Refining process of polyoxymethylene dimethyl ether condensation product

A technology of polyoxymethylene dimethyl ether and condensation products, which is applied in the preparation of hydroxyl compounds, organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., and can solve unsolved separation problems and difficulties in hydrogen recovery Large scale, high refining costs, etc., to achieve the effect of facilitating large-scale continuous production, reducing decomposition problems, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Paraformaldehyde (water content 8%) and methylal according to the molar ratio CH 2 O:DMM=1.2:1 mixed to obtain the condensation raw material, then added to the reaction kettle, and then added the condensation catalyst, the addition amount was 5% of the mass of the condensation raw material. Replace the excess air in the reactor with nitrogen, press it to 1.0MPa, then raise the temperature to 120°C, and react at a stirring speed of 600r / min for 2 hours. After the reaction, filter the catalyst to obtain the condensation product.

[0066] Put the refined catalyst into a fixed-bed refining reactor, and perform reduction pretreatment on the catalyst. The reduction conditions are: 230°C, 0.5MPa, and hydrogen air velocity of 120h -1 , Nitrogen air velocity 480h -1 .

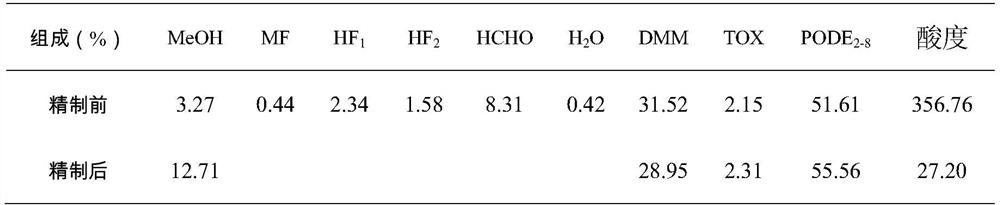

[0067] Then refine the condensation equilibrium product, the process conditions are: reaction pressure 2.0MPa, reaction temperature 120°C, liquid space velocity 1.0h -1 , hydrogen air velocity 50h -1 . The c...

Embodiment 2

[0076] Paraldehyde and methylal according to the molar ratio CH 2O:DMM=1.2:1 mixed to obtain the condensation raw material, then added to the reaction kettle, and then added the condensation catalyst, the addition amount was 2.5% of the mass of the condensation raw material. Replace the excess air in the reactor with nitrogen, then press to 0.6MPa, then raise the temperature to 60°C, and react at a stirring speed of 600r / min for 1h. After the reaction, filter the catalyst to obtain the condensation product.

[0077] Put the refined catalyst into a fixed-bed refining reactor, and perform reduction pretreatment on the catalyst. The reduction conditions are: 230°C, 0.5MPa, and hydrogen air velocity of 120h -1 , Nitrogen air velocity 480h -1 .

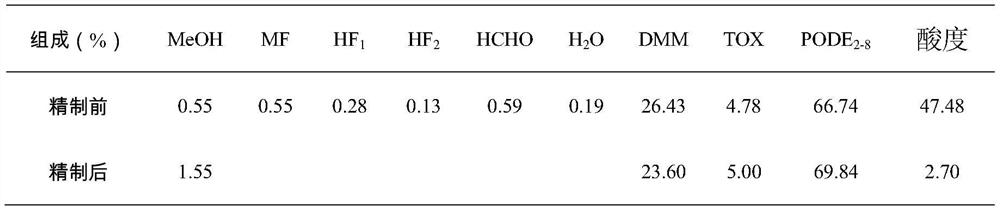

[0078] The condensation equilibrium product is mixed with water according to the mass ratio of 100:0.04, and then refined. The process conditions are: reaction pressure 2.0MPa, reaction temperature 120°C, liquid space velocity 1.0h -1 ,...

Embodiment 3

[0082] Concentrate 37% formaldehyde solution to obtain 85% formaldehyde solution, then mix 85% formaldehyde solution and methylal according to the molar ratio CH 2 O:DMM=1.2:1 mixed to obtain the condensation raw material, then added to the reaction kettle, and then added the condensation catalyst, the addition amount was 7.0% of the mass of the condensation raw material. Replace the excess air in the reactor with nitrogen, then press to 1.5MPa, then raise the temperature to 130°C, and react at a stirring speed of 600r / min for a reaction time of 2h. After the reaction, filter the catalyst to obtain a condensation product.

[0083] Put the refined catalyst into a fixed-bed refining reactor, and perform reduction pretreatment on the catalyst. The reduction conditions are: 230°C, 0.5MPa, and hydrogen air velocity of 120h -1 , Nitrogen air velocity 480h -1 .

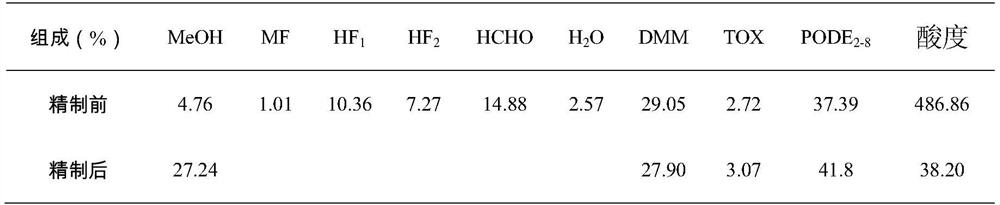

[0084] Then refine the condensation equilibrium product, the process conditions are: reaction pressure 2.0MPa, reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com