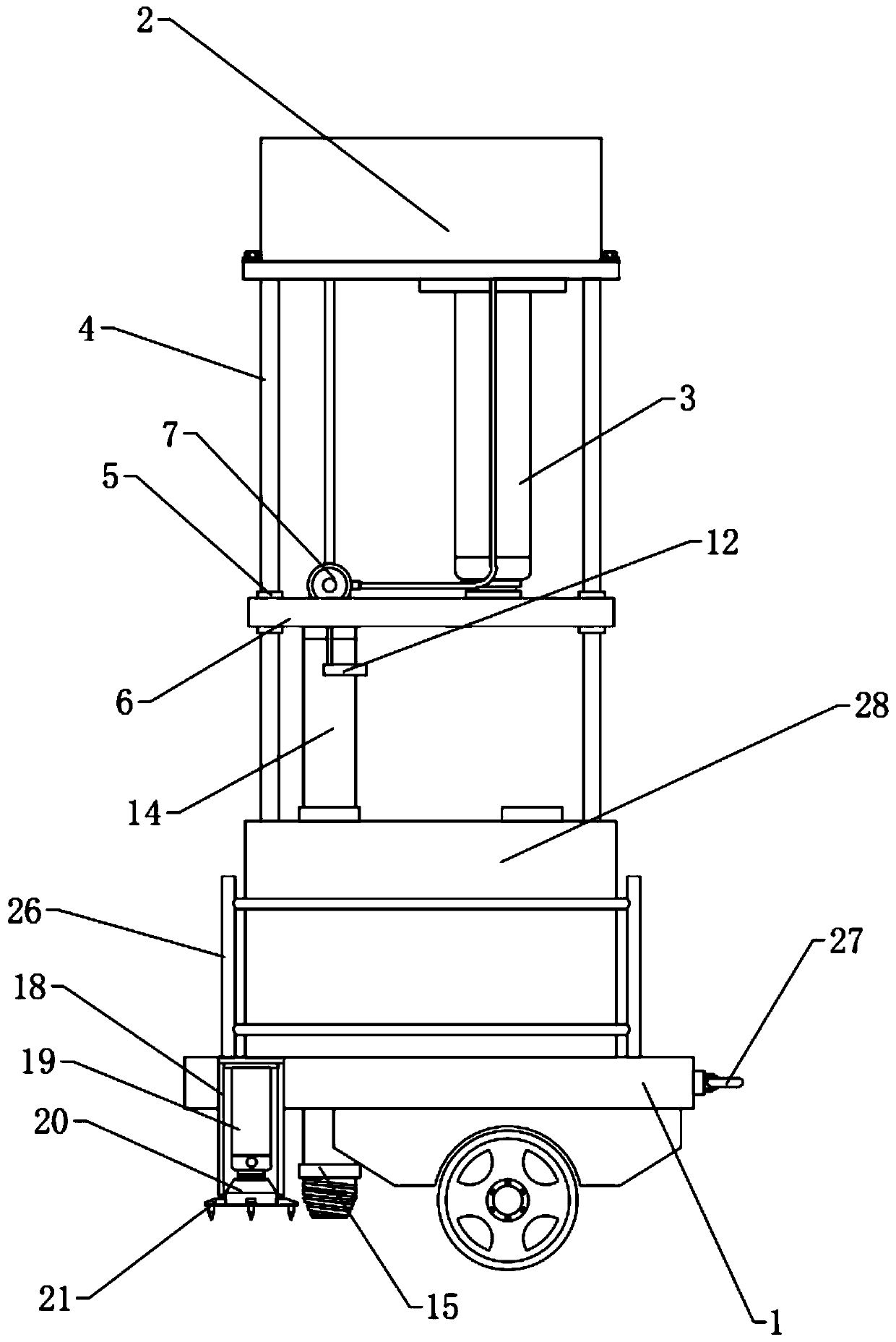

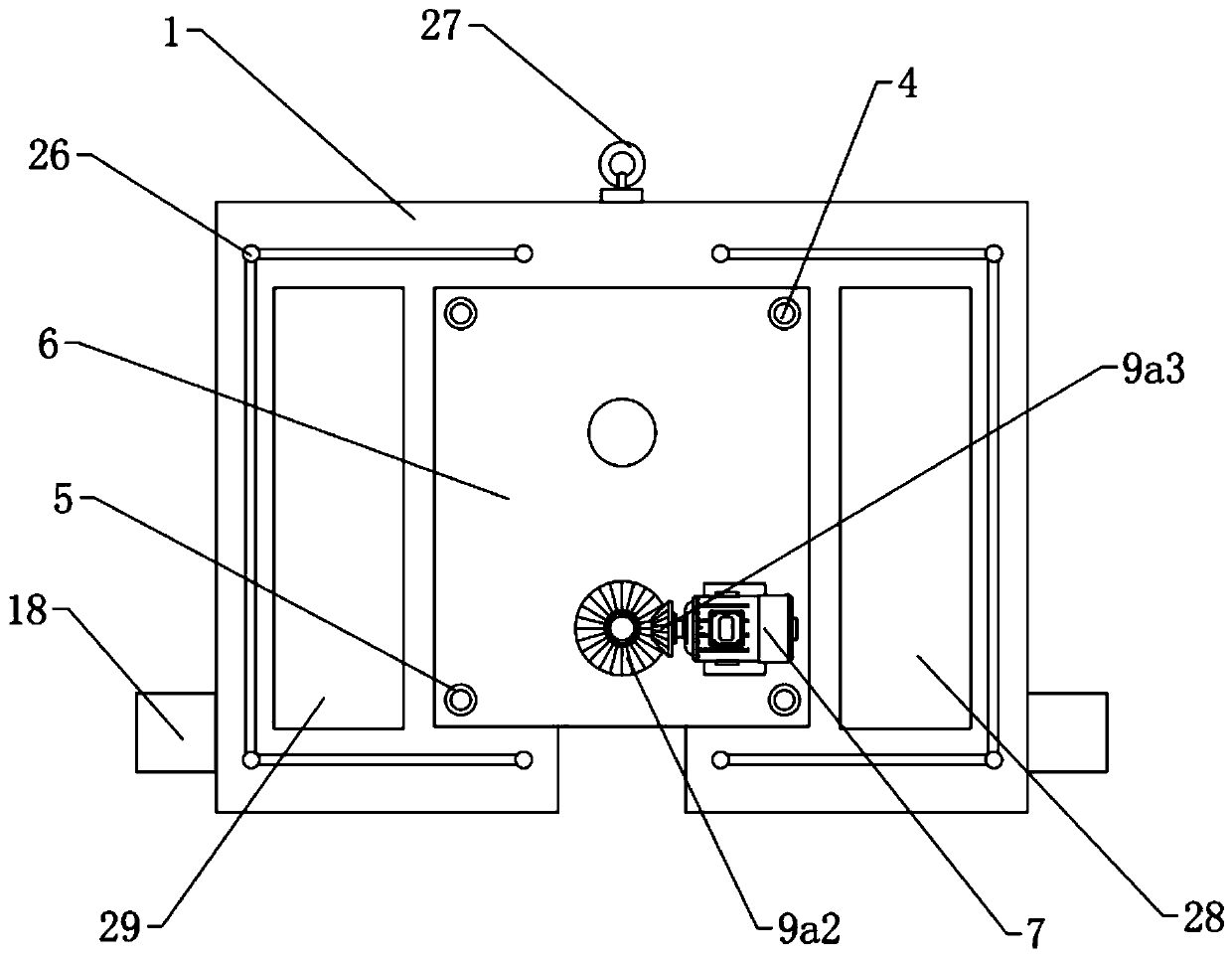

[0038] Example: according to the instructions attached Figure 1-11 It can be seen that this case is a hydraulic propulsion equipment for drilling for geological exploration, including a carrying platform, a drilling mechanism and a mud supply mechanism. The carrying platform is a traction flatbed transport vehicle 1, and the flatbed transport vehicle 1 has a pair of rollers connected by rollers. There is a pair of anchoring components on both sides of the flatbed transport vehicle 1, a drilling groove is provided on one side of the flatbed transportation vehicle 1 and a frame is installed on the drilling groove, the drilling mechanism is installed on the frame, the mud supply mechanism is installed on the flatbed transportation vehicle 1 and Connected with the drilling mechanism, the frame is equipped with a power traction mechanism. In the specific implementation process, the moving mechanism of the carrying platform as the main body is not limited to the traction flatbed tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com