Preparation method of silver tungsten carbide contact material

A contact material, silver tungsten carbide technology, used in contacts, metal processing equipment, transportation and packaging, etc., can solve the problems of large consumption of chemical reagents, large sinking speed, clumping and aggregation, etc., to ensure high uniformity, Avoid silver aggregation, fine porosity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Example 1: Preparation of AgWC (60) contacts

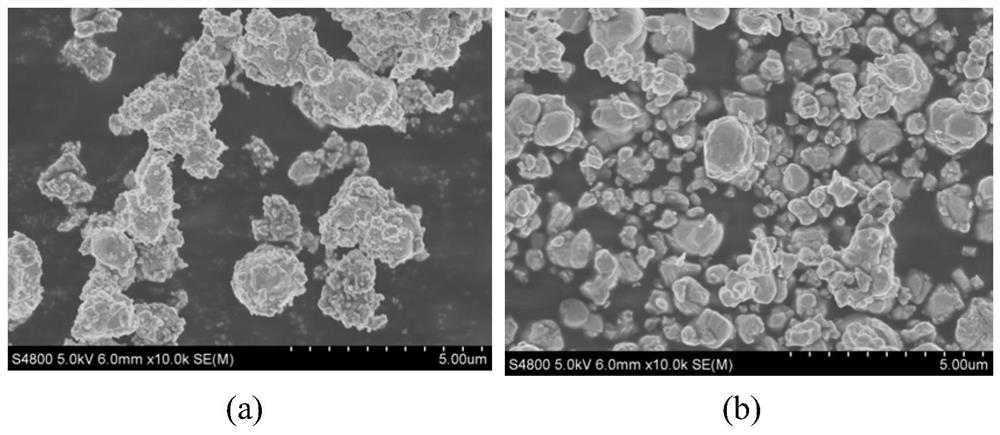

[0038]1) Weigh 3Kg of tungsten carbide powder (average particle size is 2μm, the SEM image is as followsfigure 1 (b) Shown), AgNO30.645kg of crystals, 360mL of deionized water (the solid-to-liquid ratio of tungsten carbide powder and water is 1Kg: 120mL), spare;

[0039]2) Put AgNO3The crystals are dissolved in deionized water to obtain a silver nitrate solution;

[0040]3) Place the tungsten carbide powder in a container, slowly pour the silver nitrate solution into it under stirring, and continue stirring until the silver nitrate solution is completely poured in to obtain a mixture material in which the silver nitrate solution is completely immersed in the tungsten carbide powder;

[0041]4) The obtained mixture is dried in a water bath, the temperature of the water bath is 85°C, and the stirring is continued during the drying process, and the drying time is 5 hours. After taking it out, it is mashed to obtain a dry powder;

[0042]5) Put the ...

Embodiment 2

[0049]Example 2: Preparation of AgWC (70) contacts

[0050]1) Weigh 3Kg of tungsten carbide powder (average particle size of 5μm), AgNO30.414kg of crystal, 231mL of deionized water (the solid-liquid ratio of tungsten carbide powder and water is 1Kg: 77mL), spare;

[0051]2) Put AgNO3The crystals are dissolved in deionized water to obtain a silver nitrate solution;

[0052]3) Place the tungsten carbide powder in a container, slowly pour the silver nitrate solution into it under stirring, and continue stirring until the silver nitrate solution is completely poured in to obtain a mixture material in which the silver nitrate solution is completely immersed in the tungsten carbide powder;

[0053]4) The obtained mixture is dried in a water bath, the temperature of the water bath is 90°C, and the stirring is continued during the drying process, and the drying time is 4 hours. After taking it out, it is mashed to obtain a dry powder;

[0054]5) Put the dry powder in an oven, thermally decompose it at 130...

Embodiment 3

[0059]Example 3: Preparation of AgWC (80) contacts

[0060]1) Weigh 3Kg of tungsten carbide powder (average particle size of 8μm), AgNO30.249kg of crystal, 180mL of deionized water (the solid-liquid ratio of tungsten carbide powder and water is 1Kg: 60mL), spare;

[0061]2) Put AgNO3The crystals are dissolved in deionized water to obtain a silver nitrate solution;

[0062]3) Place the tungsten carbide powder in a container, slowly pour the silver nitrate solution into it under stirring, and continue stirring until the silver nitrate solution is completely poured in to obtain a mixture material in which the silver nitrate solution is completely immersed in the tungsten carbide powder;

[0063]4) The obtained mixture is dried in a water bath, the temperature of the water bath is 95°C, and the stirring is continued during the drying process, and the drying time is 3 hours. After taking it out, mash it to obtain a dry powder;

[0064]5) Put the dried powder in an oven, thermally decompose it at 140°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com