Four-wheeled hand truck capable of achieving pivot steering

A technology of in-situ steering and trolleys, applied to trolleys, multi-axis trolleys, motor vehicles, etc., can solve problems such as inability to achieve 360-degree steering, laborious steering, and prone to safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

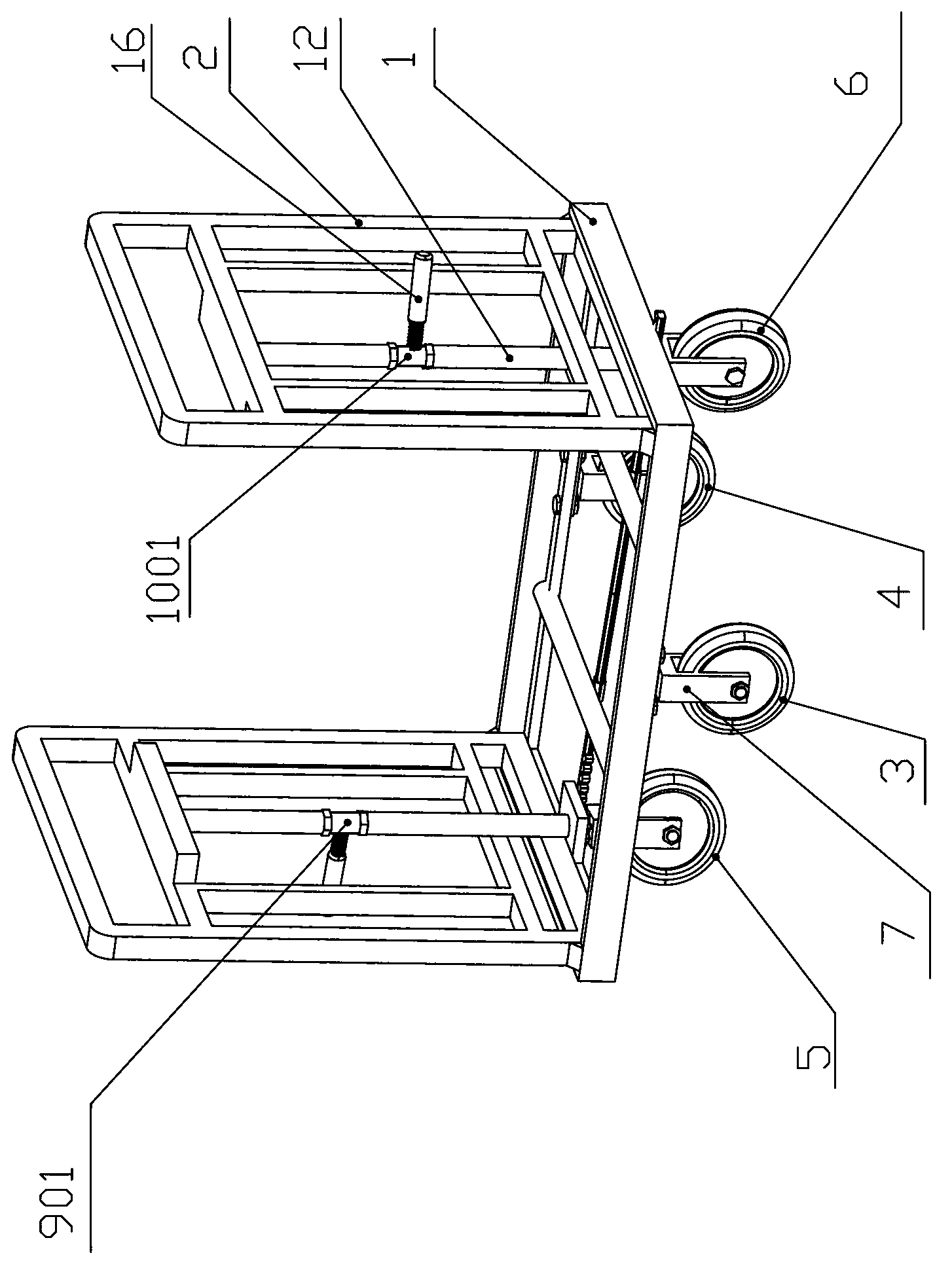

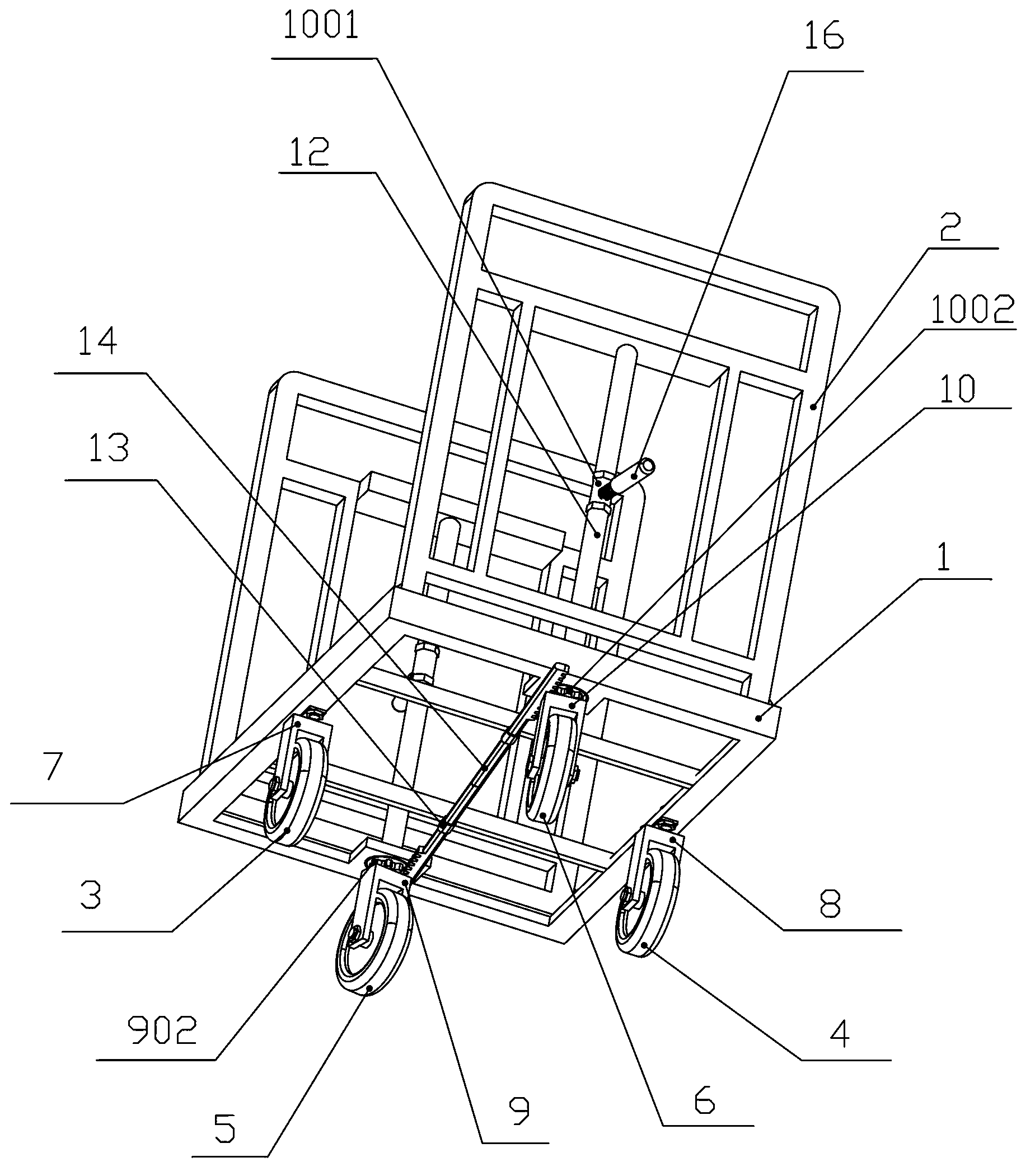

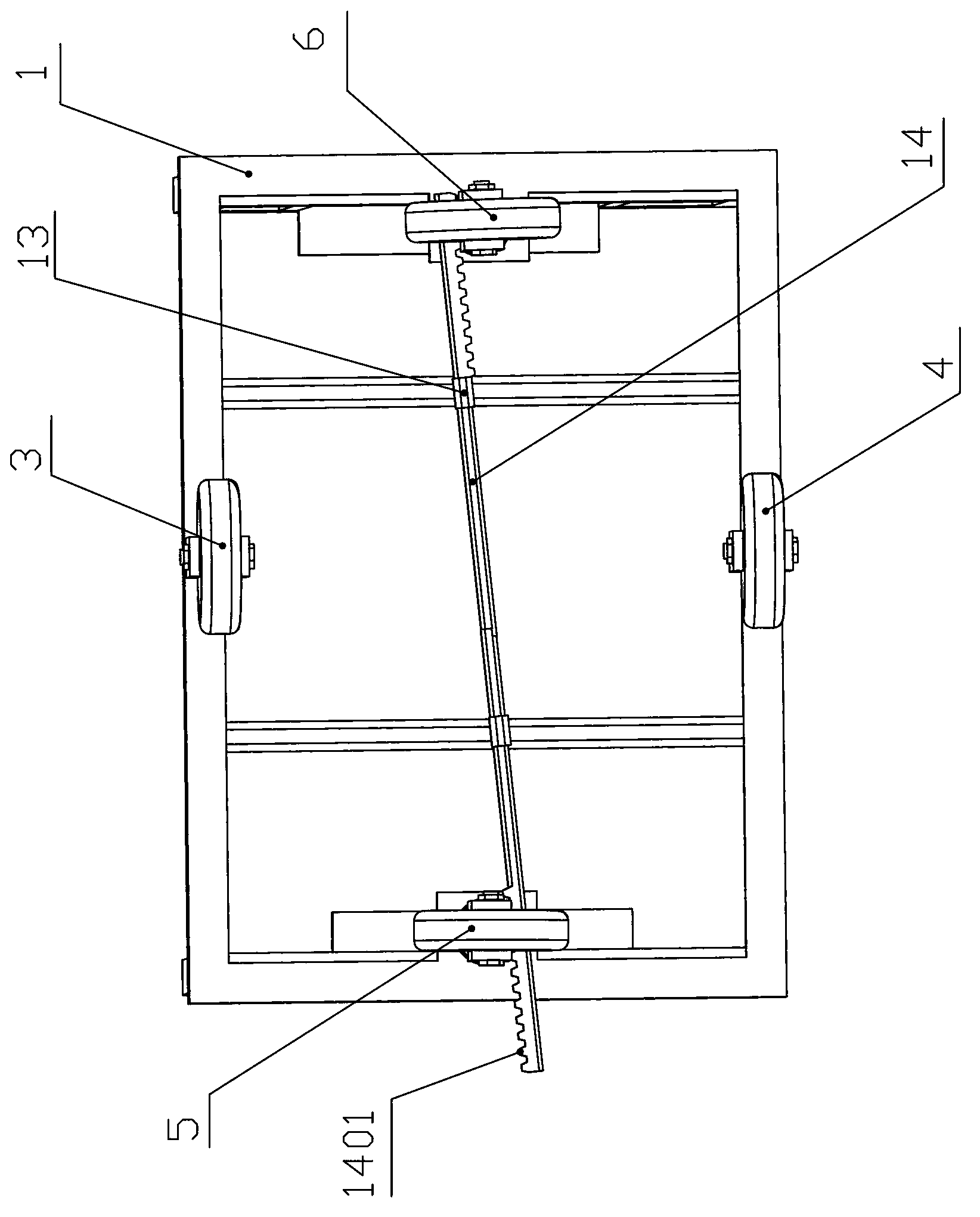

[0013] Such as figure 1 , 2 As shown, the four-wheeled trolley that can be steered in situ includes a frame 1, a handle 2 connected to the frame 1, and rollers arranged under the frame 1, and the rollers include a left roller arranged in the middle of both sides of the frame 1 3, the right roller 4 and the front roller 5 and the rear roller 6 that are arranged in the middle position of the front and rear ends of the vehicle frame 1, and the four wheels touch the ground simultaneously. The left roller 3 and the right roller 4 are fixed rollers, which are fixed in the middle of the bottom of both sides of the vehicle frame 1 by the left roller bracket 7 and the right roller bracket 8; the front roller 5 and the rear roller 6 are respectively installed on the front roller bracket 9 and the rear roller bracket 10 Above, the front roller bracket 9 and the rear roller bracket 10 are respectively provided with a front vertical shaft 901 and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com